The need for distribution centres and warehouse construction is at an all-time high - with the rise of online shopping this brings with it an increased need for warehouse space and large distribution centres, with online retailers and businesses requiring a larger amount of stock in order to meet growing customer demand.

The need for distribution centres and warehouse space is at an all-time high - with the rise of online shopping this brings with it an increased need for warehouse space and large distribution centres, with online retailers and businesses requiring a larger amount of stock in order to meet growing customer demand. The need for new warehouse construction is clear.

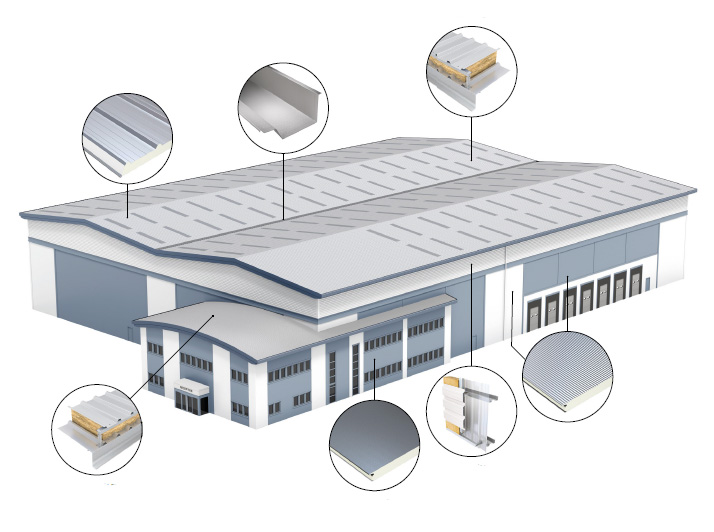

While there are many ways to build warehouse facilities, it is important to carefully consider the materials used for warehouse construction, in order to ensure that the country’s new supply of warehouses are built to serve the retail and logistics industries for many years. Steel cladding systems are, of course, an obvious choice, well-known in the industry for speed of build, thermal performance and durability.

The need for distribution centres and warehouse construction is at an all-time high - with the rise of online shopping this brings with it an increased need for warehouse space and large distribution centres, with online retailers and businesses requiring a larger amount of stock in order to meet growing customer demand. The need for new warehouse construction is clear.

While there are many methods of warehouse construction, it is important to carefully consider the materials used for its construction, in order to ensure that the country’s new supply of warehouses are built to serve the retail and logistics industries for many years. Steel cladding systems are, of course, an obvious choice, well-known in the industry for speed of build, thermal performance and durability.

Below are six of our top tips to consider when creating a new warehouse

1. Take a systems approach

When looking for the steel building products required for a warehouse’s construction, taking a systems approach can be widely beneficial, both for yourself and your client. Rather than considering each individual wall, roof and flooring element in isolation, a systems approach focuses attention on how components in the building envelope will work together as a whole, providing you with the assurance that all parts will complement each other and provide the desired performance.

2. Work with a manufacturer who offers dedicated specification and installation guidance.

Manufacturers are generally the experts in how to get the best out of their products for your specific building type. So it’s always a good idea to liaise with the manufacturers technical team who can advise on both the best specification, and give any installation guidance to ensure the building will carry on performing as it was intended. For example, Tata Steel’s not only provides a full systemised building envelope solutions, but by completing an initial specification via the online specification tool, they provide tailored, technical support throughout the whole specification and construction process. This includes on-site installation checks, prior to the guarantee being issued, to provide additional assurance that the building will perform as designed.

With warehouse construction often being a significant investment for a company, representing an expansion of its business reach and capacity, this level of assurance will understandably be well-received.

3. Consider a warehouse’s sustainability and environmental impact.

If you are looking to create a warehouse building envelope that is lightweight, as well as thermally efficient, then system selection plays a key role. PIR insulated composite panels such as and are the perfect choice in this situation. With the added bonus that they are quick and easy to install to provide a building that achieves a high level of air-tightness. Combine this with a highly reflective liner for the internal skin and you will also significantly reduce in-use CO2 emissions by 2-3%, improve daylight factor by 10% and achieve lighting energy savings of up to 12% per annum.

Our support continues through on-site checks, ensuring the products installed are in accordance with the specification. In addition, if your client’s aspirations are for the highest possible BREEAM or LEED rating then look for a manufacturer who can develop product-specific EPDs to recognised standards. Find out how here.

4. Choose a cladding system that has been fire tested

Fire performance is, of course, a prominent concern within the industry, with strict requirements and increasing pressures.

This is another area where taking a systems approach can be beneficial, providing an understanding of how the products will behave and react together as a complete unit in the event of a fire, rather than considering each materials’ isolated performance. The type of system used is dependent on the required fire rating, but in most circumstances both built-up systems and PIR insulated panels are suitable for warehouse buildings. Always check for independent certification, to ensure that the systems you choose can be installed on projects with confidence.

In addition to building regulation requirements, the insurance industry within the UK has developed additional large-scale reaction to fire tests. The primary focus of these robust large-scale system tests is asset protection, providing an excellent indication of how a complete envelope system will behave in a fire. The evidence obtained through these approved steel faced insulated PIR panels has been reinforced in the way they react to fire in real building fire situations. Case studies have proven the performance of PIR panel systems across the world, showing that in extreme cases of fire load these types of panels do not propagate fire. Contractors should therefore ensure that products specified are certified to either LPCB 1181:1 or FM Approval.

5. Keeping the noise down!

For projects where sound reduction from within the building is also a prominent concern - for example, if a warehouse was to be constructed near a residential area or was to house industrial equipment – consider using a built-up system, such as Tata Steel’s systems. These systems are generally formed of a mineral wool insulation core placed between two separate pieces of steel cladding, held apart using a steel spacer bracket and rail. While requiring more experienced labour and time to construct, built-up systems offer superior sound reduction qualities, preventing the transmission of noise from disturbing those outside of the warehouse, as well as being wholly non-combustible.

6. Consider what type of pre-painted steel you use for your cladding system

We’ve already discussed the benefits of selecting a high reflective liner, but another key consideration is selection of the external skin as not only does it provide the aesthetics of the building envelope but it also provides protection against weathering and corrosion damage. This is particularly important for warehouses as they are often constructed on an industrial district or zone, or exposed brownfield land site. High quality pre-finished steel is known for providing the highest levels of resistance against corrosion and weathering and in return reduce the costs of maintenance. Tata Steel’s most durable product is and is used on many buildings in aggressive environments; while , offers both corrosion resistance and resistance to colour fade. Both are available in a wide range of vibrant colours, and are backed by a for up to 40 years, providing owner with a long lasting building and an on-brand aesthetic.

It is clear that the warehouse and logistics sector presents a booming market for construction, with increasing need for high-performance warehouses to be constructed. As such, it is important that contractors start taking more of a systems approach, ensuring that the individual building components will work together as expected, and carefully consider the materials used for its construction, in order for the country’s businesses to be provided with the high-quality warehouse space that it so desperately needs.