Dame Judith Hackitt’s review (Building a Safer Future: Independent Review of Building Regulations and Fire Safety, published in May 2018[1]) of fire safety regulations

The conclusions of Dame Judith Hackitt’s review (Building a Safer Future: Independent Review of Building Regulations and Fire Safety, published in May 2018[1]) of fire safety regulations, made following the tragic fire at Grenfell Tower on 14th June 2017, were clear: the regulatory regime that approved the 2016 refurbishment and recladding of the tower was not fit for purpose, and the industry itself is in need of a radical culture change.

Since publication of the review, some actions have been undertaken – the government has introduced a ban on using any combustible material in the external construction of tall residential buildings, more than 200 buildings have undergone or are undergoing work to replace cladding systems now seen as unsafe and, most recently (June 2019), a consultation has been issued on the practical steps to implement Hackitt’s proposed reforms, including a proposal for a wide-ranging building safety regulator.

Tata Steel’s products are not generally specified for tall buildings above 18m and so are largely unaffected by the ban on combustible materials. Nevertheless, given the continuing uncertainties in the sector, it is important to create clarity for our customers regarding the appropriate use of our products and to ensure that we remain abreast of the current regulations and government advice.

Contents:

-

- Approved Document B (July 2019 revision)

- Amendments to Approved Document B volume 2 and the use of Tata Steel’s products

- Buildings not covered by the ban on combustible materials

- Resisting fire spread from one building to another

- Resisting fire spread over roof coverings

- Internal fire spread

- Fire performance of Tata Steel’s building envelope products and systems.

Approved Document B (July 2019 revision)

Though the planned comprehensive review of guidance on fire safety is still some way from publication, the Government has made amendments to the existing regulations and the updated 2019 edition of Approved Document B[2] (the building regulation in England covering fire safety matters within and around buildings) has now been officially published. The new Approved Document came into force on 30th August 2019.

No new policy has been introduced in the updated Approved Document (the ban on combustibles had already been included in a previous amendment) but some of the text in the document has been rewritten to ensure greater clarity, and a degree of restructuring has also taken place with the design of blocks of flats moved from Volume 2 to Volume 1:

-

-

- Volume 1: Dwellings

- Volume 2: Buildings other than dwellings.

-

Amendments to Approved Document B volume 2 and the use of Tata Steel’s products

The latest edition of Approved Document B sets out the full regulations covering fire safety within and around buildings. However, not all sections of the document, and not all amendments made to it, are relevant to the use of our products. Below, therefore, relevant regulations and amendments are identified, and the appropriate use of our products is clarified.

1. Buildings not covered by the ban on combustible materials

Buildings below 18m and single-storey buildings above 18m, such as warehouses and factories, are not included in the ban on combustible materials.

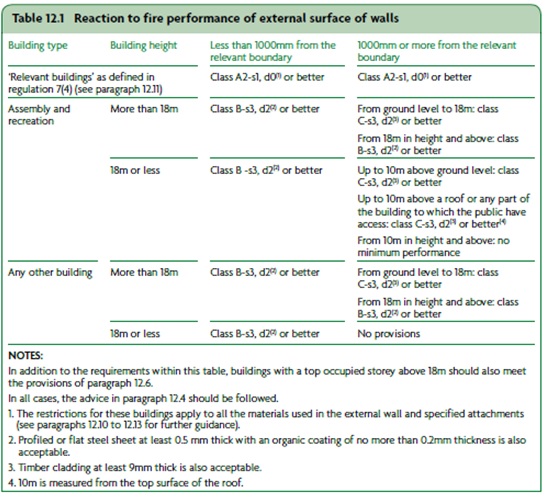

These building types need to use envelope materials with external surfaces (i.e. outermost external material) that comply with the provisions in Table 12.1 in the document, which replaces diagram 40 in the previous version of Approved Document B[2]. The provisions in Table 12.1 apply to each wall individually in relation to its proximity to the relevant boundary.

Note: Table 12.1 is reproduced from Approved Document B[2]

Though most types of multi-storey building above 18m are included in the ban on combustible materials there are a number of exceptions. These include office buildings, hotels, hostels and boarding houses, which are deemed to be lower risk as they have different evacuation strategies.

An addition to the requirements of Table 12.1[2], these types of buildings require that any insulation product or filler material (such as the core materials of metal composite panels, sandwich panels etc) used in the external construction of the wall should be class A2 s3 d2 or better.

An allowed alternative to this would be for the as built construction to meet the performance criteria given in BRE report BR 135 for external walls using full scale test data from BS 8414-1 or BS 8414-2

Fire performance information for all Tata Steel’s envelope products is provided below.

