Overview

Heavy Gauge Decoiling – Llanwern is focused on supplying hot-rolled sheet for a wide variety of market applications. Located at Llanwern, South Wales, it employs two decoilers to process the full range of Tata Steel hot-rolled coil. It is a new processing hub, set up following many years of successful heavy gauge decoiling at sites in Dudley, Wombourne and Llanwern.

Customer benefits

Heavy Gauge Decoiling – Llanwern operates with high levels of automation. Key line parameters in areas such as the levellers and stacker are controlled on a coil-by-coil basis. This ensures a consistently superior product with respect to flatness and sheet presentation.

The decoiling hub offers our customers a wide range of benefits:

- Reduced lead-times. The hub is located adjacent to Tata Steel’s Llanwern hot strip mill, with direct rail links to the nearby Port Talbot hot strip mill. Th

- is means it is ideally placed to benefit from increased stock visibility and reduced lead-times - providing customers with a more responsive service

- Superior sheet flatness. A £11m investment in Europe’s most powerful strip decoiler delivers superior flatness across the widest possible range of dimensions and grades.

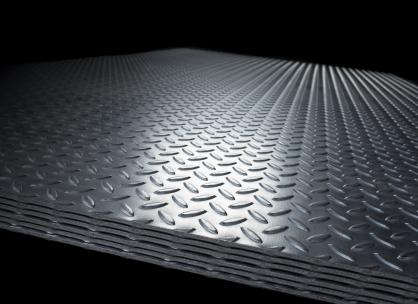

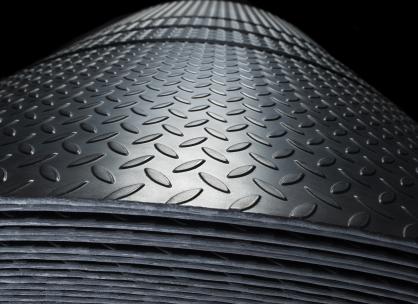

Sheets up to 25mm in thickness and grades up to 1600N/mm2 tensile strength can be readily decoiled. - Ease of fabrication. In-line brushing of the surface during the levelling process, combined with indoor storage of coils after rolling on the nearby hot strip mills, provides a consistent and clean surface finish. This makes it ideal for fabrication without intermediate surface treatment.

- Reduced processing time. We are able to side-trim during the decoiling process - offering tighter dimensional tolerances than a mill-edge sheet. This means there is no need for additional processing time associated with a sheared product.

- Security of supply. We offer a unique combination of two decoilers located adjacent to our hot strip mill. It means we can provide customers with a secure supply and sufficient capacity to support your growth plans - without compromising service.

| Process | Sheet Width, max (mm) | Sheet Length, max (mm) | Sheet Thickness, max (mm) | Comments |

|---|---|---|---|---|

| Decoiling | 2100 | 17000 | 25 | Maximum thickness of Hot-rolled pickled & oiled is 12mm. |

| Maximum thickness of Durbar® floor plate is 12.5mm. | ||||

| Maximum tensile strength is 1600N/mm2. | ||||

| In-line side-trimming available for exacting width tolerances. |

Please contact us if you have any special requirements. You can find details on how to get in touch with us in 'Contact Us' below.

Heavy Gauge Decoiling – Llanwern can provide a number of services to complement our best-in-class processing capability.

- Liaison engineers. Our liaison engineers have detailed knowledge of our products and processes and how they interact with those of our customers. Our engineers are available to work closely with customers from the earliest stages of a project – offering significant experience in new part introduction and project management.

- Product packing. Various options are available to ensure our product arrives in optimum condition.

- Supply chain. We are experienced in the management of Kanban/JIT and other supply arrangements. We utilise complete IT systems that allow you to focus on your own processing activities with peace of mind regarding security of supply.

Heavy Gauge Decoiling – Llanwern benefits from a number of supporting activities and features to provide customers with an optimum solution.

- Integrated supply chain. Heavy Gauge Decoiling – Llanwern is part of an integrated supply chain. We make steel in Port Talbot or IJmuiden, we hot roll the steel in Llanwern, Port Talbot or IJmuiden, and we decoil it in Llanwern. The majority of sales will be produced and processed in South Wales, limiting unnecessary transportation and reducing order lead times.

- Full product traceability. The Tata Steel supply chain ensures we are able to manage product traceability effectively from primary production through to despatch.

- Product development. As one of the world’s largest steel producers, we are able to offer customers an increasing range of innovative products - exploiting the broad capability of our hot rolling mills and decoiling facility.

EN-Service centres-Contact-Heavy Gauge UK Llanwern

Heavy Gauge UK - Llanwern Decoiling

CEP Offices

Llanwern Works

Newport, NP19 4QZ

United Kingdom