Simpler supply chain

Protact® polymer-coated steel removes up to five non-core, cost-intensive unit operations associated with the use of lacquers and tinplate. This means you can simplify your supply chain and eliminate stockholdings – allowing you to focus on your core business.

Higher efficiency

Protact allows simplified and shorter canmaking lines on a smaller physical footprint. Leaner, more efficient canmaking means you can scale up manufacture economically. Protact’s extra width – up to 1220mm – can help you to maximise yield.

More sustainable

With Protact, there is no emission of volatile organic compounds (VOCs) during canmaking. By dispensing with lacquer-related operations, your canmaking process consumes less energy and water. Protact is infinitely recyclable with no loss of quality.

Protact laminated steel from Tata Steel meets market needs for more sustainable, reliable and safe packaging material. Infinitely recyclable, Protact is food-safe and optimised for efficient canmaking. It is a proven material solution across a number of high-performance canmaking applications and formats including DRD cans and D&I aerosols.

Efficient canmaking

Protact removes the need for up to five cost-intensive operations associated with the use of lacquers – eliminating VOC emissions and cutting water and energy consumption. Its extra width allows a 10-15% increase in canmaking output. High wall ironing ratios deliver consistently reliable forming.

Optimised performance

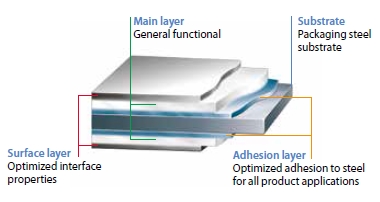

Protact is suitable for all product applications. It comprises a steel substrate with a three-layer polymer coating system on each side. Each layer is optimised for can performance and processing benefits. The coating can be tailored to your needs for maximised efficiency and brand impact.

Secure supply

We have been supplying Protact into the market for more than 20 years. Continuing investment in multiple, high-capacity production lines means we offer security of supply – so you can be confident of maintaining high volume production.

Customer support

We are the only steelmaker with commercial canmaking equipment as part of our world-class Research & Development facilities. Our experts can help you to optimise your canmaking line through using Protact. To help you outperform the competition, we can also support you in the development of new can formats.

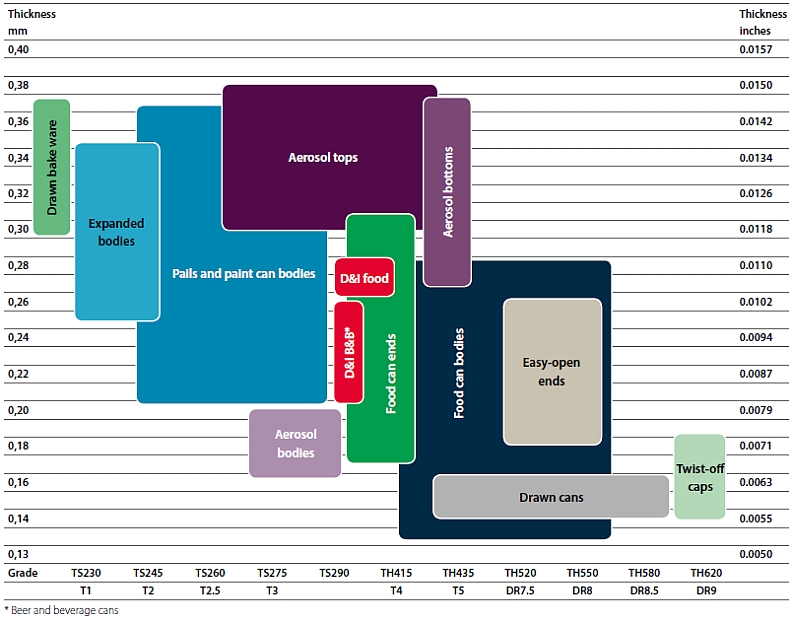

General specification window for packaging applications:

EN-Packaging-Brochure-Protact

Protact® brochure

EN-Packaging-Datasheet-Protact

Protact® datasheet

EN-Packaging-CaseStudy-Protact system change TSE

Protact® system change case study

EN-Packaging-Datasheet-Protact food safety

Protact® food safety datasheet

EN-Packaging-Datasheet-Protact 3-piece cans

Protact® 3-piece cans datasheet

Protact laminated steel is a fully approved and controlled food-safe product. For 2-piece D&I food can production, Protact offers significant benefits including opportunities to increase yield and cut costs. Protact’s performance in DRD fish cans has been proven over many years.