2. Resisting fire spread from one building to another

The fire resistance of a wall depends on its distance from the relevant boundary. Separation distances are measured to boundaries to ensure that the location and design of buildings on adjoining sites have no influence on the building under construction.

The boundary that a wall faces is the relevant boundary It may be one of the following (also see Diagram 13.3 in Approved Document B):

- The site boundary.

- The centre line of a space where further development is unlikely, such as a road, railway, canal or river.

- An assumed notional boundary between two buildings on the same site where either of the following conditions is met.

- One or both of the buildings are in the ‘residential’ or ‘assembly and recreation’ purpose groups (purpose group 1 or 5).

- The buildings will be operated/managed by different organisations.

External Walls

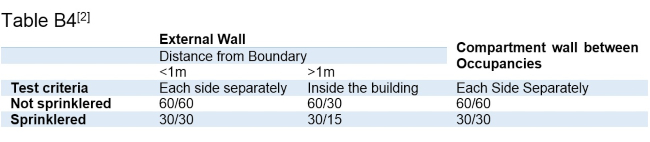

When a wall is less than 1m from a boundary, it must be fire resisting from both sides of the construction. If it is more than 1m from the boundary, the specific requirements are dependent on the building application and the distance from the boundary. In these cases, the fire resistance is only specified from the inside out of the building.

The fire resistance performance is set out in table B4 of the Approved Document B[2].

A summary below shows the minimum fire resistance requirements for commercial, assemble, recreation, industrial and storage single storey buildings. The rates for integrity resistance failure are shown by the first figure and the second relates to resistance to insulation failure.

Compartment walls

For single storey buildings, there are no limits on the size of compartmentation except for shops where the limit is 2000m2, unless a fully automated sprinkler system is fitted in which case there is no limit.

Fire performance information for all Tata Steel’s envelope products is provided below.

3. Resisting fire spread over roof coverings

This section deals with the roof of the building and its adequacy to resist the spread of fire over the roof and from one building to another.

The term ‘roof covering’ is taken in Approved Document B[2] to mean one or more layers of material, but not the roof structure as a whole.

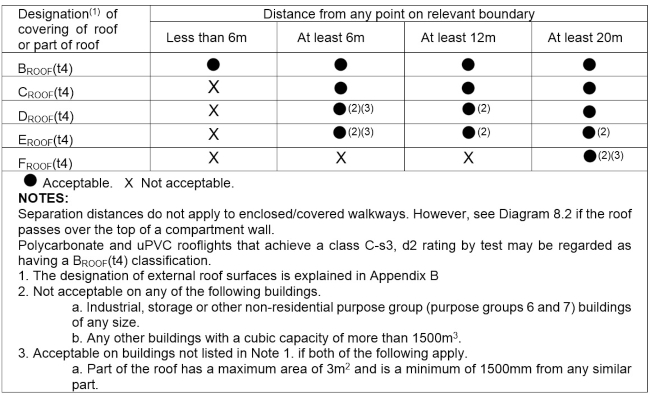

The performance of the resistance of roofs to external fire exposure is measured in terms of penetration through the roof construction and the spread of flame over its surface. Roof constructions are classified in accordance with BS EN 13501-5. This standard classifies the roof construction from BROOF(t4) to FROOF(t4), where BROOF(t4) indicates the highest performance.

The separation distance is the minimum distance from the roof, or part of the roof, to the relevant boundary (described in the previous section). Table 14.1 (from Approved Document B[2], below) sets out separation distances by the type of roof covering and the size and use of the building.

Limitations on roof coverings (Table 14.1 in Approved Document B[2])

Fire performance information for all Tata Steel’s envelope products is provided below.

4. Internal fire spread (linings)

Requirement B2 is the section of Approved Document B[2] that details the fire spread regulations for internal linings. These internal linings are the materials or products used in lining any partition, wall, ceiling or other internal structure.

The Regulations state that to inhibit the spread of fire within the building, the internal linings shall,

- Adequately resist the spread of flame over their surfaces, and

- Have, if ignited, either a rate of heat release or a rate of fire growth, which is reasonable in the circumstances.

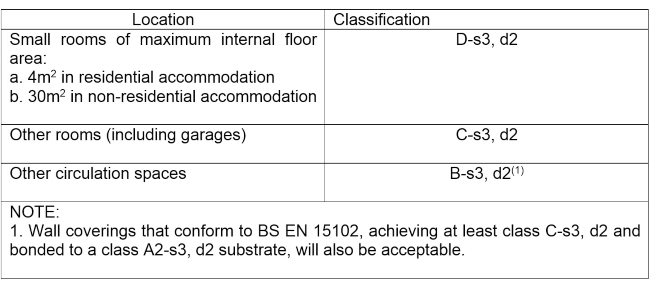

The surface linings of walls and ceilings should meet the classifications set out in Table 6.1 of Approved Document B[2].

