Trisofix™ universal mounting system

Trisofix™ a simple to use patented universal mounting system. Combined with pre-finished panels and products it creates a true DfMA solution that unlocks both off-site and on-site productivity.

Trisofix™ enables lower carbon, cost and time certain project delivery.

Made using high grade coated steel components the Trisofix™ mounting system fixes back to any structural wall type and can be used throughout a building, both for façades and internal fit out.

EN-Construction-Product-Trisofix-universal-mounting-system

EN-Construction-Product-Trisofix-Overview

Made using high quality coated steel components, the Trisofix™ mounting system fixes back to any structural wall type and can be used throughout a building, both for façades and internal fit out.

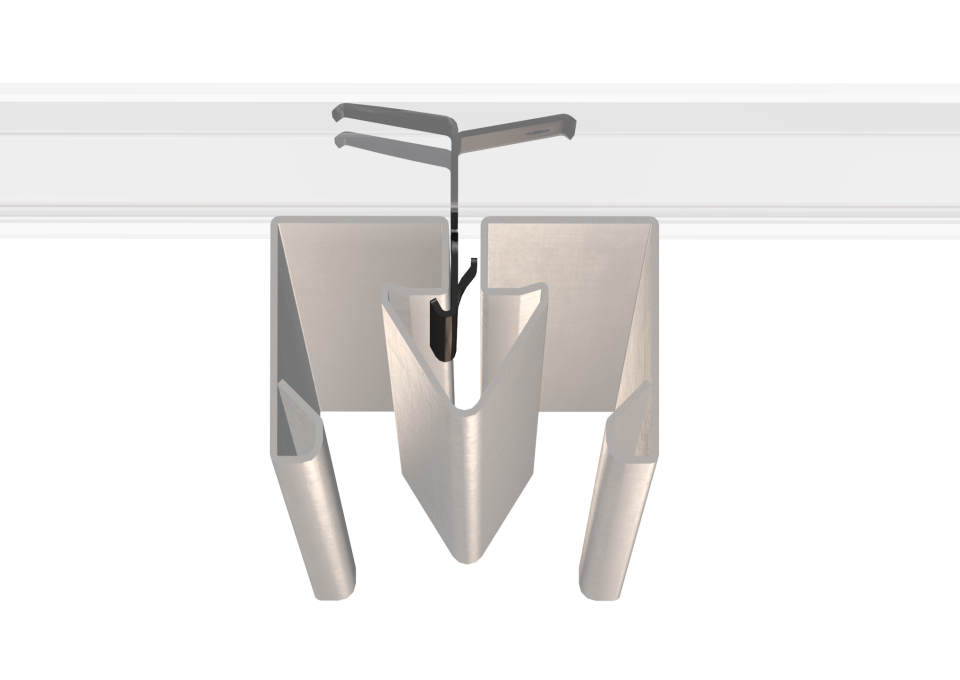

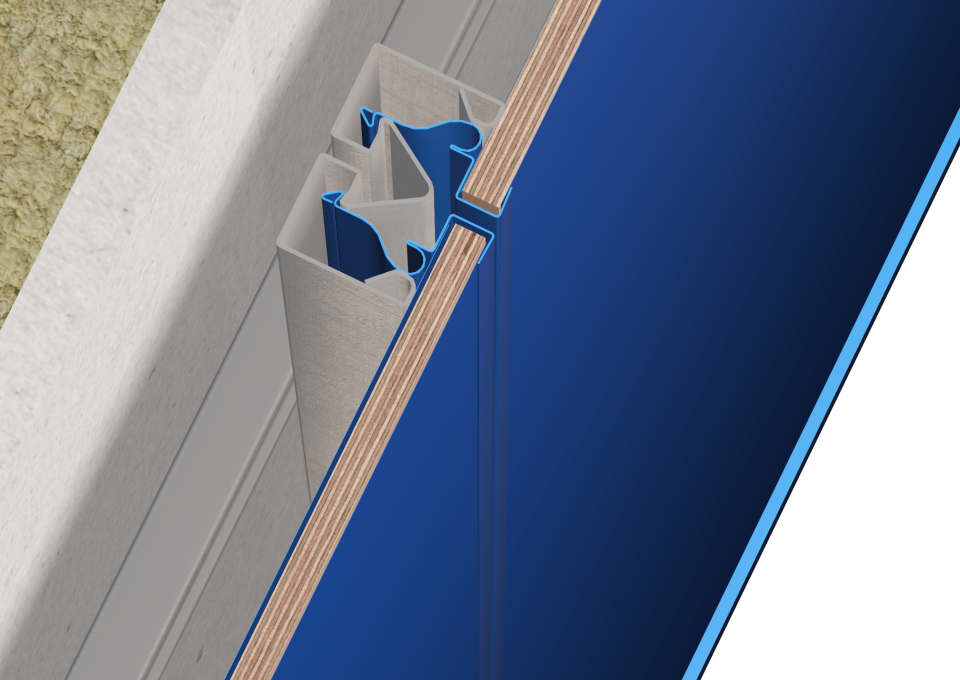

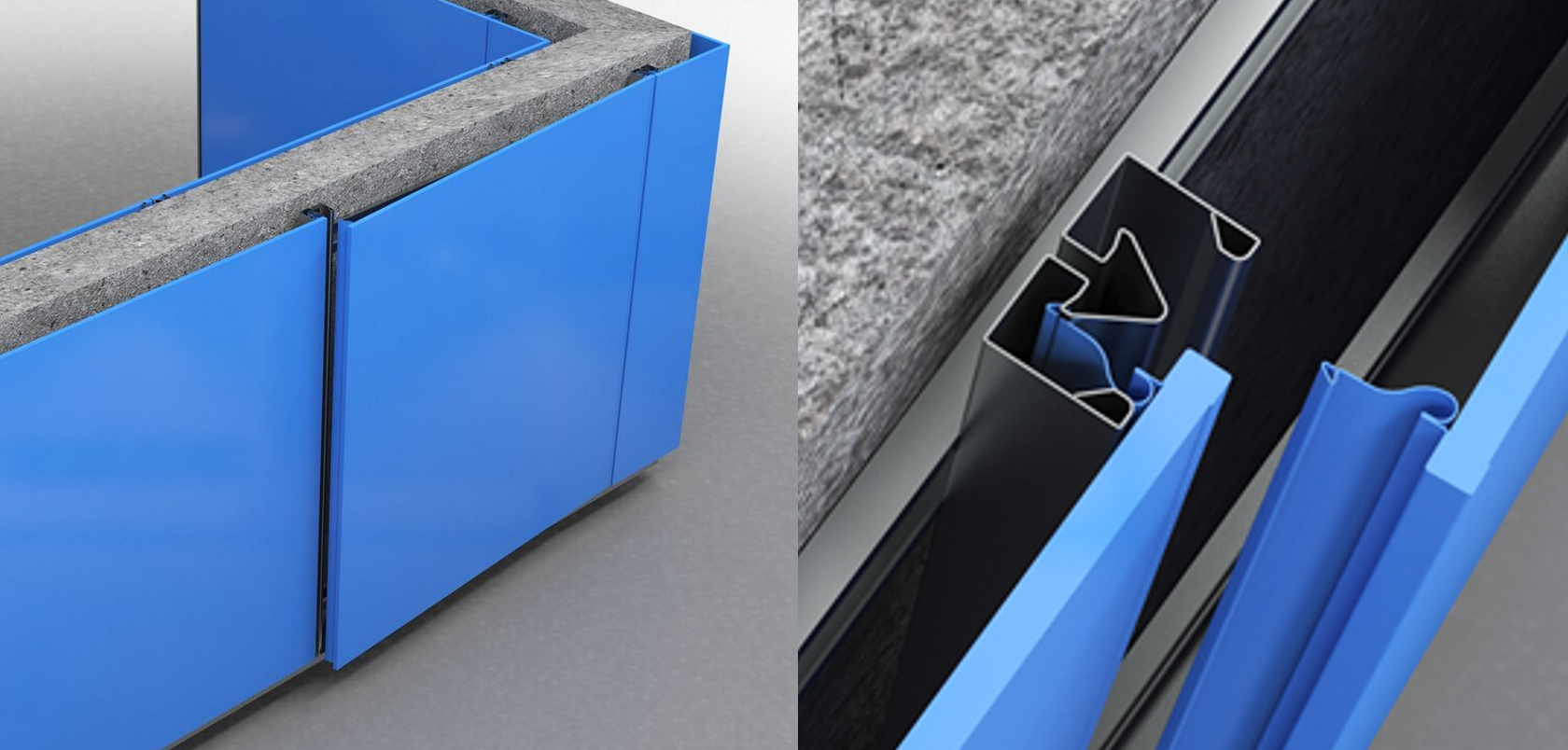

Typically Trisofix’s Fast Fit clip is factory fitted to prefinished panels but can also be fitted on site offering hybrid functionality and flexibility for installers.

