Catnic® Urban (formally Colorcoat Urban)

Rigorously tested to guarantee performance in different conditions

Catnic® Urban Standing Seam steel roof and wall cladding systems are a lightweight, strong and versatile alternative to traditional building materials.

Seven times lighter than standard roof tiles Catnic® Urban is a great choice for new build, refurbishment or extensions. There is no limit to the variety of shapes and forms that can be achieved, all designed meticulously to help you create a stunning exterior or roof, whether you are looking to stand out from the crowd, blend seamlessly in with your surroundings or transform your existing build into something more modern.

EN-Construction-Product-Catnic Urban-default

EN-Construction-Product-Catnic Urban | Overview

Made in the UK

Manufactured in Shotton, North Wales, Catnic® Urban is manufactured using the renowned Colorcoat Prisma® or Colorcoat HPS200 Ultra® pre-finished steel from Tata Steel, favoured by self-builders and developers for the stunning aesthetic finish they provide, with contemporary colours suited to both urban and rural homes. Quick build times are possible with neat crisp finishes to complete design and build choices.

Product benefits:

- Quick fit system with invisible fixings, reduces installation time on site compared with traditional roofing products.

- Can be installed on a roof with a pitch as low as 5 degrees.

- Seven times lighter than traditional roof tiles.

- Available in a range of colours designed to blend with the landscape, including colour matched gutters and fascias.

- Robust Confidex® Home Guarantee for 25 years upon registration.

- Low maintenance.

- BRE Green Guide A+ rated product, and 100% recyclable at end of life.

- Backed by independent testing and BBA certification.

- Has a Class AA /B roof (t4) performance rating according to BS 476 Part 3 / EN1187 and meets all UK roofing application requirements.

If you have any questions or for further information click here to contact us.

EN-Construction-Product-Catnic Urban | Dimensions

| Mono pitch roof (free standing) | Duo ridge | Lean-to (extension) | |

|---|---|---|---|

| Panel width | 514mm and 305mm | 514mm and 305mm | 514mm and 305mm |

| Panel height | 25mm | 25mm | 25mm |

| Panel length | 2 - 12.5m | 2 - 12.5m | 2 - 12.5m |

| Panel gauge | Urban Seam® 0.7mm nominal | Urban Seam® 0.7mm nominal | Urban Seam® 0.7mm nominal |

| Specification | 514mm most roof applications. 305mm better resistance to wind uplift. |

514mm most roof applications. 305mm better resistance to wind uplift. |

514mm most roof applications. 305mm better resistance to wind uplift. |

| Joining detail | Available for rafter lengths over 12.5m | Available for rafter lengths over 12.5m | Available for rafter lengths over 12.5m |

| Fixings | Secret-fix | Secret-fix | Secret-fix |

| Eave detail | Creates a sharp edge. Provides a drip for rainwater run-off. |

Creates a sharp edge. Provides a drip for rainwater run-off. |

Creates a sharp edge. Provides a drip for rainwater run-off. |

| Verge | Roof side. Overhangs outside face of wall. Creates drip and nice finish. |

Roof side. Overhangs outside face of wall. Creates drip and nice finish. |

Roof side. Overhangs outside face of wall. Creates drip and nice finish. |

| Ridge profile | Mono ridge | Standard Duo and Large Duo | Top abutment |

| End caps | Left and right hand | Standard Duo and Large Duo | Bespoke |

| Backing plate | Mono ridge backing plate | Clips onto Z bars | Fixed to structurally sound exterior wall |

| Ventilated | Available on request | Available on request | Available on request |

If you have any questions or for further information click here to contact us.

EN-Construction-Product-Catnic Urban | Testing and performance

Catnic® Urban comes with third party validation to the highest standards on quality, product performance, fire safety, and environmental credentials.

| Characteristic | Performance |

|---|---|

| Yield strength | 0.7mm sheet - 220 kN/mm2 |

| Tensile strength | 0.7mm sheet - 300 kN/mm2 |

| Elognation | 0.7mm sheet - 20% |

| Water permeability | Impermeable |

| Dimensional change | 12 x 10-6 k-1 |

| Water vapour and air permeability | Impermeable |

| Release of dangerous substances | Not classified as dangerous |

| Durability | Coating S220 + ZA255 |

- Backed by independent testing and BBA certification. Download our roof and wall panel certificate from our product downloads.