Classification of linings (Table 6.1 in Approved Document B[2])

Tata Steel’s systems when using standard bright white enamel internal finishes comply with all locations listed in Table 6.1 of Approved Document B[2]. Fire performance information for all Tata Steel’s envelope products is provided below.

Fire performance of Tata Steel’s building envelope products and systems.

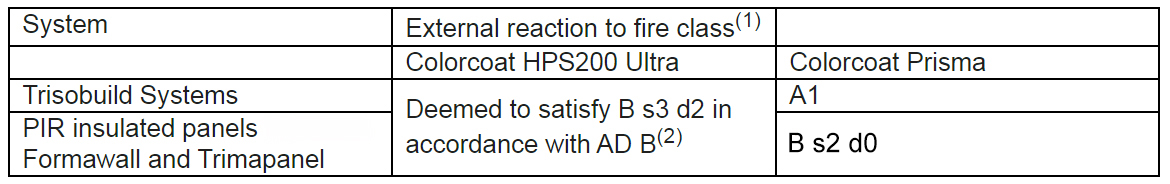

Reaction to fire performance of a walls external surface - in accordance with Approved Document B (fire safety) volume 2: 2019 edition

(1) - Clause 12.5 'The external surface (i.e. outermost external material) of external walls should comply with the provisions in Table 12.1.

(2) - Table 12.1 (Note 2) - Profiled of flat steel sheet at least 0.5mm thick with an organic coating of no more than 0.2mm thickness is also acceptable (ref to Class B s3 d2)

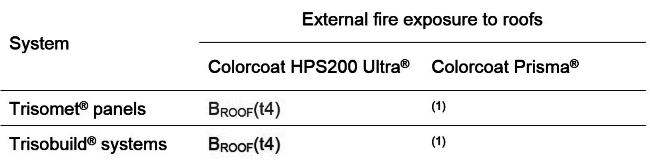

Resisting fire spread over roof coverings - in accordance with Approved Document B (fire safety) volume 2: 2019 edition

(1) - Systems using Colorcoat® Prisma are defined in Commission Decision 2000/553/ EC of 6th September 2000, implementing Council Directive 89/106/EEC and can be considered to fulfil all of the requirements for the performance characteristic ‘external fire performance’ without the need for testing

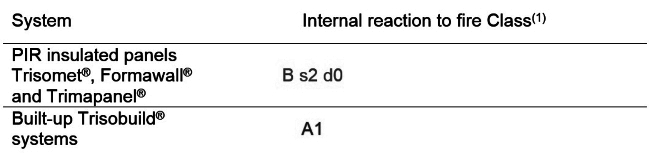

Reaction to fire performance of internal surfaces of walls and ceilings - in accordance with Approved Document B (fire safety) volume 2: 2019 edition

(1) - Assumes a standard internal Colorcoat® PE15 finish

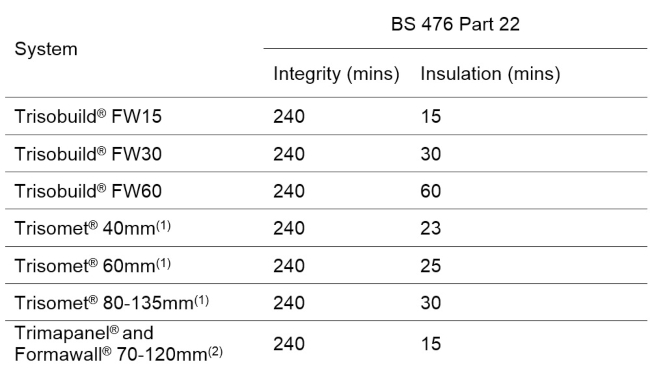

Resistance to fire performance of non-load bearing walls - in accordance with Approved Document B (fire safety) volume 2: 2019 edition

(1) Construction required the external lap stitching to be at a maximum of 300mm centres

(2) The construction required an internal stitching screw (see typical details) at 250mm centres

Find out more about [what tests are used to measure the fire performance of steel cladding systems and how do they measure up in real life?] or [how you can ensure the ‘Golden Thread’ to your project is not broken].

References:

[1] Building a Safer Future: Independent Review of Building Regulations and Fire Safety, published in May 2018

[2]Approved Document B (fire safety) volume 2: 2019 Buildings other than dwellings edition