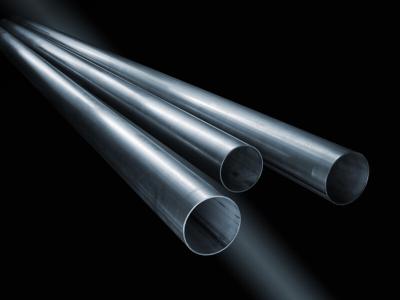

Structural steel

Ymagine® S1 is a direct-rolled, pickled and oiled, structural steel. It provides a viable alternative to cold-rolled and hot-rolled steel and is suitable for a range of production processes. Consistent quality delivers trouble-free processing and helps to maximise yield.

EN-Engineering-Product-Ymagine Direct-rolled-Structural steel-Ymagine S1 TSN

EN-Engineering-Product-Ymagine Direct-rolled-Structural steel-Ymagine S1-Properties TSN

Mechanical properties

The mechanical properties are measured transverse to the rolling direction:

|

Relationship with European standard |

ReH / Rp |

Rm |

A80 |

Adp5 |

|---|---|---|---|---|

|

EN 10025-2: 2004, S235JR |

N/mm² |

N/mm² |

% |

% |

|

t < 3 |

t ≥ 3 |

|||

|

Hot-rolled flat products |

≥ 235 |

360 - 510 |

≥ 17 |

≥ 24 |

|

Ymagine S1 |

Rp |

Rm |

A80 |

Adp5 |

|---|---|---|---|---|

|

|

N/mm² |

N/mm² |

% |

% |

|

t < 3 |

t ≥ 3 |

|||

|

Typical value |

300 |

395 |

28 |

- |

|

Guaranteed values |

235 - 360 |

360 - 510 |

≥ 19 |

24 |

Chemical composition

Cast analysis in weight percentages:

|

Ymagine S1 |

C |

Mn |

P |

S |

Si 1 |

|---|---|---|---|---|---|

|

Typical |

0.045 |

0.220 |

0.008 |

0.007 |

0.018 |

|

Guaranteed (max) |

0.065 |

0.300 |

0.025 |

0.015 |

0.035 |

1. For the purpose of batch galvanising, Ymagine S1 can be ordered on consultation with a maximum Si content of 0.030%.

EN-Engineering-Product-Direct-rolled-Structural steel-Ymagine S1-Dimensions TSN

Dimensions

Dimensions in mm.

|

Thickness |

Ymagine S1 |

|

|---|---|---|

|

from - up to |

Minimum width |

Maximum width |

|

1.15 - 4.00 |

1000 |

1530 |

EN-EngineeringAutomotive-Product-Ymagine Direct-rolled-All grades Shape and dimensional tolerancesTSN

Shape and dimensional tolerances

Tolerances on thickness

Ymagine is available with the following tolerances.

Dimensions in mm:

|

Thickness |

Tolerances |

|---|---|

|

1.15 ≤ t ≤ 2.0 |

± 0.05 |

|

2.0 < t ≤ 2.5 |

± 0.06 1 |

|

2.5 < t ≤ 3.0 |

± 0.07 2 |

|

3.0 < t ≤ 4.0 |

± 0.09 3 |

1. In some instances, the material will be supplied with a tolerance of -0.06/+0.15 mm,

only on the coil head and tail and to a maximum of 20 metres from the start of the coil.

2. In some instances, the material will be supplied with a tolerance of -0.07/+0.17 mm,

only on the coil head and tail and to a maximum of 20 metres from the start of the coil.

3. In some instances, the material will be supplied with a tolerance of -0.09/+0.21 mm,

only on the coil head and tail and to a maximum of 20 metres from the start of the coil.

Tolerances on width

Width tolerances comply with standard EN 10051: 2010 (hot-rolled) and

EN 10131: 2006 (cold-rolled). Closer tolerances are possible – please contact us for details.

Width tolerances for Hot-rolled products

Tolerances in mm.

| Nominal width w | ||||

|---|---|---|---|---|

| Mill edges | Trimmed edges | |||

| lower | upper | lower | upper | |

|

w ≤ 1200 |

0 |

20 |

0 |

3 |

|

1200 < w ≤ 1850 |

0 |

20 |

0 |

5 |

|

w > 1850 |

0 |

25 |

0 |

6 |

Width tolerances for Cold-rolled products

Tolerances in mm.

|

Nominal width w |

Normal tolerances |

Special tolerances (S) |

||

|---|---|---|---|---|

|

Under |

Over |

Under |

Over |

|

|

w ≤ 1200 |

0 |

4 |

0 |

2 |

|

1200 < w ≤ 1500 |

0 |

5 |

0 |

2 |

|

w > 1500 |

0 |

6 |

0 |

3 |

Special width tolerances may be available (± 0.50 mm available on 750 - 2000 mm width). Please contact us for details.

Dimensions and coil weights

The weight of weld-free coils can be specified freely between 13 and 20.5 kg/mm.

Ymagine is supplied with trimmed edges as standard. Mill edges are available on request.

|

Description |

Dimension or weight |

|---|---|

|

Outside diameter |

minimum 1050 mm maximum 2000 mm (Ymagine) maximum 2100 mm (mill scale) |

|

Coil Weight |

maximum 31.5 tonne 1 |

1. For Ymagine H500 the maximum coil weight is 25 tonne for thicknesses > 2.5 mm.

Above 3.20 mm maximum coil weight for all grades is 25 tonne. Higher coil weights available on request.

Tata Steel assumes a minimum and a maximum coil weight agreed upon with the customer on the basis of our normal production practices and an order quantity corresponding to this coil weight. Usually a minimum coil weight up to 90% of the maximum coil weight can be requested.

Surface aspects

The surface quality of Ymagine is comparable to hot-rolled pickled and oiled i.e. 1 - 3 μm Ra (cut off 2.5mm).

Ymagine is suitable for cold-rolled applications that are not surface-critical.

EN-EngineeringAutomotive-Product-Hot-rolled-Heavy+Light further processing TSE

Further processing

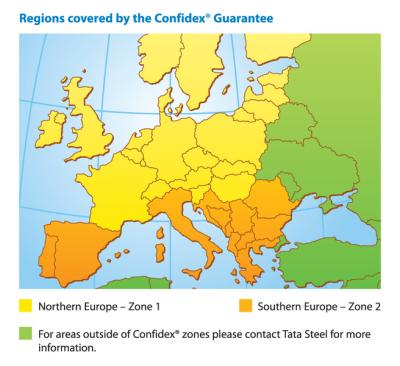

We have a broad network of Tata Steel service centres across Europe, offering decoiling and slitting services from stock and against short lead times.

Heavy gauge processing

| Processing type | Decoiling |

|---|---|

| Thickness range (mm) | 1.4 - 25.4 |

| Width range (mm) | 300 - 2600 |

| Length range | up to 18.4 m |

| Locations | Netherlands |

Light gauge processing

| Processing type | Slitting | Decoiling | Blanking |

|---|---|---|---|

| Thickness range (mm) | 0.2 - 7.0 | 0.3 - 6.0 | 0.3 - 6.0 |

| Width range (mm) | 10 - 2050 | 50 - 2600 | 200 - 2600 |

| Length range | - | up to 6 m | up to 6 m |

| Locations | Netherlands Germany France Spain Sweden Norway Finland |

Netherlands Germany France Spain Sweden Norway Finland |

Netherlands |

For further information please visit our Service Centre webpages.