The pressure is on to reduce development times in the automotive industry

Fast, accurate material data from your steel supplier can give you the competitive advantage by saving time and cost acquiring material data and by enabling more accurate simulations for reduced tool try-out time and no surprises during crash testing.

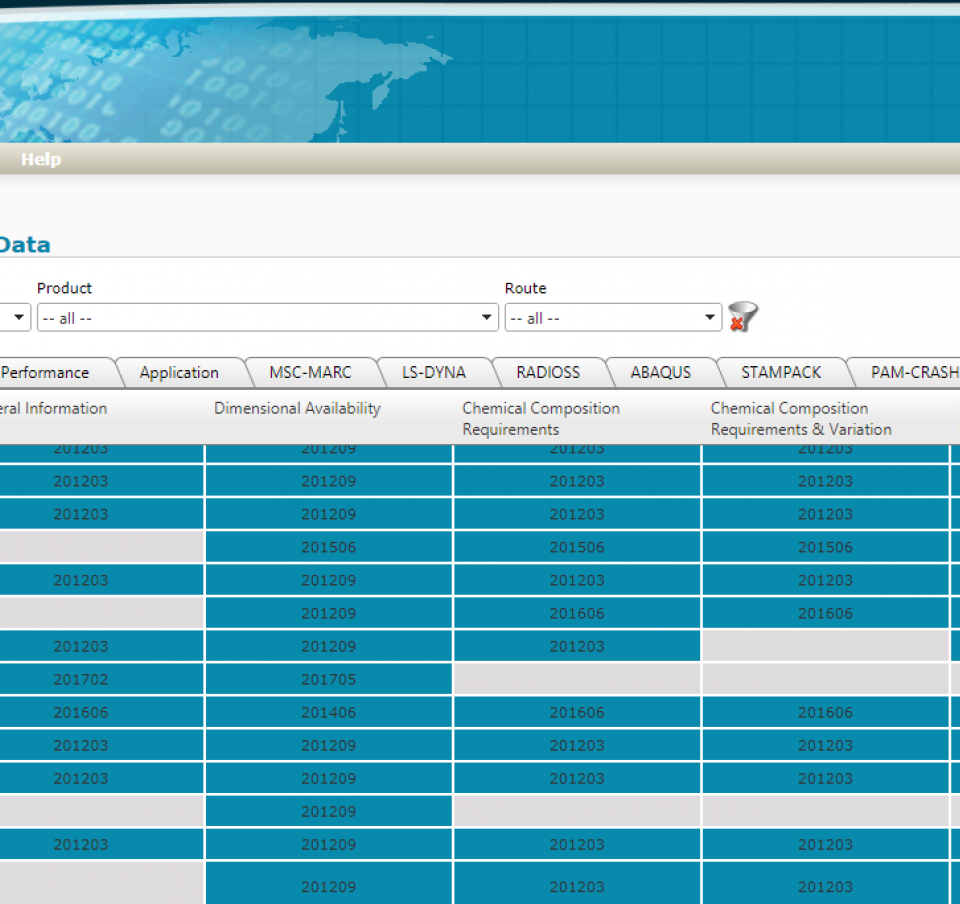

What’s in Aurora® Online?

- Tata Steel's automotive product range

- High quality data, representative of production material, developed and maintained by our experts

- Full range of material properties such as forming, joining, fatigue and crash data

- New product data sets to speed up material evaluation and assessment for application in new vehicles

- Access to most up-to-date material data and information on new grades for early evaluation

- Material data sheets available as both raw basic data (Excel data sheets) and ready-to-run input decks for the most commonly used FEA packages, saving time in feasibility assessments

- Expert support: where you have a specific challenge our experts are there to support you to set up the simulation and evaluate the results.

More accurate simulations for smoother tool try out and testing

Aurora Online offers our customers on-demand access to representative material data and advanced material models to predict and enable accurate simulations for reduced tool try-out time and no surprises during crash testing. Using advanced material data and plasticity models and with the support of our world leading R&D experts on material plasticity, you can set up accurate and reliable forming and crash simulations that reduce lead times and lower expenditure on materials testing during the development of new vehicles and tooling.

