In the highly competitive automotive environment, Tata Steel Plating's cold rolled and electro-plated steel products can help you succeed.

We can help to speed up production, enhance component quality and enable innovative solutions.

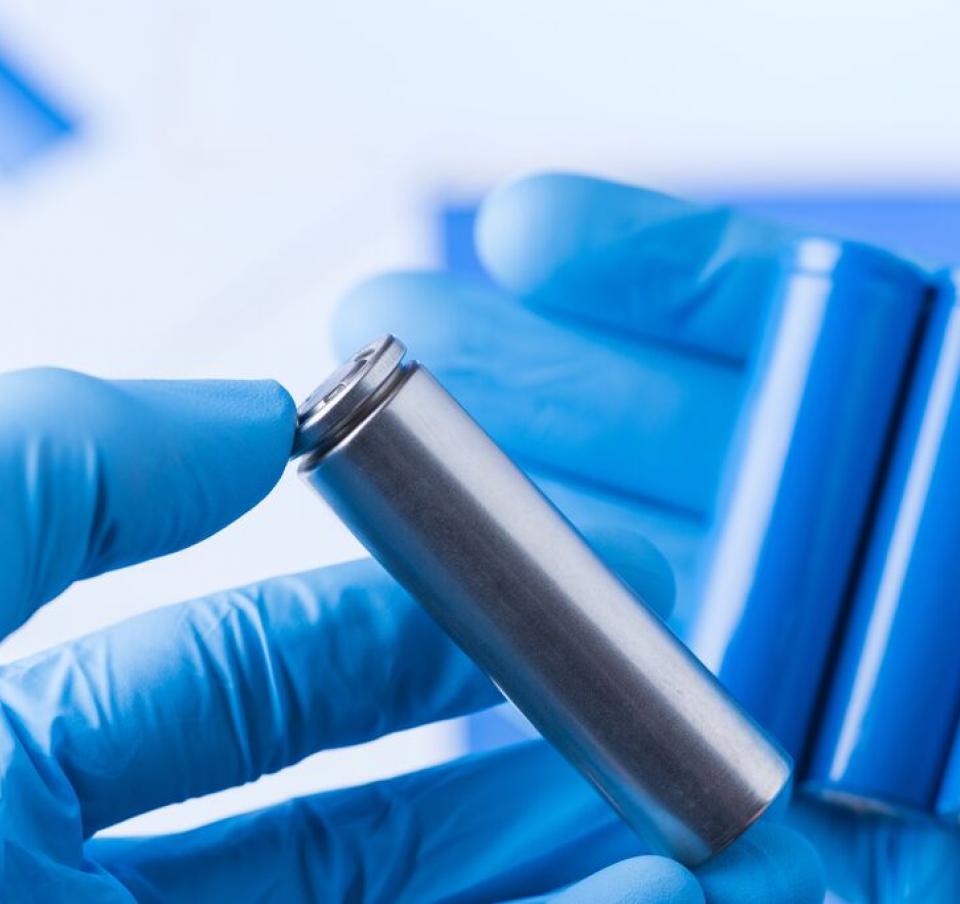

Our electro plated steel products are used for diverse applications in the automotive industry.

These products include:

- Diffusion annealed nickel plated steel for cylindrical battery cells used in electric vehicles (HILUMIN®)

- Copper-plated strip for brake lines and friction materials

- Nickel-plated strip material for fuel lines (NICOR®)

- NiZn-plated strip for head gaskets and other corrosion-resistant applications

- High-precision strip for bearings

Exacting standards

To satisfy the very latest automotive standards, our total quality management (TQM) system ensures compliance with exacting specifications for:

-

tight dimensional tolerances

-

material composition

-

coatings and material thickness

The quality of our pre-plated steel strip gives automotive components the perfect finish and delivers years of reliability.

Product choice

Our comprehensive range of pre-plated steel options means greater design freedom for customers in the automotive industry. Our range includes a wide choice of metallic surface finishes.

Safety and environment

Our products help customers to produce safe and environmentally-friendly cars and automotive components. In addition to being fully recyclable, our cold-rolled and plated steel products offer significant performance benefits. These include:

-

very high levels of corrosion resistance against bio fuels and de-icing agents

-

heat resistance at temperatures over 200 C°

-

outstanding collision performance against leaking or splitting

Tata Steel Plating is a leading provider of electro plated and cold-rolled steel solutions for the automotive industry.

Global reach through

-

2 manufacturing sites in USA (Apollo Metals, Thomas Steel Strip)

-

1 manufacturing site in Europe (Hille & Müller)

-

1 service center in Europe

-

worldwide sales representation

Our development engineers and sales team are here to help you.

For more information please contact us at: TSP.marketing@tatasteeleurope.com

Apollo Metals Ltd

Standard terms of sale & delivery (English)

Purchasing terms & conditions (English)

Hille & Müller

Standard terms of sale & delivery (English)

Allgemeine-Einkaufsbedingungen (Deutsch)

Purchasing terms & conditions (English)

Allgemeine-Verkaufs-und-Lieferbedingungen (Deutsch)

Supplemental terms for acquisitions of machinery and services (English)

Erganzende-Bedingungen-Beschaffung-maschineller-Anlagen (Deutsch)

Anwohnerinformation (Deutsch)

Thomas Steel Strip

Standard terms of sale & delivery (English)

Purchasing terms & conditions (English)

EN-Plating-Engineering-Product-Electro-plated-Copper

Tata Steel offers a range of cold-rolled steel strip products electroplated with copper. These high-performance products are a cost-effective alternative to solid copper. Copper plated steel exhibits excellent brazeability, outstanding formability combined with optimum heat resistance. The deep-drawing properties enable reliable production of components in demanding shapes.

EN-Plating-Engineering-Product-Electro-plated-NICOR

NICOR is nickel electroplated cold rolled diffusion annealed steel strip. For improved deep drawing and easy and reliable processing. It has excellent deep-drawing properties with no risk of surface cracking. The perfect bond between steel and nickel also ensures excellent resistance to corrosion.

EN-Plating-Engineering-Product-Electro-plated-Nickel zinc

Electroplating nickel and zinc creates corrosion resistance that is 4-7 times better than a galvanised coating at an equivalent plating thickness. It offers wide-ranging benefits which include consistent formability and better weldability than zinc-coated products.

EN-Plating-Engineering-Product-Electro-plated-Cold-rolled steel

Tata Steel’s cold-rolled steel strip offers consistent quality that you can rely on. It delivers benefits for your end-products and processes. We can deliver cold-rolled steel in a wide choice of surface appearance to suit your applications. Finish options include Tata Steel’s HIBRITE® - available as a bright finish or mirror finish.

EN-Plating-Contact-Hille and Muller general

General enquiries

Tata Steel Plating

Head Office

c/o Hille & Müller GmbH

Am Trippelsberg 48

D-40589 Düsseldorf