We can customise Protact to meet your specific applications and canmaking needs. Continuing investment in multiple, high-capacity production lines means we offer security of supply – so you can be confident of maintaining high volume production.

Food-safe packaging

Protact is BPA-free and fully compliant with all relevant European and USA food contact legislation. Well-controlled purity levels of all chemical substances used in Protact also enable compliance to upcoming legislation on non-intentionally added substances (NIAS). Certification and compliance of Protact is undertaken by the independent and respected European research institute, TNO Triskelion.

Efficient canmaking

By removing the need for lacquer-related operations, Protact offers canmakers the opportunity to increase yield and become more competitive. In 2-piece D&I canmaking, up to five cost-intensive operations can be removed. A leaner line means you can scale up manufacturing to meet market demand. To deliver further gains, we are developing Protact to full D&I width – 1220mm – for optimised can line output.

Optimised performance

Protact comprises a steel substrate with a three-layer polymer coating system on each side. For food applications, the three layers have been optimised for a variety of performance and processing demands. Protact’s adhesion layer is optimised for sterilisation. Its main layer is optimised for non-blushing performance and/or coating colour. The surface layer of Protact has been specially developed for content release and forming performance. The internal and external coating systems do not crack or perforate during the D&I process – allowing wall ironing reductions of 50 – 55%. The unique build-up of Protact’s coating layers delivers a non-abrasive material – minimising tool wear during canmaking.

Ideal for fish cans

Protact offers a robust material that meets the demands of fish packaging. Protact has a long history of use in 2-piece DRD cans for the USA salmon market and South American seafood market. Protact’s inert three-layer polymer coating system has excellent organoleptic properties –ensuring the original taste of the packaged food is not affected. Combined with its low level of porosity, this makes Protact the ideal solution for contents packed in oil and brine. For fish cans, Protact’s coating system is optimised for maintaining content appearance and for easy content release.

