Common fastener-related problems on site are typically as a result of using the incorrect installation tools. All too easily, the correct equipment is being substituted with other tools that are commonly found on any building site.

However, using these alternative tools can lead to issues such as surface damage and over compression of the construction.

With the growing use of higher tensile (harder) steel grades in the supporting steelwork, the correct choice of tool is now essential to avoid additional costs and increased installation time associated with burned out and aborted fixings. Using precision engineered fasteners and the correct tools associated with them improves installation times and quality. This then ensures optimum mechanical performance of the fastener and the integrity of the building envelope.

Self-drilling fasteners are designed to be installed with the constant rotational drive of a purpose-designed screw gun. The built-in drill points do not perform well at very high speeds; therefore, a maximum speed of 2000 rpm is recommended. This may appear counter-productive, but this slower speed will contribute to reducing the risk of burn-out of the fixing. Similarly, once an attempt at drilling a hole in the material has failed, the steel support in the area of the failed fixing hole has now become case hardening, making further attempts in the same spot even more challenging.

To install the self-drilling fasteners requires the use of either a battery screw gun or a 110V screw gun, with the correct compatible head socket / bit, fitted with an adjustable depth locating nose piece.

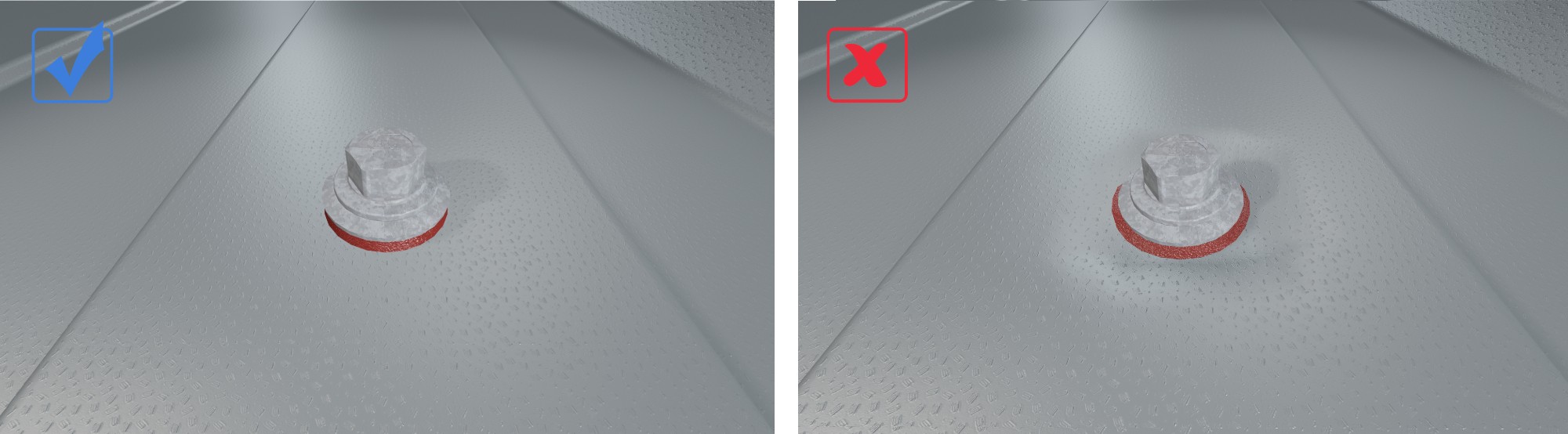

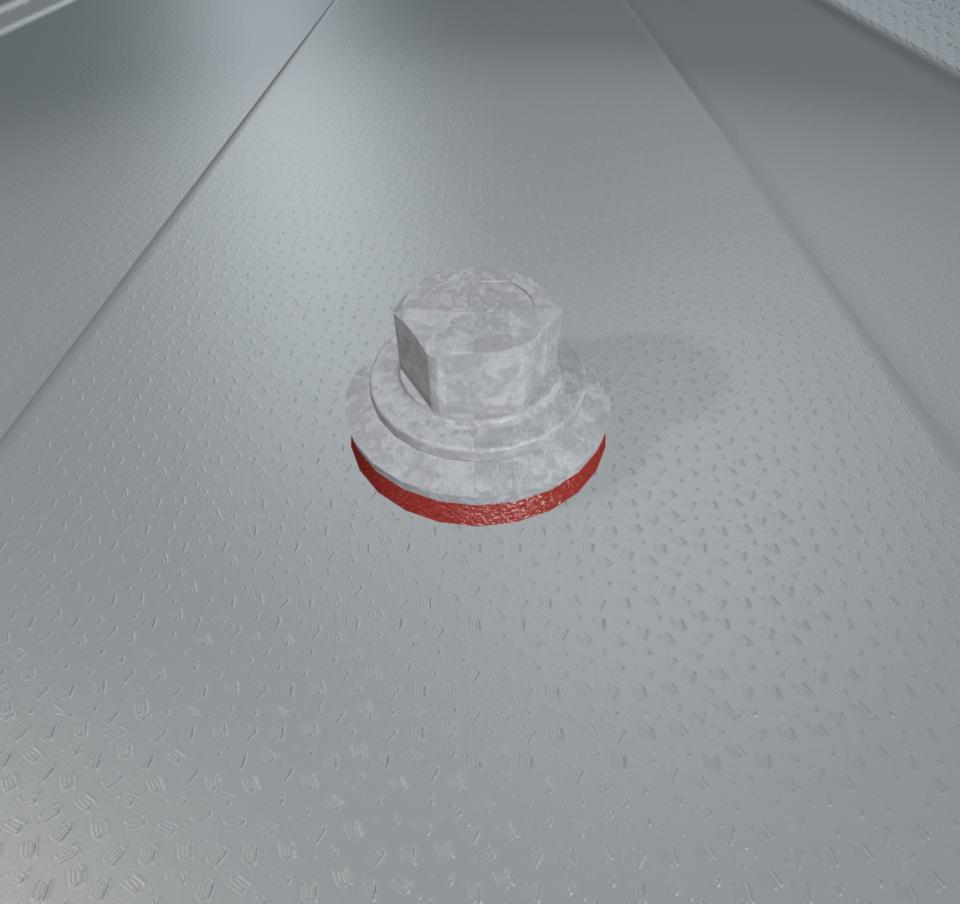

The driving socket should be deep enough to ensure that the flange at the end of the socket makes contact with the base of the head of the fixing. Doing this will ensure the tool is drilling in the fastener in the most efficient way, along with preventing damage to the fixing and work area. This is particularly important when using magnetic sockets, where the socket is shallow and increases the risk of damage to the head of the fixing. It is important to keep the socket free from swarf as the magnet naturally attracts the waste material, this ensures the socket is properly engaged with the fixing and prevents damage to the coating of the fixings and the work face. The socket recess must also be deep enough to clear the top of the fastener head, ensuring the fixing is correctly engaged into the socket.

