Colorcoat Prisma®

Aesthetics that last, guaranteed.

Colorcoat Prisma® demonstrates a step change by utilising cutting edge three layer manufacturing technology to create an optimised, robust, chrome free pre-finished steel product.

This development in manufacturing and extensive testing, allows us to offer Colorcoat Prisma® in a greatly enhanced range of colours and effects, Confidex® guaranteed for up to 40 years, and colour stability for up to 20 years for standard colours.

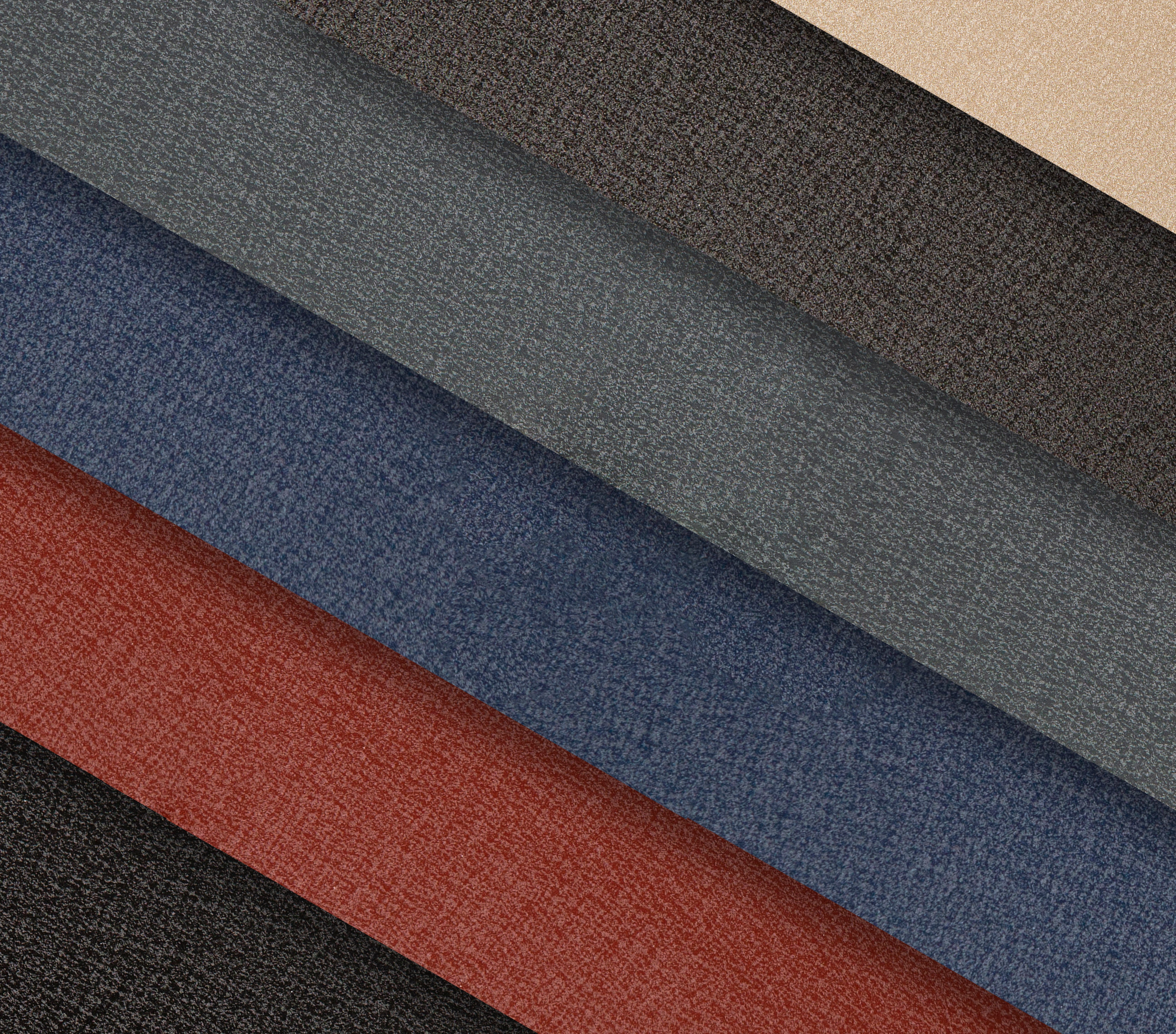

The contemporary colour range includes the Elements selection of natural metal colours, enhanced metallic sparkle effects, as well as a wide selection of inspired Matt shades such as Matt Metallics ideal for facade applications.

