Skanska Wave

Commercial case study, Colorcoat Prisma®

*Images Skanska material

Architect: Medusa Architects

Investor/developer: Skanska Property (investor) and Skanska (developer)

Main contractor: Skanska S.A.

Installer: Poko-Al sp. Z o.o

System manufacturer: Metkol Pruszynski sp. z o.o.

Location: Gdansk, Poland

Date: Completed Spring 2020

Tata Steel products: Colorcoat Prisma®

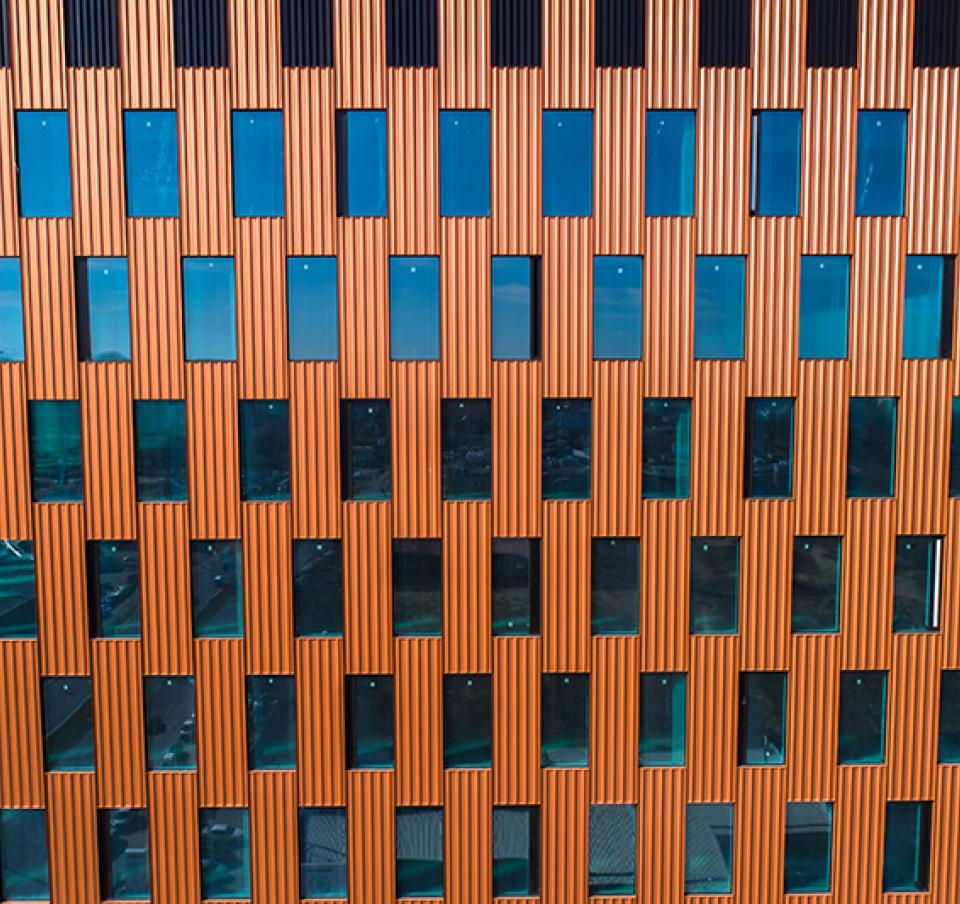

Colour: Seren Copper

Category: Commercial office

The three cities of Gdansk, Gdynia and Sopot, located along the Baltic coast, are inter-connected and form a metropolitan area known as Tri-City or The Triple City. One of the projects ear-marked for this dynamically developing office district in Gdansk is Skanska’s WAVE, a complex of two office buildings, the first of which was completed early June 2020.

Gdansk is one of the most popular destinations in Poland, and part of the rapidly developing Tri-City business area. The eye-catching WAVE is the first of two office buildings planned for this prominent site on Grunwaldzka Avenue in Oliwa, and its construction will contribute to growth in this area. Designed by Medusa Group, the design combines a timeless, industrial architecture with public meeting places that was inspired by the Baltic coast.

The challenge

Forming an integral part of the wider Tri-City, the design brief of the WAVE required a modern office that drew in the inspiring history of Gdansk and would provide a healthy and sustainable working environment. Aesthetics played a key role in its construction and the architects who designed the Wave were inspired by the rhythmic composition of the port container warehouses. In turn, the public area between the buildings draws on its location next to the Baltic coast where the shapes of the dunes and sea worked in close harmony.

Everything about the Wave is ergonomic and green. The design made provision for supporting alternative modes of transport with around 400 parking spaces for bicycles to be created. Both buildings will include cloakrooms and showers for cyclists and runners. Scooter and electric car stations and there will be a virtual reception with special care given to the natural environment and work comfort of the office inhabitants.

Wave is the first office in Tri-City to apply for the extremely demanding WELL certification. Designed in accordance with the WELL certification guidelines the state-of-the-art office will provide a healthy and sustainable workspace. WELL Building Standard® is a certification system developed by IWBI ™ (International WELL Building Institute ™). As part of the certification, seven categories are monitored and evaluated: air, water, nutrition, light, physical condition, comfort and mind.

The solution

The Wave is the first building of two 14-storey, 55m high buildings providing prime office space in an area steeped in history, located next to the Baltic coast and clearly visible on the landscape.

Winning the project was a result of significant collaboration with construction teams on both the side of the cladding system manufacturer based in Poland, as well as Tata Steel. The project’s success was mainly due to the pro-active approach of supply chain partner Pruszynski’s sales team liaising and working closely with the Tata Steel representatives based in Poland, the customer technical services team based in Shotton North Wales, and the end client. This collaboration focussed around two key areas for the client - the aesthetic finish and the sustainability credentials of the chosen products.

In terms of the aesthetics, Pruszynski have a wide range of façade products which they manufacture from Colorcoat® products however, for a building of this magnitude a bespoke cladding solution was needed. The team worked together to produce life size mock-ups of the bespoke profiles in several colours, from which the client chose Colorcoat Prisma® in Seren Copper from the many colour options put forward for the façade

Each of the modules comprised trapezoidal sheets in trays with special flashings protecting each façade element. The profiles were manufactured using around 49 tonnes of Colorcoat Prisma® pre-finished steel in Seren Copper, which clad the external façade, with a small amount used internally. The profiles were lightweight and assembled on site.

The designers also had an objective to follow LEED certification. To support this aim, Tata Steel’s technical team in Shotton produced a detailed report that indicated how Colorcoat Prisma® contributed to maximising points in LEED certification. These credentials included a product specific EPD according to EN 15804, an independent VOC A+ rating and also the product performance benefits in use. Colorcoat Prisma® pre-finished steel not only provides an attractive finish to external façades, but in addition the innovative three-layer product pushes the boundaries for UV performance and outperforms the highest European corrosion resistance standards. This durability significantly reduces the whole life carbon cost of the building.

So complex was the cladding solution that it fell outside standard guarantee offering due not only to the height of the building, but to the complex detailing of the profiles. At the system manufacturers’ request, Tata Steel developed a tailored statement of performance for the project which offered cover for a period of time that the client was happy with.

Due to the location of the site and the extremely restricted access around the buildings as well as the unusual height for steel clad buildings, careful consideration had to be made at the design stage to providing adequate safe access to all areas to facilitate inspection and maintenance of the cladding made from Colorcoat Prisma® during the lifespan of the building.