Curved roof structures have become a popular trend over recent years with the curved lines providing aesthetic appeal and the practical advantages of lower apex heights and parapet requirements

As with any roofing type, designing and installing a tight building enclosure is essential for delivering a high performing building. systems provide a trapezoidal through fixed solution to achieve this on many curved roof radii.

The system uses the existing product parameters in relation to self-curving in addition to development efforts to ascertaining the most positive weathertight method of fixing the external profile. Third party weatherability testing has confirmed confidence of this specification which has been further assured with the having already been successfully installed on several projects across the country.

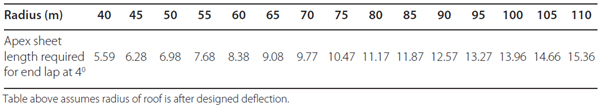

The system is defined by the apex sheet which needs to be long enough to ensure that the end lap of the profile is below the 4 degree pitch of the curved roof. The table below can be used to ensure the apex sheet length is long enough to guarantee this.

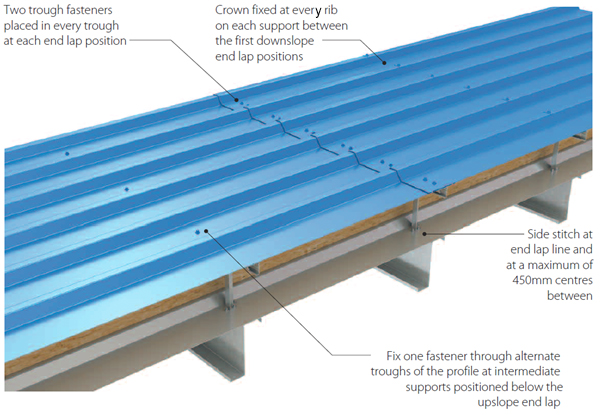

With regards fastener location into the outer profile, sheets that lay below the 4 degree point on the curve can be installed using one primary fastener with a 19mm washer within the trough of the profile, at the ends and intermediate positions.

The apex sheet which will be positioned above the 4 degree point of the curve requires a different fixing method. Here, the primary fasteners fix down the sheet through every crown at each support position and incorporate a saddle washer.

Where the apex profile laps with the down slope sheeting the end lap is sealed with two rows of high performance butyl strip sealant and fixed with two fasteners in each trough.

As part of the development of the system, and as advised in BS 5427:2017 ‘Code of practice for the use of profiled sheet for roof and wall cladding’, the system was independently testing at the BRE in accordance with BS EN 12865 ‘Hygrothermal performance of building components and building elements’.

This test assesses water penetration when subjecting the system to air pressure and a deluge of powerfully sprayed water.

A full sized roof section was constructed which followed a 40m radii. This being the minimum natural curve for the profile. Then a containment box was built around the roof construction to contain the water and air pressurisation required in the test.

The external surface of the test specimen was sprayed continuously with water while the closed rig generated a pulsating air pressure difference which increased in steps of 150 Pascals. There was no water leakage found until the pressure reach 900 Pascals.

Please contact our Technical Department for further details or use our online specification tool to help you create the right specification for the performance that suits the needs of your project. Doing this will give you peace of mind that cladding components are compatible and perform together as a system.

Find out more about our Trisobuild® systems