- Rigorous testing in different conditions gives confidence in durability

- Certified ‘Very Good’ to BREs BES 6001 responsible sourcing standard

- When used as part of a roof cladding system, can achieve a Class AA performance rating when tested to BS476 Part 3 1958

If you have any questions or for further information click here to contact us.

EN-Construction-Product-Catnic Urban | Technical

The Urban Seam® panel is a fully supported roof panel, comprising an outer skin profiled from 0.7mm thick, galvalloy treated, grade S220GD steel sheets to BS EN 10346: 2009. The sheet is treated with a 200 micron coating on the exposed face and a 10 micron polyester coating on the reverse face.

Wind Uplift deflection values

Specification of the 305mm/514mm wide panel is dependant on location, wall height, storey height and roof pitch. A structural engineer should complete a wind uplift calculation for your specific area before making any final decision. Please note the table below is for guidance only:

| Roof pitch (degree) and wall | No. storeys | Wind speed V2 | Panel width 305mm | Panel width 514mm |

|---|---|---|---|---|

| (5-9) | <3 | ≥25 | Y | N |

| (5-9) | 4 - 6 | ≥25 | Y | N |

| (5-9) | <3 | <25 | Y | Y |

| (5-9) | 4 - 6 | <25 | Y | N |

| (≥10) | <3 | ≥25 | Y | Y |

| (≥10) | 4 - 6 | ≥25 | Y | N |

| (≥10) | <3 | <25 | Y | Y |

| (≥10) | 4 - 6 | <25 | Y | Y |

Load Span Tables

All load span calculations should be calculated by a structural engineer for the project. All load span information is based on the boarded structure on standard 600mm or 400mm centres a structural engineer should be consulted for any further information.

Uplift wind deflection values (KN/m²)

| 10mm deflection | 20mm deflection | |

|---|---|---|

| 305mm | 3.49 | 6.98 |

| 514mm | 0.73 | 1.46 |

Build-up examples

Urban Seam® profile is fixed to 18 mm Ply or OSB 3 board, with a separating layer of breathable membrane (15 mm board is used for SIP panels). For other board types and dimensions please contact Catnic® Urban. Below this, warm roof and cold roof build-ups can be accommodated. More comprehensive detailed advice on this is available from the Catnic® Urban team.

DoP

Under the CPR, all products used in construction must now have CE Marking. This provides clear indication that it meets the requirements of the relevant harmonised standard, and has been approved by a Notified Body to apply the CE Mark. The Urban Seam® Declaration of Performance provides information on the essential characteristics of the Urban Seam® profile and that it conforms to its declaration.

Condensation risk

In common with all metal roof constructions, there is a risk of condensation. This can arise as either interstitial condensation within the roof construction or surface condensation at thermal bridges.

To prevent condensation forming between the metal sheets and the substrate, measures should be taken to minimise water vapour reaching the OSB board by incorporating:

- Vapour control layer in the roof construction and providing an adequate seal around ceiling.

- Breather membrane in the roof construction to allow the air to circulate freely.

- Adequate insulation level meeting current U-values.

Resistance to soft and hard body impact: In accordance with MOAT 43: UEAtc Directives for impact testing opaque vertical building components. Part 2.2.1: Impact from large soft bodies and MOAT 43: UEAtc Directives for impact testing opaque vertical building components. Part 2.2.2: Hard body impacts.

In a roof and wall installation, the panel will have adequate resistance against hard and soft body impact in combination with the standard wood board build up.

Sound and Noise

The Catnic® Urban standing seam roof requires a substrate Ply or OSB 3 board or SIP panel, and is no noisier than standard slate, concrete or clay tile. In many cases the transfer of airborne noise is less than alternative materials.