Colorcoat Prisma® not only uniquely pushes the boundaries for UV performance but also outperforms the highest European corrosion resistance standards. This makes it the ideal choice for commercial, retail, warehouse, public sector and superior aesthetic buildings that are truly built to last...

EN-Construction-Product-Colorcoat Prisma-default

EN-Construction-Product-Colorcoat Prisma | Benefits

- Revolutionary 3 layer coating technology, providing enhanced aesthetics and long term performance and durability.

- Confidex® Guarantee for up to 40 years for the weatherside of industrial and commercial buildings with no inspection or maintenance to maintain its validity.

- Colour guarantee included as part of the Confidex® Guarantee for standard colours.

- Optimised Galvalloy® metallic coating for ultimate corrosion resistance and cut edge protection.

- Independently tested for liberation of volatile organic compounds (VOC) against EN ISO 16000-9 and achieved an A+ rating.

- Creative and aesthetic range of colour effects available, including Metallic, Sparkle, Matt and Matt Metallic options ideal for facade applications and now a new Textured finish - see separate tab for more details.

- Contemporary colour range offering complete design flexibility with complementary colours and natural metal shades

- Fully REACH compliant & free of chromates including hexavalent chrome.

- Made in the UK. Certified to BES 6001 Responsible Sourcing Standard.

- Fully supports BREEAM & LEED certification.

- Robust and durable topcoat for easier handling and processing.

- Reverse side branding making traceability easy.

- Informed colour choice based on availability, feasibility and level of guarantee via Colorcoat® Compass digital colour matching system.

- Available from a range of Colorcoat® supply chain partners.

If you have any questions or for further information click here to contact us.

EN-Construction-Product-Colorcoat Prisma | Typical properties

| Properties | Test Standard | ||

|---|---|---|---|

| Nominal organic coating thickness Solids, Metallics, Matts Elements |

(μm)* (μm)* |

65 40 |

EN 13523-1 EN 13523-1 |

| Specular gloss (60°): Solids, Metallics Matts Elements |

(%) (%) (%) |

25-35 <10 30-40 |

EN 13523-2 EN 13523-2 EN 13523-2 |

| Scratch resistance: Solids, Metallics, Matts Elements |

(g) (g) |

>3000 >2500 |

EN 13523-12 EN 13523-12 |

| Abrasion resistance (Taber CS10 2x 1kg, 250 Rev): Solids, Metallics, Matts Elements |

(mg) (mg) |

<15 <15 |

EN 13523-16 EN 13523-16 |

| Flexibility: Minimum bend radius Reverse impact Adhesion (Cross hatch) Pencil hardness |

(T) (J) (%) |

0.5T@16°C ≥18 100 H |

EN 13523-7 EN 13523-5 EN 13523-6 EN 13523-4 |

| Maximum continuous operating temperature |

(°C) | 90 | |

| Corrosion resistance: Salt spray Humidity |

(h) (h) |

1000 5000 |

EN 13523-8 EN 13523-25 |

| Corrosion resistance category |

RC5+ | EN 10169:2022 | |

| UV resistance category |

Ruv5 | EN 10169:2022 | |

| Internal environment clarification |

CPI5 | EN 10169:2022 |

*μm = micron

Notes

1. The figures contained in this table are typical properties and do not constitute a specification. Tested in accordance with EN 13523.

2. For health and safety datasheets contact the Colorcoat Connection® helpline.

If you have any questions or for further information click here to contact us.

EN-Construction-Product-Colorcoat Prisma | Product performance

Galvalloy®

Colorcoat Prisma® uses the unique and proven Galvalloy® metallic coating by Tata Steel. Galvalloy® is made with a special mix of 95% Zinc (Zn) and 5% Aluminium (Al) that conforms to EN 10346:2015. The carefully developed proportions of Zinc and Aluminium in Galvalloy® offers a combination of increased barrier and sacrificial protection when compared with conventional Hot Dip Galv (HDG) coatings and provides unrivalled corrosion protection, even at the cut edges.