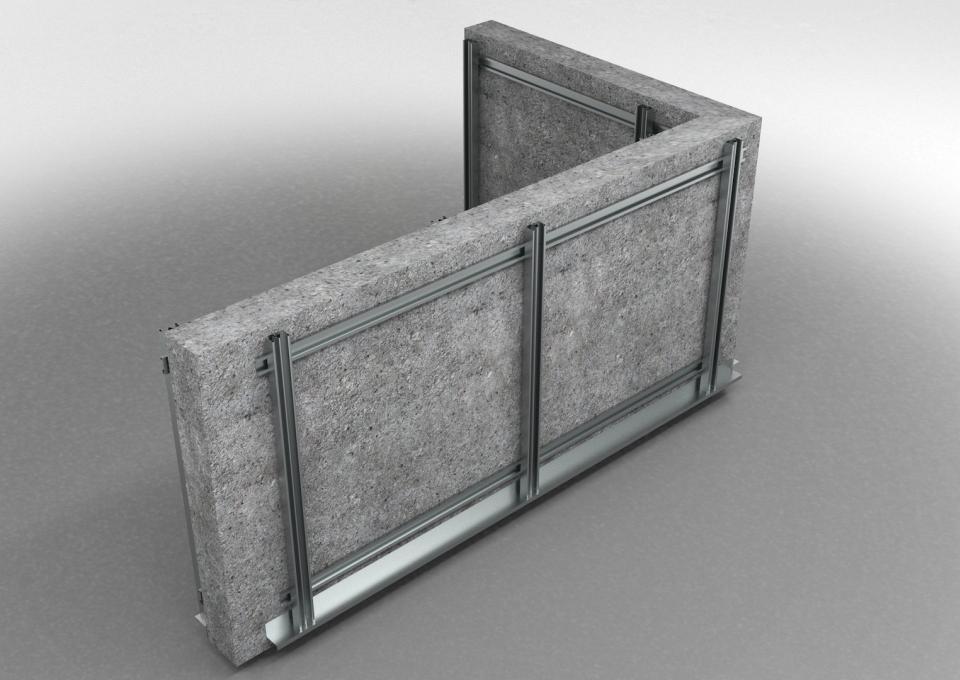

Trisofix creates a 55mm cavity behind prefinished panels, which when combined with the individual panel demounting, provides easy access to any services behind, simplifying and speeding up M&E installation.

The robust clip can be continually reinstalled without compromising strength or integrity, and allows panels and products to be removed, replaced, relocated and reused.

While Trisofix™ is fast to fit, the mounting system combines its usability with exceptional strength and durability credentials.