Sound levels or loudness are expressed in decibels (dB). The decibel rating is a representation of the intensity or volume of the sound. The intensity of the sound depends on the pressure level and can be accurately quantified by a sound level meter.

When considering the acoustic performance requirements of a building there are a number of criteria to consider which include airborne noise; impact noise; internal noise reverberation; and flanking.

Fire

Catnic® Urban is tested against all the required fire tests. It carries a ‘low risk’ classification and meets Class 0 requirement as defined in the Building Regulations for the UK. When used as part of a roof cladding system, the Catnic® Urban seam can achieve a Class AA performance rating when tested to BS 476 Part 3: 1958.

The performance of a building in a potential fire situation must be seen as a fundamental requirement and it is essential that this be considered at the initial design stage. Compliance with the Building Regulations is a major consideration for fire performance:

The focus is specifically on the building envelope and understanding how to satisfy these requirements when using Catnic® Urban Seam wall and roof cladding system. While the choice of building envelope materials is of key importance, it should be seen as part of an overall strategy of compliance and risk management. Where risks are high or difficult to control, more emphasis needs to be placed on the intrinsic performance of the building components.

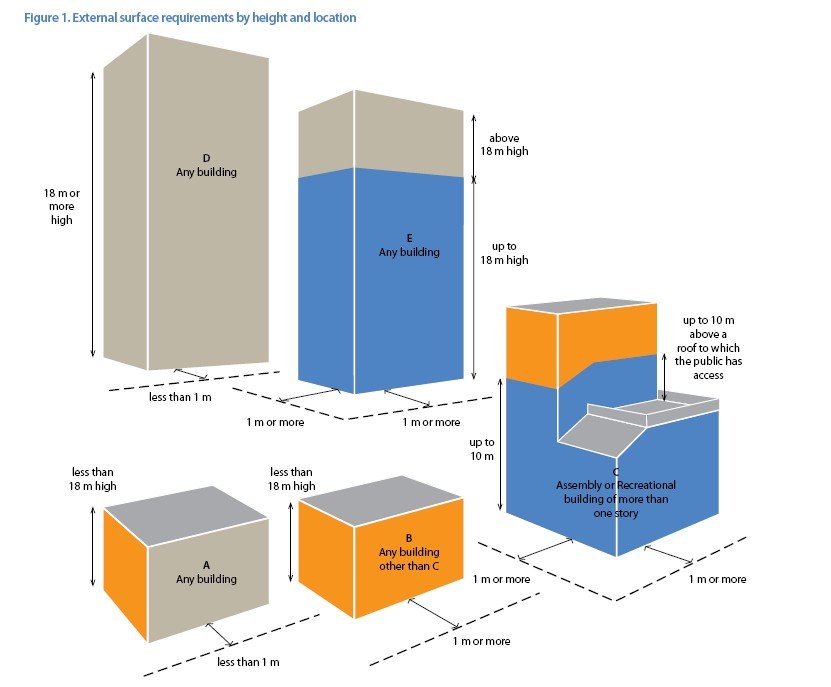

Provisions for external surfaces of walls: Approved Document B1 specifies the performance requirements for the external surface of walls according to building height and location.

Figure 1 summarises these requirements for a range of building types and locations.

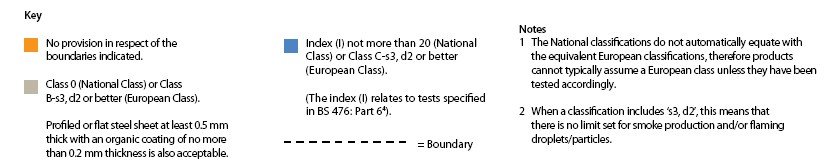

Approved Document B1 specifies the performance requirements for external roof coverings according to location in relation to the distance of the building from a relevant boundary. Figure 2 sets out the minimum requirements that are stated according to European EN 11875 and National BS 476 – 33.