FIRE PERFORMANCE

Reaction to fire

Colorcoat Prisma® including Colorcoat Prisma® Element colours have been tested to EN 13823 and EN ISO 1716 and can be classified in accordance with EN 13501-1 as A1. This classification is valid for all gauges >0.4mm for all colours in the product range for single sided product.

Performance of roof coverings

Colorcoat Prisma® including Colorcoat Prisma® Element colours are deemed to satisfy, without the need for further testing, the requirements for external fire performance of roof covering products in accordance with Commission Decision 2000/553/EC. This is valid for all gauges >0.4mm and for all colours in the product range for single and double sided products.

UV Resistance

All colours surpass requirements of Ruv5 as per EN 10169:2022 proving outstanding colour retention.

Corrosion resistance

All colours surpass requirements of RC5+ as per EN 10169:2022 proving outstanding corrosion resistance for external building cladding systems.

Natural weathering

Natural weathering testing is an essential part of testing the corrosion resistance of a pre-finished steel product. Colorcoat Prisma® has undergone a comprehensive programme of testing in key weathering climates around the world.

Exposure sites were chosen in order to provide the full spectrum of weathering zones from equatorial and tropical climates to urban, rural, industrial and coastal locations.

British Board of Agrément Certificate

The long-term performance of Colorcoat Prisma® has been recognised within the BBA certificate 91/2717 and relates to the product use as external roofing and cladding or internal lining. “Colorcoat Prisma® coating and metal treatment will protect the steel substrate against corrosion for a period in excess of 40 years in normal industrial, urban and rural environments”.

Testing according to Russian GOST standards

Colorcoat Prisma® has been tested by MISIS in Russia which concluded that when used in difficult climatic conditions (e.g. coastal areas) of medium aggressive environments, it should have its functional and aesthetic properties unchanged in Southern and Northern Russian regions with temperatures ranging from +60 to -60 degrees C.

U-mark certification

Colorcoat Prisma® is being tested by the Karlsruher Institut für Technologie according to DIN 55634.

ASTM

Colorcoat Prisma® has also been tested according to a variety of key ASTM test standards for corrosion and UV resistance. For markets that require ASTM test results please contact us.

ITB

The performance of Colorcoat Prisma® has been validated in Poland by the Institute of Building Technology (ITB). This validates the category RC5+ and the UV resistance in the RUV5 category according to PL-EN 10169:2022 for the standard Solid, Metallic and Matt colours in the range.

Colour consistency

If tonal consistency is critical, all cladding for a single elevation should come from the same production batch. All metallic shades exhibit a degree of directionality.

Matching components

If accessories made from other materials are to be colour-matched to the roof or wall cladding, the best reference is the actual profiles or panels delivered to site, or material from the same batch.

Metal hand samples

Metal hand samples are available for all colours. For a truer representation of colour and effect, please obtain metal hand samples.

If you have any questions or for further information click here to contact us.

EN-Construction-Product-Colorcoat Prisma | Hand samples

Our hand samples can assist in colour selection and finalising product specification. Metal hand samples are available for all colours. For a truer representation of colour and effect, please obtain metal hand samples.

Order samples online for Colorcoat Prisma® here or by contacting the Colorcoat Connection® helpline +44 (0) 1244 892434.

EN-Construction-Product-Colorcoat Prisma | The Confidex® Guarantee

For over 25 years the Confidex® Guarantee from Tata Steel has remained best in class. Confidex® is the product performance guarantee for Colorcoat HPS200 Ultra® and Colorcoat Prisma®, when used in an external conventional building envelope application namely roof and wall cladding using single skin, built-up or composite panel construction in industrial and commercial buildings.

Confidex® offers the longest and most comprehensive guarantee for pre-finished steel in Europe.

If you have any questions or for further information click here to contact us.

EN-Construction-Product-Colorcoat HPS200 Ultra | Register the Confidex® Guarantee

Please complete the online form to register the Confidex® Guarantee for Colorcoat HPS200 Ultra® and Colorcoat Prisma®.