EN-Construction-Product-Trisofix-Sustainability

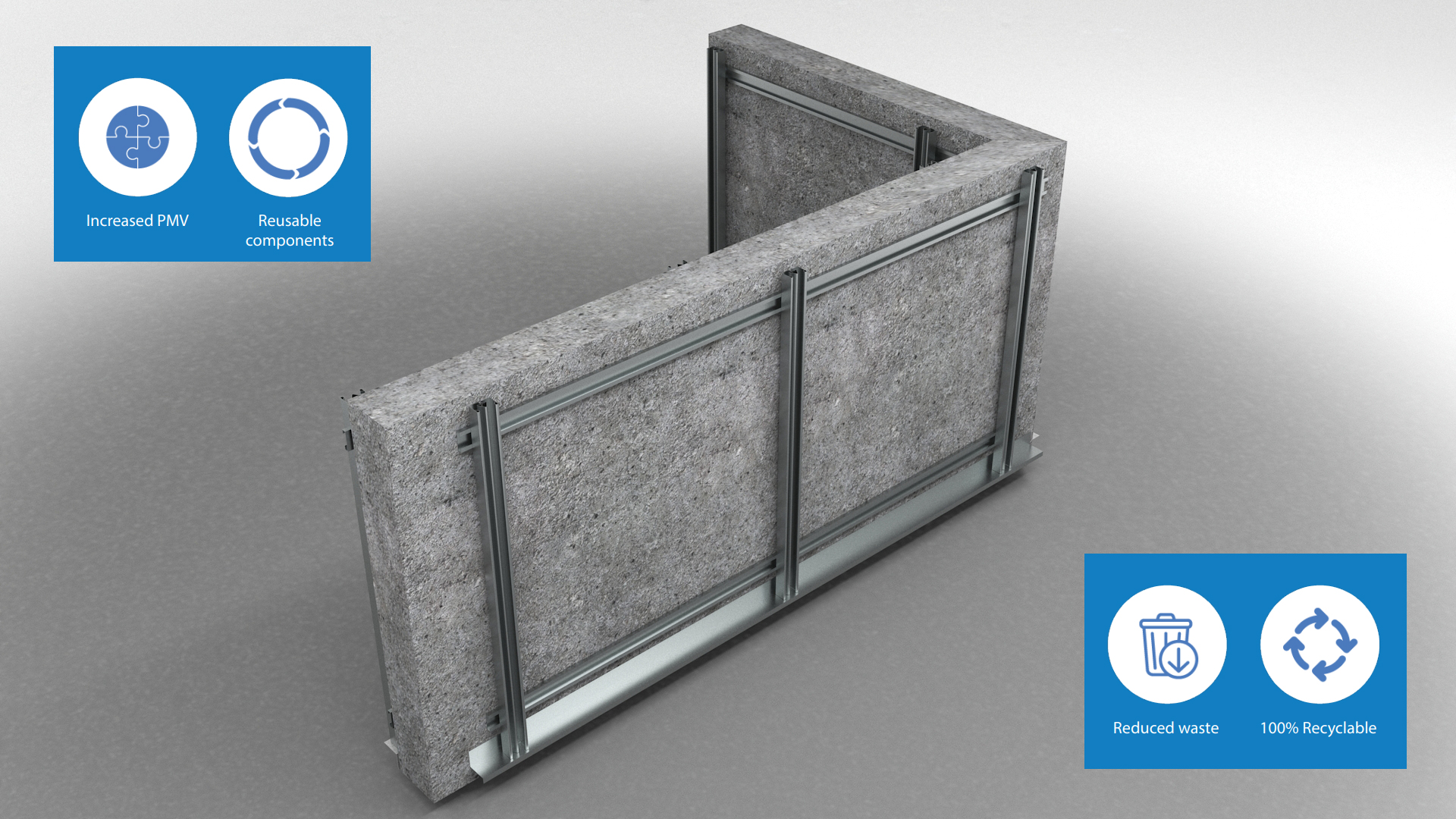

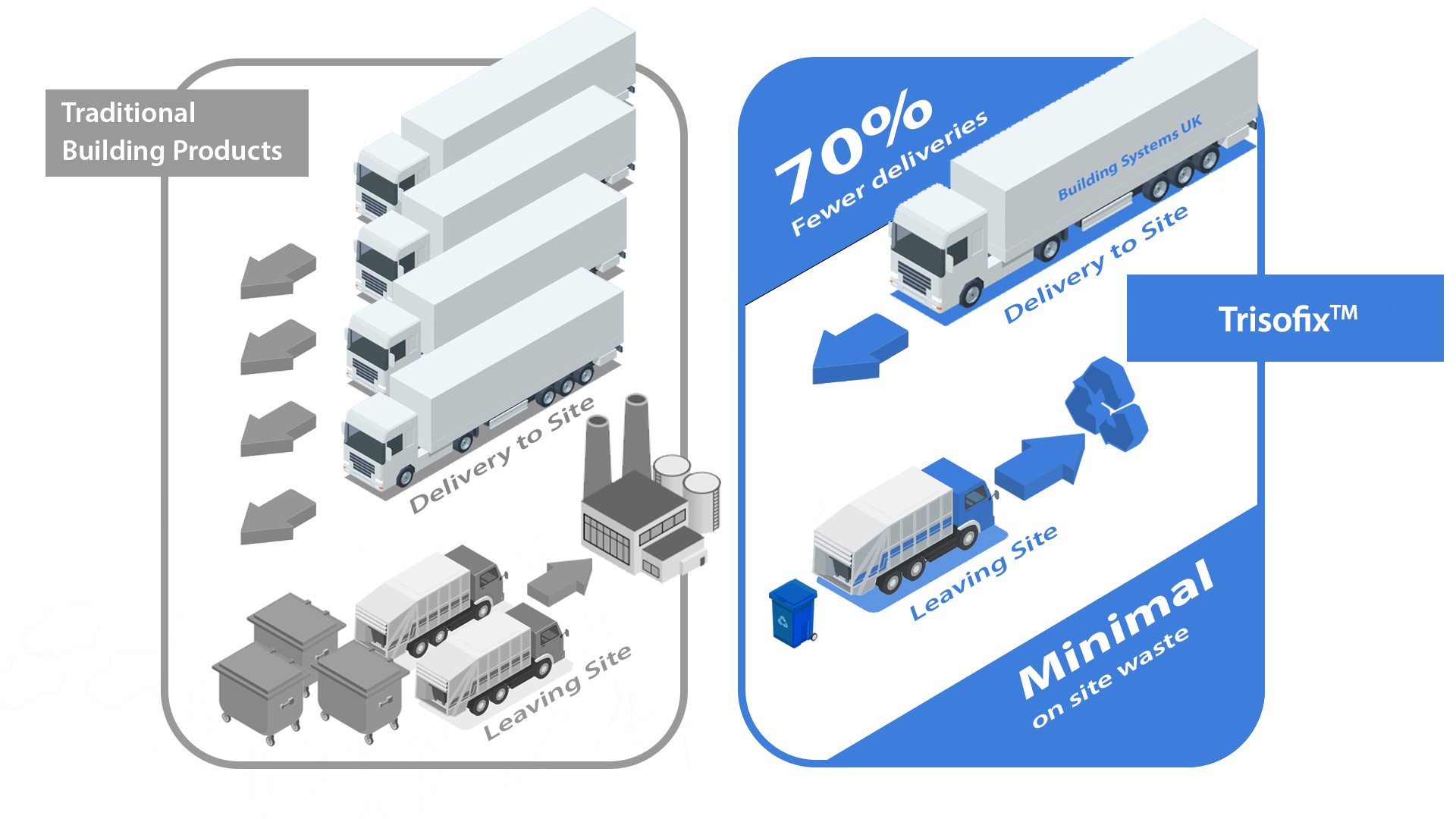

Trisofix™ is a platform solution that can be used in combination with multiple panels and product types to create integrated fit out or façade systems. The efficiency of a DfMA (Designed for Manufacture and Assembly) approach to construction delivers considerable reductions in Carbon impact during installation.

The Trisofix™ components, when combined with pre-finished panels and products, creates a kit of parts, that results in fewer deliveries to site and minimising on-site waste.

With less trades and a condensed installation time on site, Trisofix™ can drastically reduce the number of labourer journeys and overnight accommodation stays during the finishing stages of a build.

Trisofix™ enables products to be individually demounted and reinstalled time after time, facilitating relocation and reuse of wall panels. With a design life of up to 60 years, the mounting system enables buildings to be adapted and upgraded as future technologies emerge, minimising the waste and disruption typically associated with refurbishment. With all Trisofix™ components being steel based it’s 100% recyclable when it eventually needs replacing.

EN-Construction-Product-Trisofix-Kit of parts

Quick and easy installation

The patented Trisofix™ universal mounting system uses high grade coated steel components. The system fixes back to any structural wall type and can be used throughout a building, both for façades and internal fit out.

Typically Trisofix’s panel clip is factory fitted to prefinished products such as Trimawall’s performance panels but it can also be fitted on-site offering hybrid functionality and flexibility for installers.

| Part | Description | Material | Dimensions | Standard Lengths | Weight (kg/ln) | |

| 1 | Horizontal Mounting Rail | Lipped C section provides main mechanical fix into structural wall | 1.6mm Galvanised steel | 55mm x 20mm | 3000mm | 1.5 |

| 2 | Base Angle | Z profile create a level base for panels and support for skirting | 2.0mm Galvanised Steel | 65mm x 60mm x 65mm | 3000mm | 3 |

| 3 | Sliding Connector | Twist in fit steel connetor allows easy positioniong of vertical rails | 1.0mm eCoated spring steel | 62mm x 32mm | n/a | n/a |

| 4 | Vertical Retaining Rail | Push fitted onto sliding connectors it then provides the receptor for Trimawall panels | 1.0 mm Galvanised steel | 53mm x 34mm | 2800mm | 1.7 |

