Tata Steel is an innovation driven company, which combines a personal service for customers with a creative flair for developing new ideas, while caring for the communities it serves.

We work closely with our customers and are committed to investing in long-term business relationships to help develop new products and technologies.

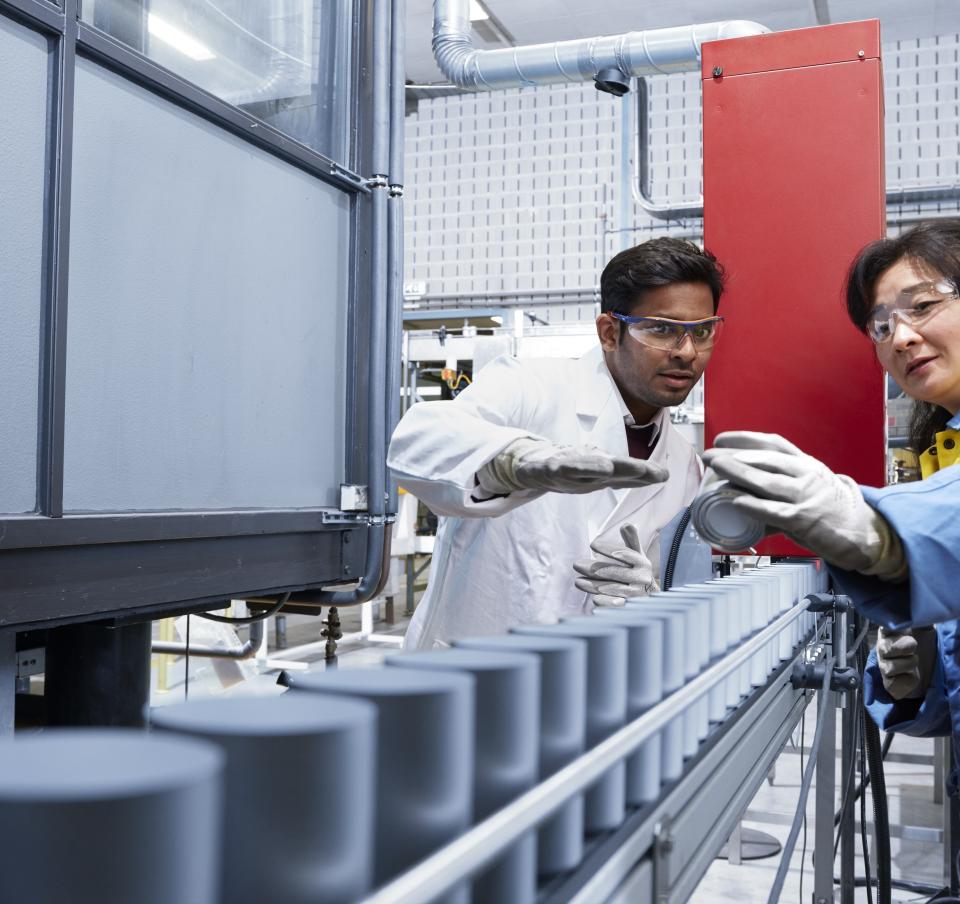

The Research & Development (R&D) business of Tata Steel combines top class innovation with cutting edge technology to deliver ‘metals solutions’ in a constantly changing world.

Our customers are important to us and we work closely with them to ensure they get all the support they need to enable them to design new products and applications.

Nothing is too big a challenge. We use up-to-the minute technology to expand and improve the quality and performance of our steel; we continually upgrade our manufacturing processes and use the latest methods in process analysis and design, product design, modelling/simulation, and prototyping and application development. Our large-scale test facilities permit new products to be tested on an industrial scale, such as can making, production of blanks for car parts, brazing of aluminium radiator elements and corrosion testing of civil constructions.

We employ almost 450 researchers across Britain and the Netherlands, and supply ‘metal solutions’ to Tata Steel sites around the world.

We work in collaboration with universities and research institutes all over the world as well as with key customers in the automotive, transport, packaging and construction areas.

Are you looking for an interesting career with plenty of challenges? Do you have an enquiring mind that is interested in how and why things work? If so, R&D offers you a culture that values your individuality, is open, innovative and will expose you to real and challenging science.

Our future depends on your success. To help you build a successful career we provide a supportive and positive working environment with training, experience and opportunities. Your development is important to us and to support you on your way we provide a tailor-made Talent Development and Management.

Whether you are a recent graduate, HNC level, or already have years of experience, we have some very exciting job opportunities.

To find out more, please visit the Careers section of this site.

At Tata Steel we want to maintain our position as one of the world’s leading steel companies. To do this we have to constantly explore new ways of working with others and identify the best ideas and technologies, wherever they may be.

More can be learned about this on our Tata Steel Innovation Portal.

EN-R&D Contact Details

Contact Details

PO Box 10 000 (3G37)

1970 CA IJmuiden, The Netherlands