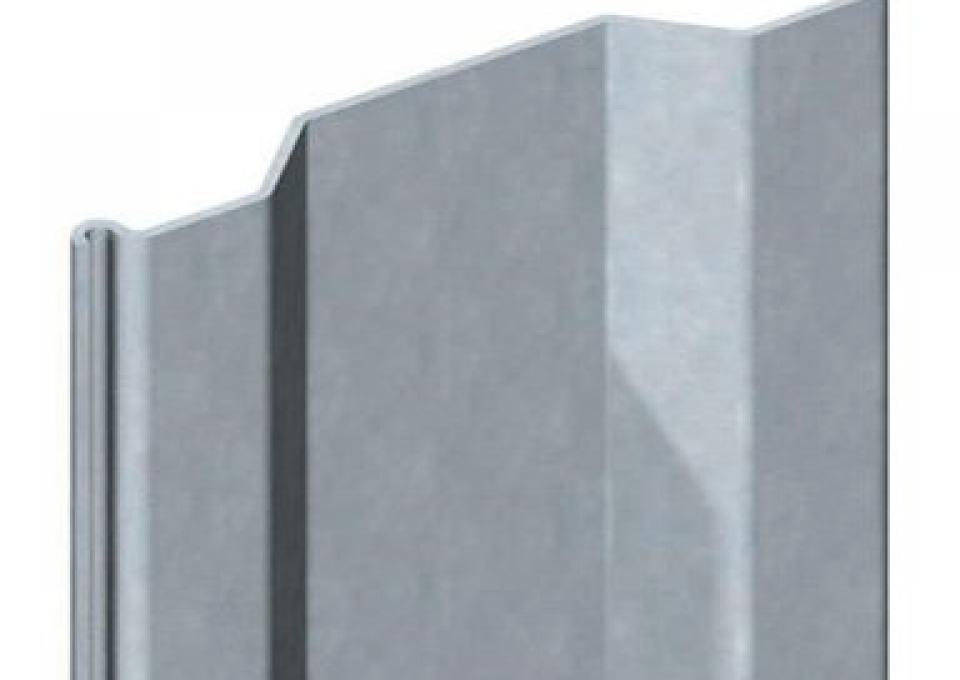

Trench sheeting

Robust solution for both temporary and permanent use.

Tata Steel are a leading manufacturer of trench sheeting in the UK, with a product range that has been developed as a robust solution for both temporary and permanent use as a support to earth banks, waterway banks and service trenches.

EN-Construction-Product-Trench sheeting-default

EN-Construction-Product-Trench sheeting | Overview

Trench sheets can be used to support earth banks for the safety of construction workers, and are ideal for permanent reinforcement of waterway banks and service trenches.

The strength, speed and flexibility of light sheet piles makes it ideal for all forms of temporary and permanent works, the durability and ease of extraction means that light sheet piling can be re-used in sustainable construction. In many cases, however, the use of a steel trench sheet structure can actually eliminate the need for temporary works with the trench sheet performing the permanent function concerned e.g. canals, basement walls.

Tata Steel has over 50 years experience in the design and manufacture of cold formed steel. We offer customers a quality product, value-engineered to suit a range of applications at an affordable price. Our product range has been developed as a robust solution for temporary and permanent use. We offer comprehensive sales and technical support throughout all aspects of trench sheeting from design, manufacture and supply.

EN-Construction-Product-Trench sheeting | Product range

Tata Steel operate a number of roll-forming machines that transform flat material, via a series of rollers, into a given section. With an extensive range of in-house roll sets, Tata Steel can offer a full scope of widths, steel gauge, and lengths tailored to individual needs.

| Width (mm) | Depth (mm) | Thickness (mm) | Modulus (cm3/m) | Moment of Inertia (cm4/m) | Weight (kg/m2) | |

|---|---|---|---|---|---|---|

| Standard Lap | 330 | 35 | 3.4 | 48.3 | 81.7 | 32.9 |

| Standard Lap | 330 | 36.6 | 5 | 71.2 | 119.7 | 47.7 |

| L8 | 432 | 35 | 3.4 | 51.5 | 84.9 | 33.6 |

Trench sheet thickness

Various gauges are available in each profile to allow for individual ground conditions and corrosion possibilities.