This form can be used to register the Confidex® Guarantee for Zone 1 and Zone 2.

Please click here to register for the Confidex® Guarantee

Transferring the Confidex® Guarantee

A registered Confidex® Guarantee is transferable in the event of sale or transfer of owner or tenant of a building. Please contact the Colorcoat Connection® helpline.

Note: Confidex® must be registered within 3 months of the building completion date for the guarantee to be valid.

If you have any questions or for further information click here to contact us.

EN-Construction-Product-Colorcoat Prisma | Sustainability

At Tata Steel we are committed to making the products society needs and to making them in the most responsible way. Our commitment to sustainability also means we actively manage our impacts and contribution throughout the full life of our products - with our suppliers, within our own operations, through the supply chains we serve and by taking responsibility for recycling steel. Colorcoat Prisma® has achieved BES 6001 responsible sourcing certificate which reinforces our commitment to sustainability.

Life Cycle Assessment

We constantly strive to ensure that the manufacturing processes and materials used to manufacture Colorcoat Prisma® are the most sustainable available. Moreover, the enhanced robustness and durability of Colorcoat Prisma® mean that it significantly outperforms other pre-finished steel in terms of environmental impacts over the full life cycle. To demonstrate the environmental impacts, Tata Steel have published an Environmental Product Declaration (EPD) for each of the Colorcoat® assessed cladding systems, based on an initial Life Cycle Analysis.

System environmental assessment

In the UK all roof and wall systems using pre-finished steel achieve a Green Guide A+ rating. Manufacture and processing of Colorcoat Prisma® into building envelope products, through our approved supply chain, can meet the responsible sourcing criteria for BREEAM. Our manufacturing site has an environmental management system which has been certified to ISO 14001.

Recycling

Colorcoat Prisma® is truly recyclable without any loss of quality, time after time. There is a well established and very efficient steel recycling infrastructure which ensures that all steel collected at end of life goes back into steel manufacture. Through this efficient recycling of steel, the environmental investment in steel-making is never wasted, making steel the most sustainable construction material.

If you have any questions or for further information click here to contact us.

EN-Construction-Product-Colorcoat Prisma-downloads

Product Downloads

EN-Construction-Datasheet-Colorcoat Prisma Textured Datasheet

Colorcoat Prisma® - Textured datasheet

EN-Construction-Approval_or_Certificate-Colorcoat Prisma BBA certificate

Colorcoat Prisma BBA certificate

EN-Construction-Site_instruction-Colorcoat Inspection and maintenance manual

Colorcoat® Inspection and maintenance manual

EN-Construction-Approval_or_Certificate-Colorcoat Prisma Elements Ruv5 certificate

Colorcoat Prisma® Elements Ruv5 certificate

EN-Construction-Approval_or_Certificate-Colorcoat Prisma Solid Metallic Matts Ruv5 certificate

Colorcoat Prisma® Solid, Metallic and Matts Ruv5 certificate

EN-Construction-Site_instruction-Colorcoat PV Installation Guidelines

Colorcoat® PV Installation Guidelines

EN-Construction-Certificate-BES 6001-Colorcoat

BES 6001 Certificate - Colorcoat products

EN-Construction-Approval_or_Certificate-Colorcoat Prisma Anthracite RC5+ certificate

Colorcoat Prisma® Anthracite RC5+ certificate

EN-Construction-Approval_or_Certificate-Colorcoat Prisma Elements Seren Gold RC5+ certificate

Colorcoat Prisma® Elements Seren Gold RC5+ certificate

EN-Construction-Approval_or_Certificate-Colorcoat Prisma Zeus Matt RC5+ certificate

Colorcoat Prisma® Zeus Matt RC5+ certificate

EN-Construction-Approval_or_Certificate-Colorcoat Prisma Zeus RC5+ certificate

Colorcoat Prisma® Zeus RC5+ certificate

EN-Construction-Book a CPD

We offer a range of face to face and online CPDs aimed at Engineers and Architects

These free seminars can be booked at any time between 9am and 5pm. Our online webinars can all be delivered via Skype for Business and Teams, but we can consider other platforms if this will not work for your practice.

