London Victoria Station

Transport case studies, Trisobuild® curved roof using Colorcoat HPS200 Ultra®

Client: Network Rail

Main contractor: May Gurney

Design engineer: WSP

Installation contractor: Everlast Waterproofing Ltd

Cladding system: Trisobuild® R46, C19, PM13 profiles

Colorcoat® product: Colorcoat HPS200 Ultra®

The challenge

One of the busiest railway terminals in the UK, London Victoria Station is the start or end point for over 70 million journeys a year.

There are effectively four railway stations on the site: two serving main line routes in south eastern England, one underground station serving the District and Circle Lines, and one deep-level tube line station. The Grade II-listed original roofs over the Eastern “Kent” side of London Victoria Station had protected travellers for 150 years, but required extensive renovation.

Network Rail commissioned an up to the minute solution, complementary to the original design, featuring 10,000m² of Building Systems UK (A Tata Steel Enterprise) products.

The solution

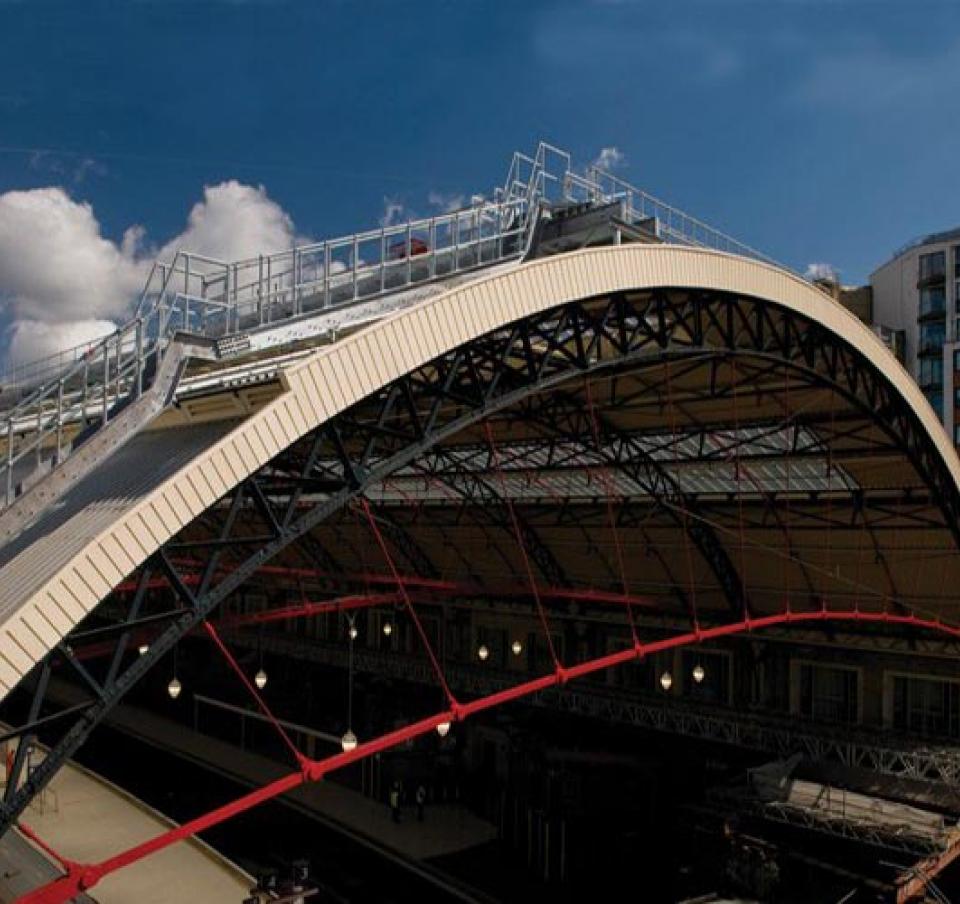

The station has a segment tied arch roof with light iron tie rods arranged polygonally between radian iron struts. Installation contractor Everlast Waterproofing Limited fitted Trisobuild® Systems R46 profile to the two approximately 40 metre spans, over 100+ metre long barrel-vaulted roofs, to a 26 metre radius curve, incorporating stippolyte obscure glazing to match the original patent glazing system.

The replacement roof featured R46 profile in double-sided Colorcoat HPS200 Ultra®, with a Goosewing Grey finish on the external face and a Straw finish on the internal face. The R46 profile was selected by Network Rail due to its ability to span approximately 2.8m from purlin to purlin.

On the concourse, the existing felt roofing laid on timber purlins was replaced by steel purlins and Trisobuild® Systems C19 profile in Colorcoat HPS200 Ultra® in Goosewing Grey, laid over purlins at nominal one metre centres, with an internal PM13 profile in Colorcoat HPS200 Ultra® in Straw, providing a like-for-like tongue and grooved boarding effect when viewed from the underside.

The internal colour choice of Straw was arrived at following extensive research into the concourse colour scheme, to ensure that replacement colours accurately interpreted the original Victorian paints.

Made in the UK to ISO 14001, for a lower carbon footprint, backed by a Confidex® guarantee and available in 40 standard colours, Colorcoat HPS200 Ultra® pre-finished steel combines outstanding performance with unrivalled reliability and impressive sustainability credentials.

EN-Construction-Contact-BSUK envelope

Building Systems UK technical team - Building Envelope