Aurora Online provides data sets that depict the actual steel properties, and not simply the specification limits. With all data available in easy-to-read Excel data sheets and in ready-to-run input deck format, customers no longer need to fit yield loci, forming limit curves and hardening curves themselves.

That's how this powerful tool will save you hours in setting up accurate, reliable simulations. The ready-to-run input decks are available for the most commonly-used forming software packages including:

- AutoForm

- LS-DYNA

- PAMSTAMP (ESI Group)

- PAMCRASH (ESI Group)

- Stampack Xpress

- Radioss

- MSC Marc

- Mentat/Simufact Forming

Instant access to material data when you need it for material assessment

The Aurora Online database is instantly and easily accessible, ensuring accurate and consistent data whenever you want it, without having to call suppliers or test samples, making it ideal for urgent requests. It also offers access to the most up-to-date material data and information on new grades for the early evaluation of new materials.

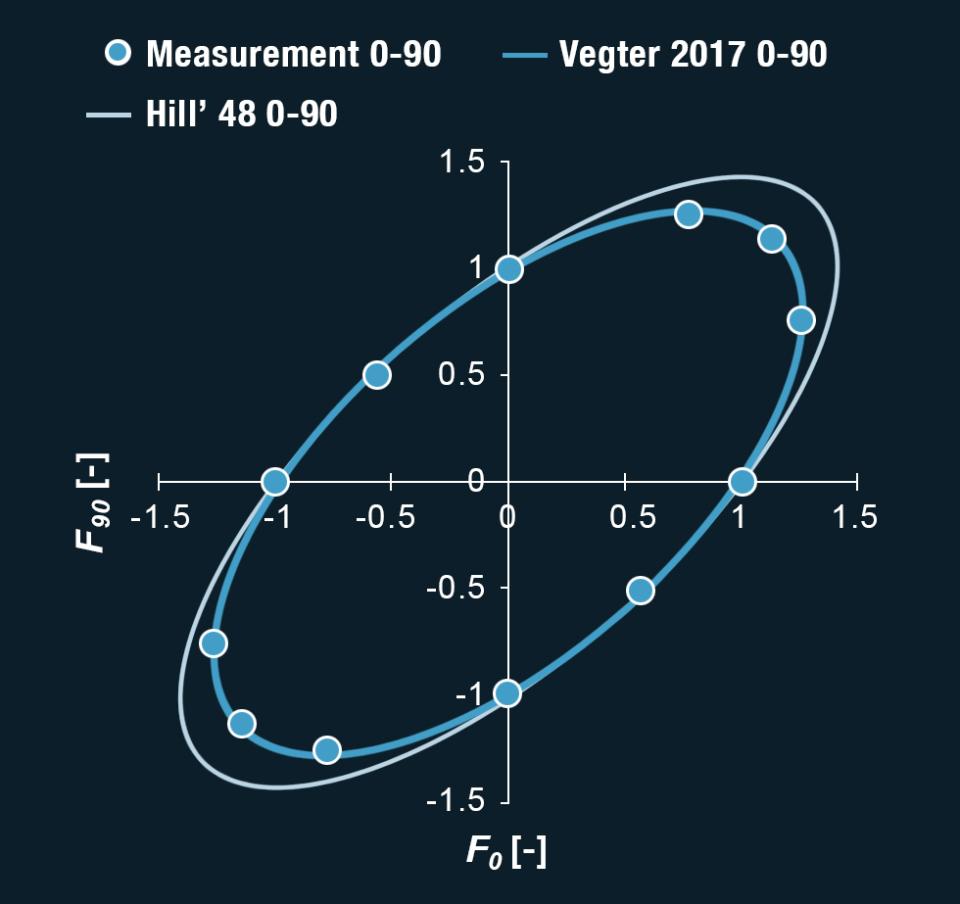

Highly accurate advanced material models

Accurate simulations are not only about high quality data, but also realistic material models. Tata Steel's R&D has experts dedicated to the development of representative material models for all material types. Examples include:

- Vegter 2017 Yield Locus: a new method for predicting advanced yield criteria input parameters from tensile properties

