Today towards tomorrow

Sustainability and digitalisation are creating a new market for mobility. Autonomous driving, electric vehicles, and data driven technology are increasing efficiency and transparency. These trends are leading to radical new design solutions and fresh requirements for materials and services.

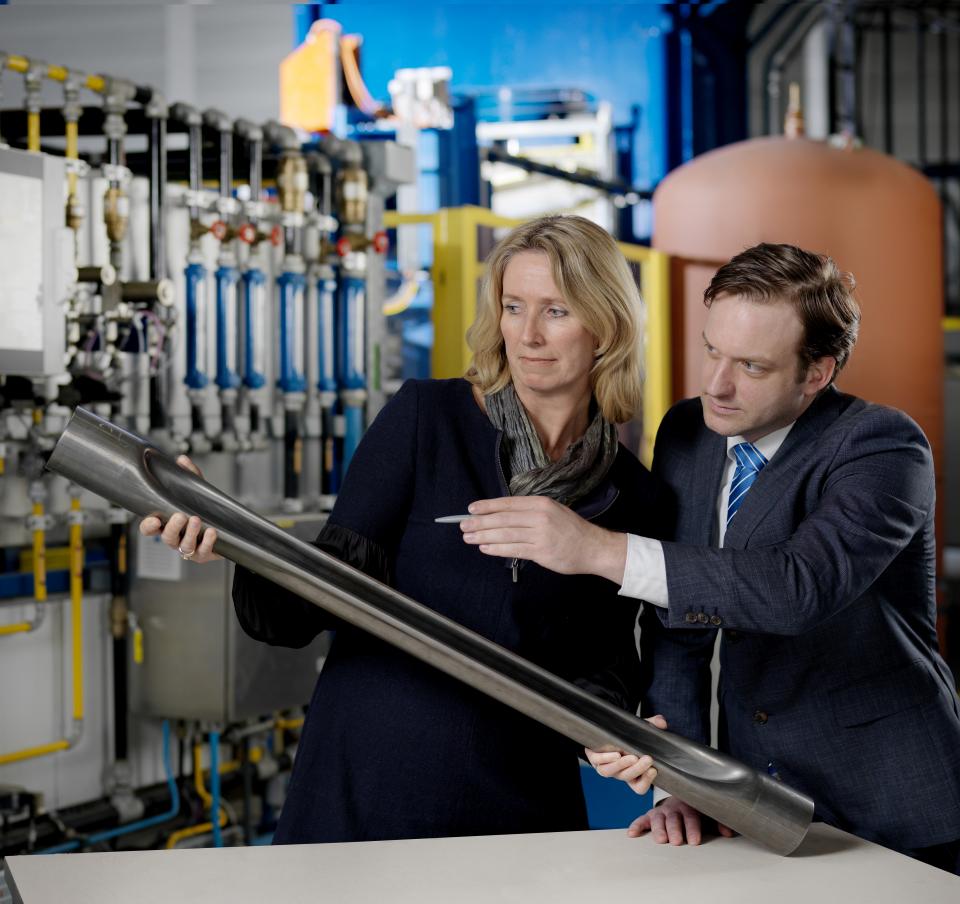

Tata Steel can support you in being successful in this fast changing market. We offer a comprehensive range of sustainable steel solutions tailored to the needs of the new mobility market. Allowing car makers to design and produce high-quality lightweight vehicles, responsibly and transparently.

Join us on our journey with Zeremis and Optemis to a zero carbon emissions and circular world

Find out about our green steel solutions:

Applications

We have knowledgeable experts in all application areas who can work with you to find the right balance between performance, weight, cost and sustainability.

Preferred partner for high efficiency thin gauge electrical steel enabling next generation designs.

Supporting you from concept to series production. Increased energy absorption in BIW parts, reducing weight and costs in electric vehicles.

Spotlight on our key products

EN-Corporate-Sustainability-Zeremis Carbon Lite

Zeremis® Carbon Lite is a declaration-based, low carbon emission steel solution that offering the potential for up to 100% reduction in CO2 intensity.

EN-Automotive-Key Products-Hi-Lite TSUK

Hi-Lite: a thin non-oriented electrical steel for efficient and high-performance electric motors.

EN-Automotive-Key Products-XPF TSN

XPF® for easy lightweighting and improved energy absorption in complex structural vehicle parts.

EN-Automotive-Key Products-HyperForm TSN

Hyperform®: extra formability for lightweight AHSS design. Tackling weight, costs and performance simultaneously.

EN-Automotive-Key Products-MagiZinc Auto TSE

MagiZinc® Auto: advanced hot-dip galvanised coating for inner parts and outer panels.

EN-Automotive-Key Products-PLT TSE

Prime Lubrication Treatment: advanced surface treatment for smooth processing of automotive panels.

EN-Automotive-Contact-General sales - Webformphoto - hub

Automotive sales enquiries and customer services

Please contact us for further information, questions and enquiries. Working together on sustainable vehicles and value chains.