When drilling, avoid applying excessive pressure to the screw gun whilst the fastener is drilling through the material. This is counterproductive to the process, increasing the risk of the fasteners ‘burning out’. The exact speed of the screw gun will vary depending on the fastener type, supporting steel and substrate. The slower a fixing is installed, the higher the mechanical performance achieved as there is less likelihood for the thread to strip the metal substrate and the slower speed prevents case-hardening the substrate, allowing the fixing to cut into the material as intended.

Impact drivers should not be used. The repetitive impact action will lead to fixing failures, reducing the fastener pull-out performance, and damaging the coating. The use of unsuitable tools, such as impact drivers or dry walling tools, to apply fixings may invalidate any warranties provided. Similarly, dry walling screw guns tend to run at up to 4000rpm which will exceed the fixings recommendations. Again, these should not be used.

Always:

- Install roofing and cladding self-drilling fasteners using either a battery powered screw gun or a 110v screw gun.

- Ensure that the screw gun is fitted with a correctly adjusted depth locating nose piece (unless the fastener has features to prevent overdriving)

- Install roofing and cladding self-drilling fasteners at speeds less than 2000 rpm even if the fastener has features to prevent overdriving

- Ensure correct sockets and drive bits are used

- Any magnet must be clean and recessed deep enough to clear the head

- External sockets must drive on the flange at the base of the screw head

- Always use the correct PPE to avoid personal injury

Do not:

- Install roofing and cladding fasteners with either an impact driver or a dry wall screw gun. The repetitive action of an impact driver will lead to fixing failure and dry wall tools operate around 4000rpm, well in excess of recommended installation speeds

- Apply excessive end loads (bodyweight force) via the screw gun whilst the fastener is drilling, particularly on thicker hot rolled/heavy section steel supports. This not only increases the risk of damage to the fixing or material, but also increases the risk of injury to the installer

Finally, when installing self-drilling fasteners into different types of supporting steel, the following guidance on tool speed should be considered:

- Light Section Rail: 1800-2000 rpm

- Heavy Section Rail: 1800 rpm maximum

- Stitchers into 2 layers of 0.7mm thick steel: 1800-2000 rpm

Please contact our Technical Department for further details on the correct fastener specification for use with our systems or use our online specification tool to help you create the right specification for the performance that suits the needs of your project. Doing this will give you peace of mind that cladding components are compatible and perform together as a system.