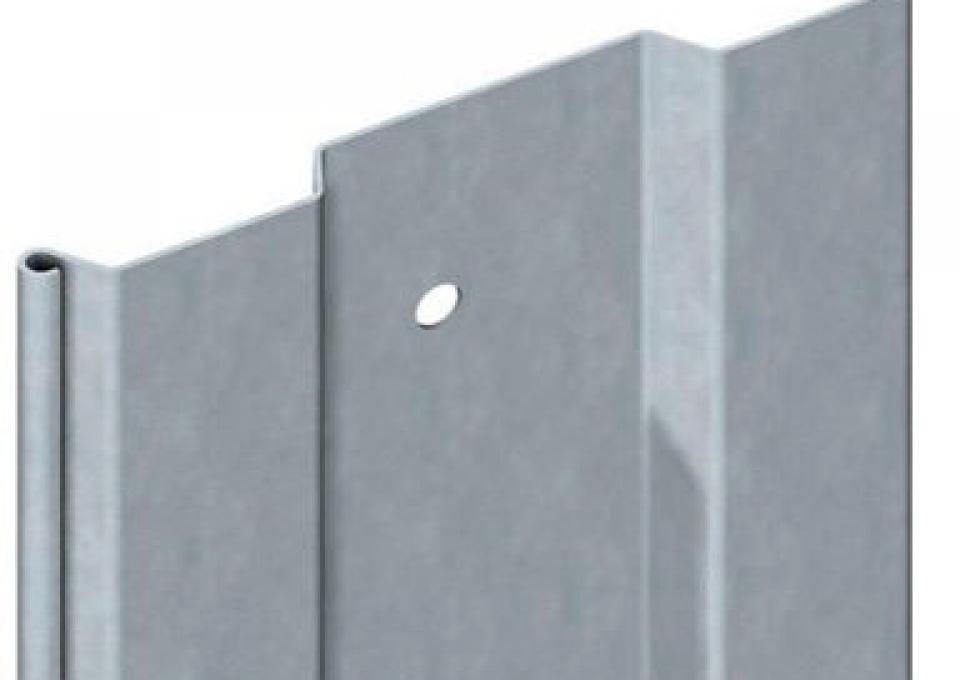

Corner Design

Corners can be manufactured to specific designs on selected profiles to meet the requirements of specific applications.

Sheet length

Sheets can be produced in lengths from 1-12m to suit your requirement. A high strength to weight ratio means that longer lengths can be expertly driven into place with minimal risk of damage whilst using conventional equipment. Our product range has been designed to encourage simple extraction, allowing effortless removal of the complete element through a hole positioned at the top of each sheet.

Finish

The life span of trench sheeting can fluctuate in accordance with its working environment. Several elements need to be considered including the degree of corrosion and whether additional weather protection is required. Working conditions can vary even within a single installation. Tata Steel recommend that customer’s installing trench sheeting within corrosive environments enhance the product performance to suit each application. We offer a hot dip galvanised finish to BS EN ISO 1461 on all trench sheeting.

EN-Construction-Product-Trench sheeting | Accessories

Accessories

<p>Alongside the main profiles is a wide range of accessories available to offer a complete solution.</p> <p><strong>Anchor Pile - </strong>a small pile connected to a structure by one tie to furnish lateral support.</p> <p><strong>Waling Bar - </strong>used to provide additional strength.</p> <p><strong>Tie Bar, Waling Bolt - </strong>used to connect the trench sheet to the anchor pile.</p> <p><strong>Trench Trough - </strong>bolted below the waterline, allowing aquatic plants to flourish without causing maintenance problems.</p> <p><strong>Driving Cap - </strong>used to significantly reduce excessive damage for all types of trench sheets during installation.</p>

EN-Construction-Product-Trench sheeting | FAQs

Q: Do you supply accessories?

A: Yes, we supply accessories for L8 trench sheets - waling bars/tie bars 1.8 or 2.4m/anchor piles and waling bolts. We can also supply tie bar extensions and tie bar connectors

Q: Is there a calculation to work out the number of accessories required?

A: We advise the British Waterways working practices

Q: How do you work out the number of sheets required from the wall length in linear metres (LM)?

A: The number of sheets required is determined by dividing the LM by the effective width of the sheet (Lap = 0.33m L8 = 0.432m)

Q: Can the sheets be coated?

A: All our sheets can be supplied as ungalvanised or galvanised.

Q: In what cases can standard lap sheets be used?

A: Standard lap sheets are used for lightweight piling. Lap sheets are generally used for those working in trenches. Other usages - basements, sewerage.

Q: In what cases can L8 sheets be used?

A: L8 sheets are generally used in canals, riverbanks and marinas.

EN-Construction-Contact-Tubes-Highway Engineering-Parapets-Llanwern

Call our hotline

Llanwern Works

Newport

South Wales

NP19 4QZ

United Kingdom