EN-Packaging-Brochure-Protact

Protact® brochure

EN-Packaging-Datasheet-Protact

Protact® datasheet

EN-Packaging-Datasheet-Protact food safety

Protact® food safety datasheet

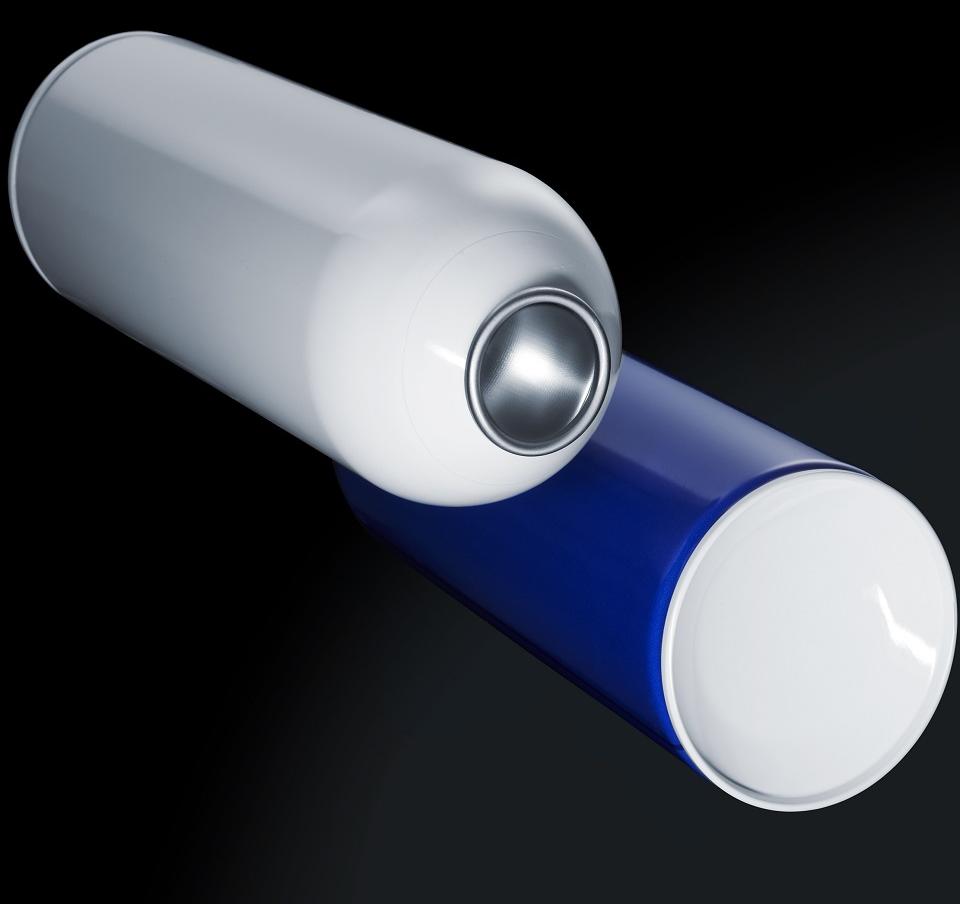

Proven in commercial production of D&I aerosol cans, Protact laminated steel offers several advantages over lacquered aerosol components. Protact’s external surface is optimised for print – for improved branding performance. Its unique polymer coating system means it is highly formable, with no loss of containment performance. Excellent corrosion-resistance removes the risk of rust rings.

We can customise Protact to meet your specific applications and processing needs. With commercial canmaking equipment as part of our world-class Research & Development facilities, our experts can also help you to deliver new formats.

Brand differentiation

Highly formable, Protact can help you to provide more aesthetically enhanced shapes and formats. This gives you the opportunity to produce a market-differentiating aerosol that competes with the aluminium monoblock. Because Protact’s three-layer polymer coating system does not crack or perforate during forming, it also ensures reliable containment performance. For aerosol manufacture, we have optimised Protact to support high-quality print and improved branding performance. Protact is designed to work with the latest direct-to-cylinder printing – helping you to stay ahead in image quality, productivity and reliability.

Optimised performance

Protact offers proven product contact performance for aerosol contents. It comprises a steel substrate with a three-layer polymer coating system on each side. For aerosol applications, these layers have each been optimised for a variety of performance and processing demands. The main layer is optimised for barrier properties and/or coating properties, the adhesion layer is optimised for heat resistance and the surface layer for print. The flexible, non-brittle nature of the coating system means it is not susceptible to chipping. This ensures excellent anti-corrosion performance – eliminating the risk of rust rings in humid environments.

Efficient aerosol manufacture

Protact removes the need for cost-intensive unit operations related to the use of lacquers and tinplate. As a result, canmakers have an opportunity to increase yield and become more competitive. A leaner line means you can focus on your core business – growing it more economically and widening your product portfolio.

EN-Packaging-Brochure-Protact

Protact® brochure

EN-Packaging-Datasheet-Protact

Protact® datasheet

EN-Packaging-CaseStudy-Protact system change TSE

Protact® system change case study

Protact laminated steel is well-suited to general line applications. Its performance in paint cans has been proven over nearly two decades. Protact offers reliable formability and pack performance. It is available in a choice of grades and can be customised to suit your application and canmaking needs.

Meeting market needs

In the coatings market, the move from solvent-based to water-based paint systems demands packaging material with reliable corrosion resistance. Protact laminated steel, with its three-layer polymer coating system, meets this demand. The non-brittle, flexible coating is not prone to chipping – making it the ideal choice for formation of lids, rings and bottoms. For general line applications, Protact’s adhesion layer is optimised for chemical resistance. Its main coating layer is optimised for barrier properties and/or can coating colour.