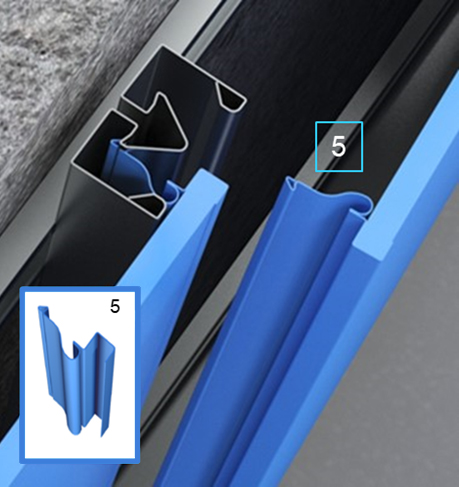

| 5 | Trisofix™ panel clip | Designed to be factory or site fitted to panels, Trisofix’s roll formed steel clip allows panels to push fitted into the vertical retainer, automatically settling to the desired panel centres without the need to precisely measure and locate each fix. | Roll formed steel | 17 x 43mm | NA | 0.385 kg / lm |

EN-Construction-Product-Trisofix-products-in-practice

Utilising the Trisofix™ universal mounting system Building Systems UK's Trimawall® has been designed to facilitate the move to high quality off-site build solutions that can radically change the speed, safety and environmental impact of onsite construction.

Trisofix allows Trimawall’s high performance Colorcoat® steel skinned panels to be installed by semi-skilled labourers, removes the need for wet trades and avoids plastering dust.

First used on the SEISMIC demonstrator at BRE Watford Trimawall is now being adapted for healthcare and secure applications as well as the standard education and office fit outs.

EN-Construction-Product-Trisofix-Tool-Free

Fast & efficient wall finishing

The Trisofix™ patented clip system that is pre-applied to the vertical edges of the composite sheet in our factory can be used to apply and mount various panel types within the construction market including Building Systems UK's Trimawall steel skinned composite panels.