Below outline the CPDs we have available - Book yours today

- Decarbonising your structural hollow section designs

- Essentials of Structural Hollow Sections

- Welded Joints in Tubular Steelwork - Eurocode 3 Part 1-8

- Concrete Filled Hollow Sections - Composite Design – Eurocode 4

- Composite Floor Deck in Construction

- Structural Roof Deck in Construction

- Specifying metal clad envelope systems in accordance with ADB2 of the building regulations and the value of large scale system testing

- RIBA 2030 climate challenge: How steel building envelope solutions contribute

- Pre-finished steel standing seam systems for roof & wall cladding

- CDM regulations 2015 and their impact on steel building envelope specification.

- Steel building envelope systems for non-domestic buildings

- Steel for roof and wall cladding

EN-Construction-Product-Colorcoat Prisma-textured

EN-Construction-Product-Colorcoat Prisma Textured | Benefits

-

Revolutionary 3 layer coating technology, with an optimised thicker clearcoat to achieve a true textured effect.

-

The most matt option as part of the Colorcoat Prisma® range with gloss less than 5%.

-

Meets the highest European standards for corrosion and UV resistance (Ruv4 and RC5 as per EN 10169).

-

Robust and durable topcoat for easier handling and processing.

-

Confidex® Guaranteed for up to 40 years for the weatherside of the product when used for industrial and commercial buildings. Additionally the Confidex® Guarantee has no inspection or maintenance requirement to maintain its validity except when Colorcoat Prisma® is used on a roof or wall that has a Photovoltaic (PV) installation.

-

Optimised Galvalloy® metallic coating for ultimate corrosion resistance and cut edge protection.

-

Independently tested for liberation of volatile organic compounds (VOC) against EN ISO 16000-9 and achieved an A+ rating.

-

Fully REACH compliant & free of chromates including hexavalent chrome.

-

Made in the UK. Certified to BES 6001 Responsible Sourcing Standard.

If you have any questions or for further information click here to contact us.

EN-Construction-Product-Colorcoat Prisma Textured | Typical properties

| Properties | Test Standard | ||

|---|---|---|---|

| Nominal organic coating thickness Textured |

(μm)* |

70 |

EN 13523-1 |

| Specular gloss (60°): Textured |

(%) |

<5 |

EN 13523-2 |

| Scratch resistance: Textured |

(g) |

>3000 |

EN 13523-12 |

| Abrasion resistance (Taber, 250 rv, 2 kg): Textured |

(mg) |

<18 |

EN 13523-16 |

| Flexibility: Minimum bend radius Reverse impact Adhesion (Cross hatch) Pencil hardness |

(T) (J) (%) |

0.5T@16°C ≥18 100 H |

EN 13523-7 EN 13523-5 EN 13523-6 EN 13523-4 |

| Maximum continuous operating temperature |

(°C) | 90 | |

| Corrosion resistance: Salt spray Humidity |

(h) (h) |

1000 1500 |

EN 13523-8 EN 13523-26 |

| Corrosion resistance category |

RC5 CPI5 |

EN 10169 | |

| UV resistance category |

Ruv4 | EN 10169 |

*μm = micron

Notes

1. The figures contained in this table are typical properties and do not constitute a specification. Tested in accordance with EN 13523.

2. For health and safety datasheets contact the Colorcoat Connection® helpline.

If you have any questions or for further information click here to contact us.

EN-Construction-Product-Colorcoat Prisma Textured | Product performance

Galvalloy®

Colorcoat Prisma® uses the unique and proven Galvalloy® metallic coating by Tata Steel. Galvalloy® is made with a special mix of 95% Zinc (Zn) and 5% Aluminium (Al) that conforms to EN 10346:2015. The carefully developed proportions of Zinc and Aluminium in Galvalloy® offers a combination of increased barrier and sacrificial protection when compared with conventional Hot Dip Galv (HDG) coatings and provides unrivalled corrosion protection, even at the cut edges.

FIRE PERFORMANCE

Reaction to fire

Colorcoat Prisma® - Textured has been tested to EN 13823 and EN ISO 1716 and can be classified in accordance with EN 13501-1 as A2-s1, d0. This classification is valid for all gauges ≥ 0.47mm and for all colours in the product range for single sided product.

