Large or small, we can supply it

From the smallest blanks to the largest sheets, our multi-stand blanking lines and shears allow you to benefit from a full range of products.

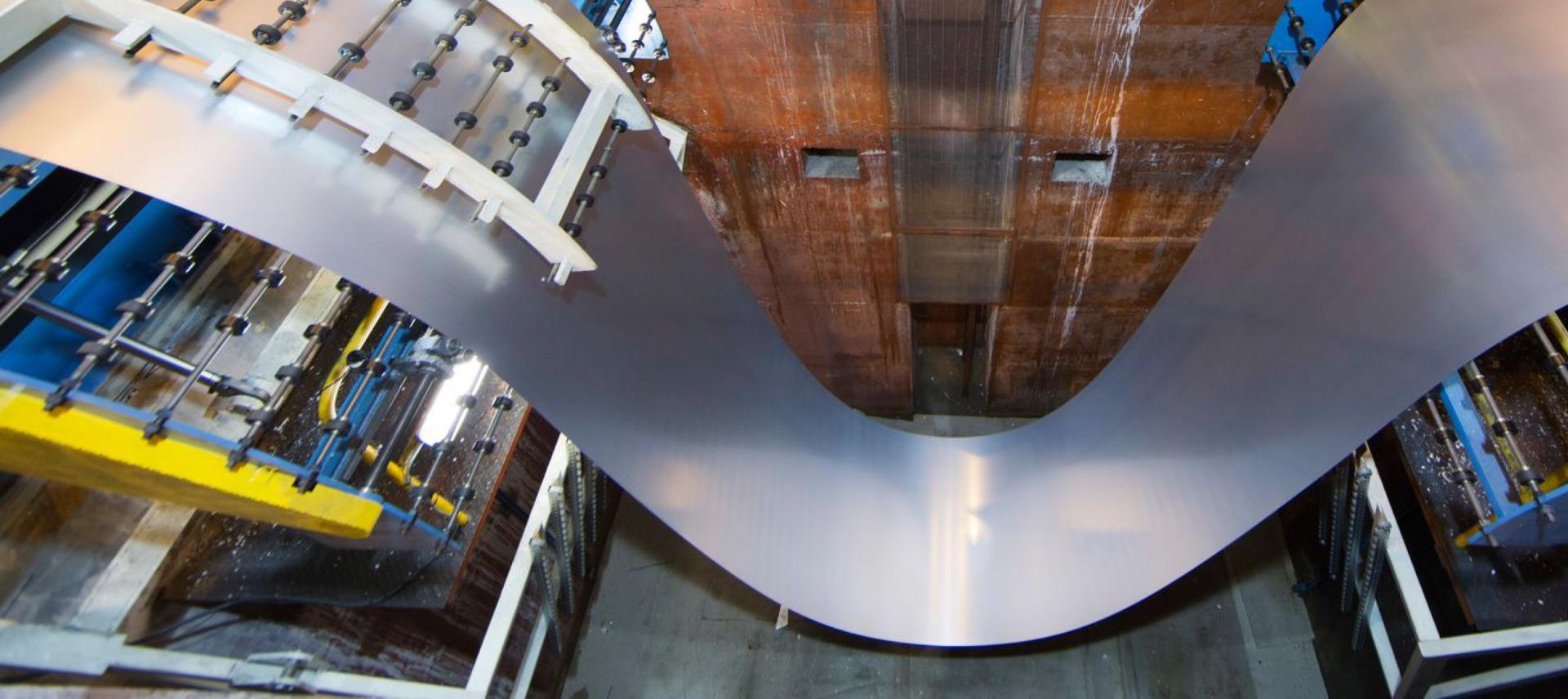

Supplying an extensive range of sheets and blanks of cold rolled, metallic coated and hot rolled specifications, our large-scale decoiling facilities bring the benefits of excellent flatness and surface presentation to customers in the sheet metal and light engineering markets.

Our Light Gauge service centre at Steelpark focuses on the supply of flat sheet for a wide variety of market applications in the sheet metal fabrication and light engineering segments. With 24-hour operations, we can offer regular, flexible nationwide deliveries.

Take advantage of value-adding processing services at Tata Steel’s

service centres.

Processing capability

We offer a unique combination

of six highly-productive multi-strand blankers and two shears for sheet production, all located in one place.

It means we can provide customers with secure supply and sufficient capacity to support your growth plans - without compromising service.

| Thickness | Width | Length | Comments | ||||

|---|---|---|---|---|---|---|---|

| Min (mm) |

Max (mm) |

Min (mm) |

Max (mm) |

Min (mm) |

Max (mm) |

||

| Decoiling | 0.7 | 3 | 900 | 2000 | 700 | 4000 | 2t pack weight |

| Blanking | 0.35 | 3.2 | 600 | 2000 | 420 | 4000 | Minimum blank width = 150mm.Up to 5 strands per coil width |

| Shearing | 0.4 | 6 | 200 | 3050 | 200 | 2450 | Minimum blank size = 20mm.Five high-accuracy shears |

Decoiling

| Thickness: | 0.7 Min(mm) |

3 Max(mm) |

| Width: | 900 Min(mm) |

2000 Max(mm) |

| Length: | 700 Min(mm) |

4000 Max(mm) |

| Comments: | 2t pack weight | |

Blanking

| Thickness: | 0.35 Min(mm) |

3.2 Max(mm) |

| Width: | 600 Min(mm) |

2000 Max(mm) |

| Length: | 420 Min(mm) |

4000 Max(mm) |

| Comments: | Minimum blank width=150mm.Up to 5 strand per coil width | |

Shearing

| Thickness: | 0.4 Min(mm) |

6 Max(mm) |

| Width: | 2000 Min(mm) |

3050 Max(mm) |

| Length: | 200 Min(mm) |

2450 Max(mm) |

| Comments: | Minimum blank size = 20mm.Five high-accuracy shears | |

INVESTING FOR OUR CUSTOMERS

Tata Steel has announced significant investment in its Steelpark distribution and processing facility.

The steel service centre has added a new state-of-the-art versatile blanking line to its capabilities. The new line can process up to four strands of material at a time and creates rectangular, radial and trapezoidal blanks as specified by carmakers and other customers. The versatile blanker processes blanks to tight industry tolerances ensuring minimal material wastage. The processing speed is typically three times faster than existing blanking machines which are being decommissioned as the new investment comes on stream.

This new manufacturing facility can process a wide range of materials at faster run-rates which will in turn reduce lead time expectancies for our valued clients.