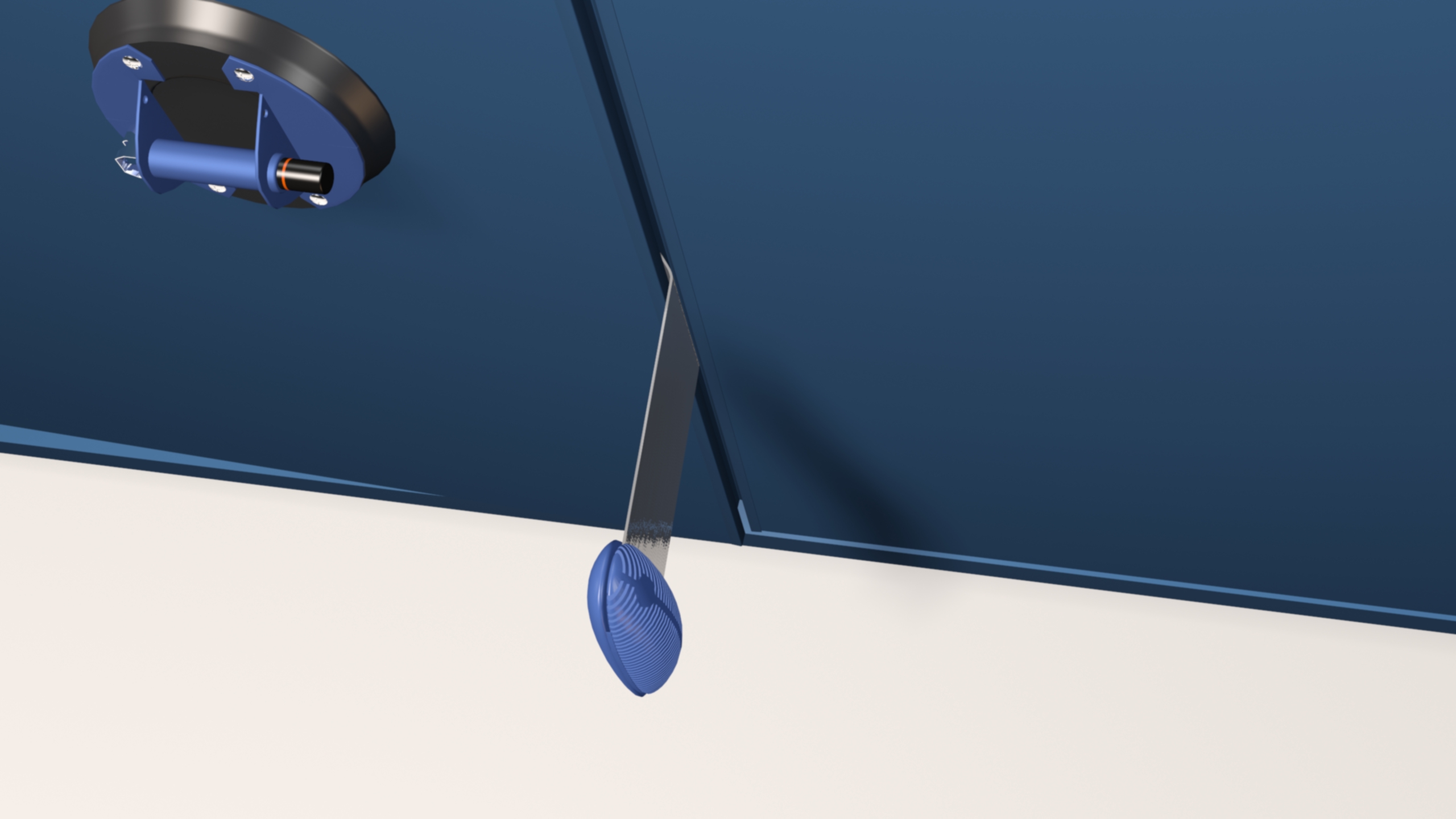

On-site, panels can typically be lifted with vacuum lifters and push fitted by a 2-person installation crew. With the pre-finished panel requiring no additional wet trade finishing Trimawall® helps simplify and condense the total fit out and finishing process, however this universal mounting systems can be used not just for steel panels but other various panel types and materials.

Individually demountable panels

A good example of the Trisofix™ universal mounting system is the use of Trimawall® panels which can be individually demounted by a 2 person crew using vacuum lifters and the Trimawall demounting tool - this process can be used for other panel types. With the use of Trisofix™, panels can be demounted and reinstalled multiple times without compromising performance or aesthetics. Not only does this allow for easy access to the M&E services within the cavity for maintenance or upgrading, but it allows panels to be relocated, reused, replaced to help reconfigure and enhance buildings over time.

EN-Construction-Product-Trisofix-downloads

Find related downloads below for your project specification:

EN-construction-Building Systems UK-Trisofix-brochure

Trisofix™ universal mounting system brochure

EN-construction-Building Systems UK full range at a glance

Building Systems UK full range at a glance

EN-Construction-Approval_or_Certificate-Responsible Sourcing BES 6001 certificate No. 651382-uk-ireland

Responsible Sourcing BES 6001 certificate No. 651382

EN-Construction-Book a CPD

We offer a range of face to face and online CPDs aimed at Engineers and Architects

These free seminars can be booked at any time between 9am and 5pm. Our online webinars can all be delivered via Skype for Business and Teams, but we can consider other platforms if this will not work for your practice.

Below outline the CPDs we have available - Book yours today

- Decarbonising your structural hollow section designs

- Essentials of Structural Hollow Sections

- Welded Joints in Tubular Steelwork - Eurocode 3 Part 1-8

- Concrete Filled Hollow Sections - Composite Design – Eurocode 4

- Composite Floor Deck in Construction

- Structural Roof Deck in Construction

- Specifying metal clad envelope systems in accordance with ADB2 of the building regulations and the value of large scale system testing

- RIBA 2030 climate challenge: How steel building envelope solutions contribute

- Pre-finished steel standing seam systems for roof & wall cladding

- CDM regulations 2015 and their impact on steel building envelope specification.

- Steel building envelope systems for non-domestic buildings

- Steel for roof and wall cladding

EN-Construction-Contact-BSUK envelope

Building Systems UK technical team - Building Envelope