Performance of roof coverings

Colorcoat Prisma® - Textured is deemed to satisfy, without the need for further testing, the requirements for external fire performance of roof covering products in accordance with Commission Decision 2000/553/EC. This is valid for all gauges ≥ 0.4mm and for all colours in the product range for single sided product.

Colour consistency

If tonal consistency is critical, all cladding for a single elevation should come from the same production batch. All metallic shades exhibit a degree of directionality.

Matching components

If accessories made from other materials are to be colour-matched to the roof or wall cladding, the best reference is the actual profiles or panels delivered to site, or material from the same batch.

Metal hand samples

Metal hand samples are available for all colours. For a truer representation of colour and effect, please obtain metal hand samples.

If you have any questions or for further information click here to contact us.

EN-Construction-Product-Colorcoat Prisma Textured | Hand samples

Order samples via email for Colorcoat Prisma®

Our hand samples can assist in colour selection and finalising product specification. Metal hand samples are available for all colours. For a truer representation of colour and effect, please obtain metal hand samples.

You can order Colorcoat Prisma - Textured samples by contacting the Colorcoat Connection® helpline on +44 (0) 1244 892434, emailing colorcoat.connection@tatasteeleurope.com

If you have any questions or for further information click here to contact us.

EN-Construction-Product-Colorcoat Prisma | The Confidex® Guarantee

For over 25 years the Confidex® Guarantee from Tata Steel has remained best in class. Confidex® is the product performance guarantee for Colorcoat HPS200 Ultra® and Colorcoat Prisma®, when used in an external conventional building envelope application namely roof and wall cladding using single skin, built-up or composite panel construction in industrial and commercial buildings.

Confidex® offers the longest and most comprehensive guarantee for pre-finished steel in Europe.

If you have any questions or for further information click here to contact us.

EN-Construction-Product-Colorcoat HPS200 Ultra | Register the Confidex® Guarantee

Please complete the online form to register the Confidex® Guarantee for Colorcoat HPS200 Ultra® and Colorcoat Prisma®.

This form can be used to register the Confidex® Guarantee for Zone 1 and Zone 2.

Please click here to register for the Confidex® Guarantee

Transferring the Confidex® Guarantee

A registered Confidex® Guarantee is transferable in the event of sale or transfer of owner or tenant of a building. Please contact the Colorcoat Connection® helpline.

Note: Confidex® must be registered within 3 months of the building completion date for the guarantee to be valid.

If you have any questions or for further information click here to contact us.

EN-Construction-Product-Colorcoat Prisma | Sustainability

At Tata Steel we are committed to making the products society needs and to making them in the most responsible way. Our commitment to sustainability also means we actively manage our impacts and contribution throughout the full life of our products - with our suppliers, within our own operations, through the supply chains we serve and by taking responsibility for recycling steel. Colorcoat Prisma® has achieved BES 6001 responsible sourcing certificate which reinforces our commitment to sustainability.

Life Cycle Assessment

We constantly strive to ensure that the manufacturing processes and materials used to manufacture Colorcoat Prisma® are the most sustainable available. Moreover, the enhanced robustness and durability of Colorcoat Prisma® mean that it significantly outperforms other pre-finished steel in terms of environmental impacts over the full life cycle. To demonstrate the environmental impacts, Tata Steel have published an Environmental Product Declaration (EPD) for each of the Colorcoat® assessed cladding systems, based on an initial Life Cycle Analysis.

System environmental assessment

In the UK all roof and wall systems using pre-finished steel achieve a Green Guide A+ rating. Manufacture and processing of Colorcoat Prisma® into building envelope products, through our approved supply chain, can meet the responsible sourcing criteria for BREEAM. Our manufacturing site has an environmental management system which has been certified to ISO 14001.

Recycling

Colorcoat Prisma® is truly recyclable without any loss of quality, time after time. There is a well established and very efficient steel recycling infrastructure which ensures that all steel collected at end of life goes back into steel manufacture. Through this efficient recycling of steel, the environmental investment in steel-making is never wasted, making steel the most sustainable construction material.