- Abspoel & Scholting Forming Limit Curve: an efficient and reliable method for predicting forming limit curves from tensile properties in 0°, 45° and 90°

Aurora Online contains both input data and ready-to-run decks to facilitate easy use of these models. You can achieve the most accurate simulation result with a minimal amount of experimental input data:

- no need for special tests (biaxial, plane strain and shear stress points)

- as easy as Hill’48 and Keeler, but much more accurate

FEA suppliers AutoForm, LS-DYNA, MSC Marc and Mentat, PAM-CRASH (ESI Group), PAM-STAMP (ESI Group) and Stampack Xpress have implemented Vegter (2017) in their software allowing you to use the same material models globally. The Abspoel & Scholting Forming Limit Curve is implemented in AutoForm. For other packages the data can be imported as tabulated data.

Getting access

Tata Steel offers Aurora Online to its valued customers to support fast evaluation of new products, to access advanced material cards for accurate simulations and to enable joint simulation projects. Click here to apply for access. Information on how we process your data can be found in our privacy statement.

Supported by experts in simulation/modelling

The excellent reliability and accuracy of Aurora Online’s advanced material data and plasticity models is thanks to Tata Steel’s Innovation Centre, a world leading authority on material plasticity.

Tata Steel’s experts in material data and modelling are there to support Aurora Online users with specific challenges by advising on simulation set up and evaluation to get the most realistic results.

- Getting access to Aurora material database: email connect.automotive@tatasteeleurope.com

- Publication list

| Title | Journal / Conference | Author(s) |

| A plane stress yield function for anisotropic sheet material by interpolation of biaxial stress states | International Journal of Plasticity 22 (2006), p. 557 | H. Vegter, A.H. van den Boogaard |

| A new method for predicting advanced yield criteria input parameters from mechanical properties | Journal of Materials Processing Technology, Volume 248, October 2017, Pages 161–177 | M. Abspoel, M.E. Scholting, M. Lansbergen, Y.G. An, H. Vegter |

| A new method for predicting Forming Limit Curves from mechanical properties | Journal of Materials Processing Technology, Volume 213, Issue 5, May 2013, Pages 759–769 | M. Abspoel, M.E. Scholting, J.M.M. Droog |

| Accurate anisotropic material modelling using only tensile tests for hot and cold forming | IOPSCIENCE Journal of Physics: Conference series, Volume 896 Conference 1 (IDDRG 2017) | M. Abspoel, M.E. Scholting, M. Lansbergen, B.M. Neelis |

| Analytical and experimental study of frictional behavior in through-thickness compression test | Journal of Materials Processing Technology 160 (2005) 148–155 | Y.G. An, H.Vegter |

| A novel and simple method for the measurement of plane strain work hardening | Journal of Materials Processing Technology 155–156 (2004) 1616–1622 | Y.G. An, H. Vegter, L. Elliott |

| Development of simple shear test for the measurement of work hardening | Journal of Materials Processing Technology 209 (2009) 4248–4254 | Y.G. An, H. Vegter, J. Heijne |

| Experimental analysis of strain path dependent ductile damage mechanics and forming limits | Mechanics of Materials, Volume 41, Issue 11, November 2009, Pages 1264-1276 | C.C. Tasan, J.P.M.Hoefnagels, C.H.L.J. ten Horn, M.G.D.Geers |

| Inherent influence of strain path in Nakazima FLC | IDDRG 2011 | M. Abspoel, E.H. Atzema, J.M.M. Droog, T. Khandeparkar, M.E. Scholting, F.J. Schouten, H. Vegter |

| Testing methods for fracture modelling | Werkstoffprüfung 2009 | C.H.L.J. ten Horn, M.P.J. Lambriks, K. Unruh |

| Thermomechanical forming and crash simulations | IOP Conference Series: Materials Science and Engineering | M Abspoel , M E Scholting and M Lansbergen |

| Improved plane strain prediction and easy to use 3D extension for Vegter 2017 yield locus | Forming Technology Forum 2022, Enschede | M Abspoel , M E Scholting, M Lansbergen and J. Mulder |

- Downloads