Efficient canmaking

Protact removes the need for cost-intensive unit operations related to the use of lacquers and tinplate. As a result, canmakers have an opportunity to increase yield and become more competitive. A leaner line means you can focus on your core business – growing it more economically and widening your product portfolio.

EN-Packaging-Brochure-Protact

Protact® brochure

EN-Packaging-Datasheet-Protact

Protact® datasheet

EN-Packaging-CaseStudy-Protact system change TSE

Protact® system change case study

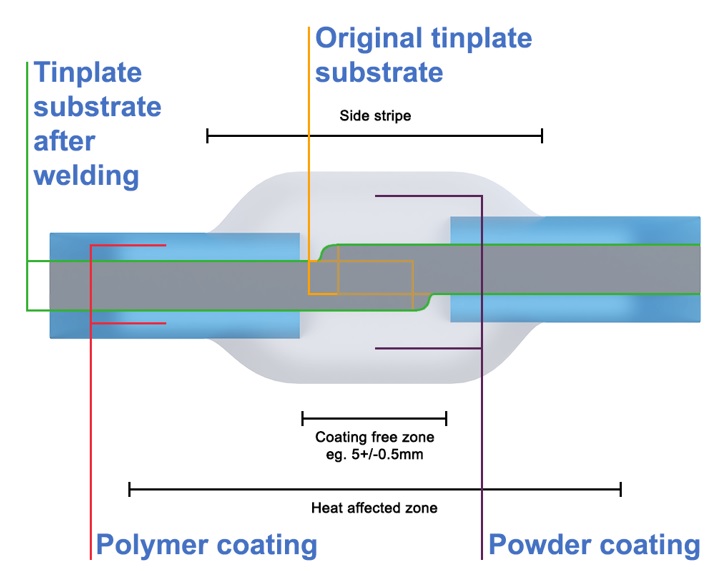

Already a proven material solution in 2-piece canmaking, we have now developed Protact to meet the needs of 3-piece canmakers. The material’s coating-free zones are tailored to enable welding of the required can diameter and height. It removes the need for cost-intensive lacquering on the internal side of the can material and if present the external side. This frees up capacity and simplifies 3-piece canmaking operations.

Protact for 3-piece cans offers good side stripe adhesion performance. It is suitable for all 3-piece canmaking operations including welding, flanging, beading and double seaming.

Product features

Protact for 3-piece cans comprises:

- a tinplate substrate – delivering the required elongation properties for successful welding, flanging, beading and seaming

- a three-layer polymer coating system- can be applied on each side of the substrate or on one side only. The coating system is optimised for food, aerosol, beer and beverage, and general line product applications

- polymer coating-free zones – customised to can diameter requirements for H-grain welding, resulting in a coating that does not shrink or delaminate during welding, side strip curing and can be sterilised.

Can making

The coating-free zones in Protact for 3-piece cans allow for H-grain welding. The position and width of the zones can be varied to accommodate all standard can and aerosol diameter requirements from 45 mm and up. The consistent width and position of the coating-free zone and close control of tolerances enable stable and efficient welding operations. Side striping can be applied with good adhesion.

The choice of substrate ensures the required elongation properties for successful flanging and double seaming. Protact’s optimised polymer coating system is entirely compatible with these operations and its performance levels remain intact. Protact for 3-piece food cans is suitable for beading.

Dimensions

Protact for 3-piece cans is available in a range of widths up to 1058 mm and in a thickness range of 0.15 mm to 0.60 mm. Welding margins can be created to produce cans from a diameter 45 mm and upwards. Obviously the layout is determined by your requirements. Ongoing product development is extending the choice of dimensions. Please contact us to discuss your needs.

Product support

Our material experts and customer technical support are available to support the deployment of our products in your individual can format and product application. This includes support for adoption of H-grain welding to realise the benefits offered by Protact for 3-piece cans.

EN-Packaging-Brochure-Protact

Protact® brochure

EN-Packaging-Datasheet-Protact

Protact® datasheet

EN-Packaging-Datasheet-Protact 3-piece cans

Protact® 3-piece cans datasheet

Applications