If you have any questions or for further information click here to contact us.

EN-Construction-Product-Colorcoat Prisma Textured-downloads

Product Downloads

EN-Construction-Datasheet-Colorcoat Prisma Textured Datasheet

Colorcoat Prisma® - Textured datasheet

EN-Construction-Approval_or_Certificate-Colorcoat Prisma BBA certificate

Colorcoat Prisma BBA certificate

EN-Construction-Site_instruction-Colorcoat Inspection and maintenance manual

Colorcoat® Inspection and maintenance manual

EN-Construction-Approval_or_Certificate-Colorcoat Prisma® Ruv4 certificate

Colorcoat Prisma® Ruv4 certificate

EN-Construction-Approval_or_Certificate-Colorcoat Prisma Textured Sargasso certificate

Colorcoat Prisma® - Textured Sargasso RC5 certificate

EN-Construction-Site_instruction-Colorcoat PV Installation Guidelines

Colorcoat® PV Installation Guidelines

EN-Construction-Certificate-BES 6001-Colorcoat

BES 6001 Certificate - Colorcoat products

EN-Construction-Book a CPD

We offer a range of face to face and online CPDs aimed at Engineers and Architects

These free seminars can be booked at any time between 9am and 5pm. Our online webinars can all be delivered via Skype for Business and Teams, but we can consider other platforms if this will not work for your practice.

Below outline the CPDs we have available - Book yours today

- Decarbonising your structural hollow section designs

- Essentials of Structural Hollow Sections

- Welded Joints in Tubular Steelwork - Eurocode 3 Part 1-8

- Concrete Filled Hollow Sections - Composite Design – Eurocode 4

- Composite Floor Deck in Construction

- Structural Roof Deck in Construction

- Specifying metal clad envelope systems in accordance with ADB2 of the building regulations and the value of large scale system testing

- RIBA 2030 climate challenge: How steel building envelope solutions contribute

- Pre-finished steel standing seam systems for roof & wall cladding

- CDM regulations 2015 and their impact on steel building envelope specification.

- Steel building envelope systems for non-domestic buildings

- Steel for roof and wall cladding

EN-Construction-CaseStudy-Residential-Nordic Haven

Overlooking the River Brda in the Polish city of Bydgoszcz, Nordic Haven is a stunning 16-storey mixed-use structure, containing both office and residential elements.

The building has cascading terraces that climb upwards, offering most floors uninterrupted views over the adjacent Brda River. On one side of the development, the building tops out at only four-storeys, in order to match an existing neighbouring structure. On the other elevations, Nordic Haven climbs up in terraces to its maximum 16-storeys height.

The apartment residents enjoy raised courtyards with greenery and viewing platforms, as well as green terraces on the roofs.

Colorcoat Prisma® pre-finished steel from Tata Steel has allowed the developers of this unique building to create a modern and standout landmark complex.

EN-Construction-CaseStudy-Commercial-Skanska Wave New

The three cities of Gdansk, Gdynia and Sopot, located along the Baltic coast, are inter-connected and form a metropolitan area known as Tri-City or The Triple City. One of the projects ear-marked for this dynamically developing office district in Gdansk is Skanska’s WAVE, a complex of two office buildings, the first of which was completed early June 2020.

Gdansk is one of the most popular destinations in Poland, and part of the rapidly developing Tri-City business area. The eye-catching WAVE is the first of two office buildings planned for this prominent site on Grunwaldzka Avenue in Oliwa, and its construction will contribute to growth in this area. Designed by Medusa Group, the design combines a timeless, industrial architecture with public meeting places that was inspired by the Baltic coast.

EN-Construction-CaseStudy-Commercial-Tiger Trailers

Trailer and commercial vehicle body manufacturer, Tiger Trailers, has relocated to a new £22M manufacturing facility in Winsford, Cheshire. Design and construction of the new facility, which incorporates a host of energy-efficient systems, was completed in just 12 months.

The construction of the facility has utilised Tata Steel’s Colorcoat® pre-finished steel for the cladding, to create a modern

complex.

The bespoke production and office complex is located on a 20-acre site and includes 15,600m2 of state-of-the-art chassis fabrication, body assembly, paint and final finish facilities.