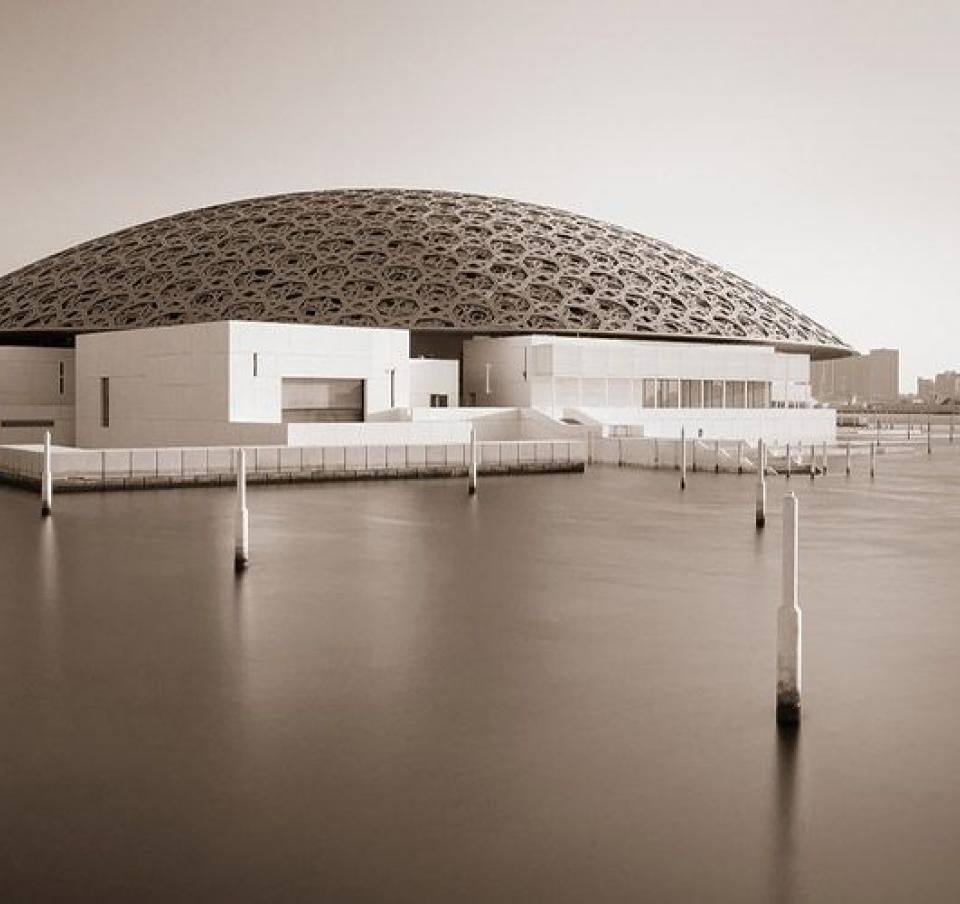

Louvre Abu Dhabi

Leisure case studies, Celsius®

Client: Louvre, Abu Dhabi Tourism & Culture Authority

Architect: Jean Nouvel

Structural Engineer: BuroHappold

Building type: Art Museum

Location: Saadiyat Island, Abu Dhabi

Tata Steel product: 1,900 tonnes of Celsius® square hollow sections

Year: 2017

Image source: Louvre gallery in Abu Dhabi, Img3 (Meetings and geometries) and Img4 (Louvre Abu Dhabi) via thefool0803, Img5 (The Louvre in Abu Dhabi) via Robert Haandrikman

Tata Steel’s Hartlepool plant in the UK has supplied almost 2,000 tonnes of Celsius® square hollow sections to build the vast engineered roof suspended above the new Louvre gallery in Abu Dhabi, which was listed recently as one of BBC Culture’s best buildings of 2017.

The Louvre Abu Dhabi is the first universal museum in the Arab world, born out of an intergovernmental agreement signed between the United Arab Emirates and France. The museum presents both ancient and contemporary works of historic, cultural, and sociological interest from around the world.

The challenge

The key challenge for the creation of the gallery was to construct an eye-catching building that would also protect both the artwork and the visitors from the harsh sun but at the same time allow enough light in to allow daylight viewing of the pieces.

The solution

The crucial contribution to the construction of one of the world’s most impressive new architectural endeavours required 1,900 tonnes of Celsius® square hollow sections being rolled and delivered for the project, working with Alukönigstahl in Austria.

We worked very closely with Buro Happold to ensure the stringent technical requirements were understood. Our technical capability to manufacture steel hollow sections is well proven.

In addition to housing hundreds of precious artworks, the newly-built £1 billion museum in Abu Dhabi is its own work of art.

It features a latticed dome designed to protect visitors from the heat, while allowing the 55 rooms and galleries it covers to experience natural light. Sixty-three supersized elements, made from steel profiles, support the canopy – the size of five football pitches.

Andy Pottinger, Associate Director, Buro Happold, the Design Engineers who specified the premium Tata Steel product, said: “We’re really pleased that a top-quality product has enabled us to realise our vision of the Louvre dome.”

Andrew Ward explained "Tata Steel has a global track record of managing complex project packages. We have executed projects of this nature in the past with extreme precision and accuracy, ensuring achievement of project objectives and client goals.”

EN-Construction-Contact-Tubes-Technical

Structural Hollow Sections Technical Team

Tata Steel

Weldon Road

Corby

Northants

NN17 5UE