Figure 2. Performance requirements for roof coverings

There are no restrictions on the use of roof coverings that are designated AA, AB or AC, National Class, or B ROOF (t4), European class. Roof products which meet the requirements stipulated in Commission Decision 2000/553/EC can be considered to satisfy the requirements without the need for testing.

Catnic® Urban roof and wall cladding systems meet all the requirements for all external roof and wall coverings.

If you have any questions or for further information click here to contact us.

EN-Construction-Product-Catnic Urban fascia | Design details

Looking for help and advice with your designs?

The Catnic® Urban team of experts is available to offer the support you need and provide you with more detailed information on any of our Catnic® Urban range of products.

Whether you are looking for a more detailed drawing or a copy of our Specification guide contact the team (details below)

Duo ridge

Catnic® Urban duo ridge roof is one of the most popular designs ideal for traditional domestic buildings. The duo ridge design slopes in two different directions down from the ridge, and can be designed to suit your required style or shape.

Mono ridge

Catnic® Urban mono ridge roof is a single sloping free-standing surface. The mono ridge design slopes in one direction down from the ridge. It is both modern and contemporary and offers the perfect solution for new builds or additions to existing roofs.

Lean-to

Catnic® Urban lean-to roofs are fixed to an exterior wall of the building, providing small ground floor extensions and additional covered roofing space. The lean-to design is a simple, traditional concept which can be built entirely to suit you, as part of a new build or an extension to an existing structure.

Dormer

Catnic® Urban dormer roofs can be created with pitches as low as 5 degrees. Urban Seam® dormers can be designed for inclusion at construction stage or as a later addition to your build. Available to suit a wide range of shapes and sizes to suit pitched, flat or even the most difficult of dormer shapes. So versatile is the dormer that it is easily integrated with existing tiled roofs.

If you have any questions or for further information click here to contact us.

EN-Construction-Product-Catnic Urban | Confidex® Home Guarantee

As the systems continue to increase in popularity, Tata Steel has launched the Confidex® Home Guarantee for the UK and Ireland – which is valid for 25 years to provide homeowners with assurance of the building material’s performance used in the Catnic® Urban standing seam system.

Exposure to sunlight, extreme weather or coastal environments are all critical external factors that roofs and walls have to resist to maintain performance over time. Tata Steel is so confident in the performance of Colorcoat Prisma® and Colorcoat HPS200 Ultra® based on extensive testing of both products in laboratories and weathering sites around the world, that is offered irrespective of where the material is installed (roof or walls) or where the home is situated.

This means that those who choose to build their new home in a rural or coastal location are still eligible for the 25-year guarantee. This is a significant inclusion, for often the length or assurance of a guarantee will differ depending on the environment in which the product is located – a true testament to the performance of Tata Steel’s pre-finished steel.

If you have any questions or for further information click here to contact us.

EN-Construction-Product-Catnic Urban fascia | Hand samples

Our hand samples can assist in colour selection and finalising product specification.

Order samples online for Catnic® Urban:

Click here to choose your Catnic® Urban colour samples.

Alternatively, contact the Catnic® Urban team on +44 (0) 1244 892449.

If you have any questions or for further information click here to contact us.

EN-Construction-Product-Catnic Urban-downloads

Download our Catnic® Urban literature below

EN-Construction-Brochure-Colorcoat Urban Specification Guide

Colorcoat Urban® (now Catnic® Urban) Specification Guide

EN-Construction-Design_guide-Colorcoat Urban Installation Guide

Colorcoat Urban® (now Catnic® Urban) Installation Guide

EN-Construction-Approval_or_Certificate-BBA Certificate for Colorcoat Urban Roof panel

BBA Certificate for Colorcoat Urban® (now Catnic® Urban) Roof panel

EN-Construction-Approval_or_Certificate-BBA Certificate for colorcoat Urban Wall panel

BBA Certificate for Colorcoat Urban® (now Catnic® Urban) Wall panel

EN-Construction-Contact-Urban

Call the Catnic® Urban team

Tata Steel

Shotton Works

Deeside Flintshire CH5 2NH

United Kingdom