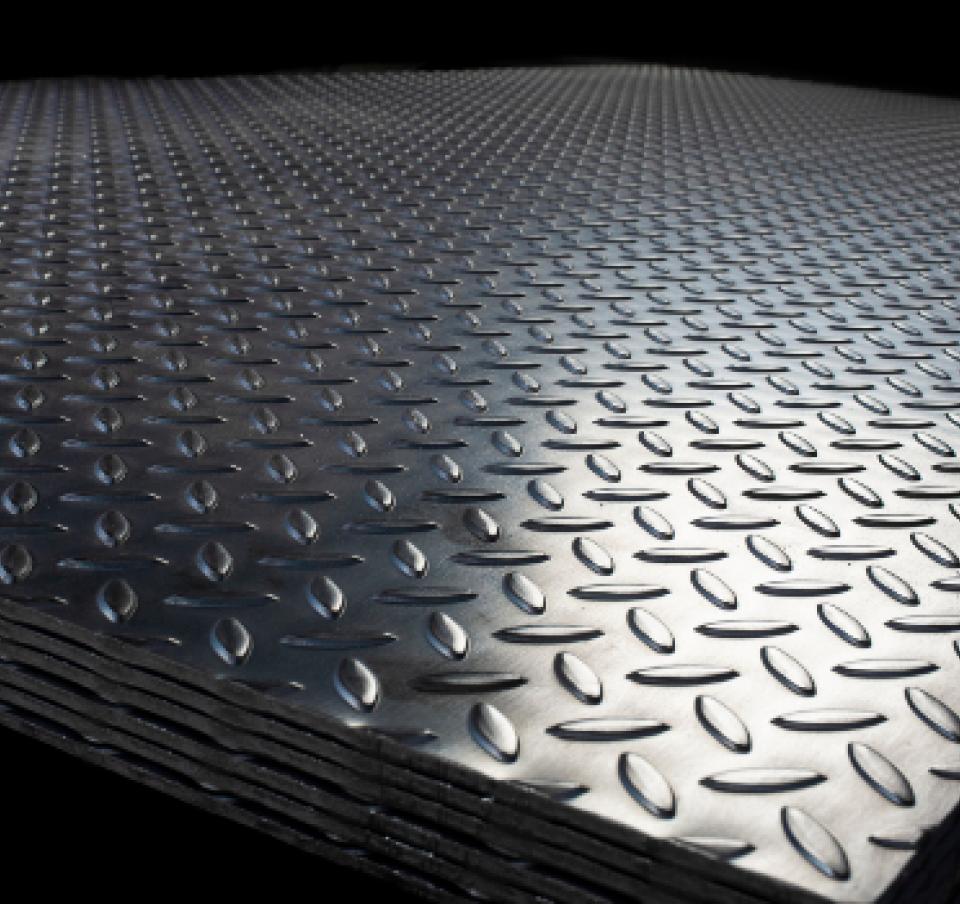

Steel floor plate, sometimes referred to as diamond plate, chequer plate or tread plate, has undoubtedly prevented many accidents by providing a safe, anti-slip surface.

Over the past 50 years, steel floor plate, sometimes referred to as diamond plate, chequer plate or tread plate, has undoubtedly prevented many accidents by providing a safe, anti-slip surface. And a new study shows that the unique patented pattern of studs on genuine Durbar®, Tata Steel’s brand of steel floor plate, continues to provide outstanding slip resistance.

According to the latest guidance from the Health & Safety Executive, over a third of all major injuries reported in the UK are caused as a result of a slip or trip – in fact, the biggest cause of non-fatal accidents. That amounts to 172,000 injuries to workers every year, not counting injuries to the general public. Products that contribute to safer passage over surfaces, can reduce the risk of slips and trips, whether in permanent conditions, such as in factories, or temporary conditions, such as construction, building and planned maintenance.

Why is Durbar® the most slip resistant?

Over the years, Durbar® (only from Tata Steel - beware of imitations) has become synonymous with anti-slip flooring, whether it’s on stairways, stadia, oil rigs, weighbridges or elsewhere, Durbar® is now a part of everyday life.

Durbar® has a unique diamond pattern which, on average, is 23% deeper and has 10% more studs than other generic steel floor plates. The dense pattern of studs creates a slip-resistant surface at all angles and allows plates to be used in any direction. This is why the same product we were producing 50 years ago continues to work so well today.

To check out this claim, we recently commissioned a series of comparative tests of Durbar® and generic products manufactured to EN 13036 with either the ‘A’ or ‘T’ type patterns.

The UK HSE and the influential UK Slip Resistance Group (UKRSG) recommend the use of a standardised pendulum test to measure the slip resistance of flooring products. This test is according to EN 13036-4. The pendulum test measures the dynamic coefficient of friction and is designed to replicate a pedestrian heel strike. This has been found to simulate the most common cause of slips most effectively.

Independent tests on Durbar® using the pendulum tester have shown consistently good results in both wet and dry conditions. The measured pendulum test value (PTV) in the wet condition of 46 represents a ‘Low’ slip potential, according to UKSRG guidelines, while in the dry condition, a PTV of 73 provides a classification of ‘Extremely low’ slip potential.

Comparative tests on generic steel floor plate adopting either ‘T’ or ‘A’ patterns have shown that the unique pattern of studs on genuine Durbar® results in the lowest all-round slip potential.

Of course, the actual slip resistance of Durbar® or any other steel floor plate will depend on real-life application and the environment in which it is used. Galvanising, painting or coating Durbar® can influence the slip resistance. But these tests demonstrate that genuine Durbar still leads the way in protecting against slips.

Using Durbar® provides further benefits too. Compared to other materials like aluminium, Durbar retains its structural properties under heat better, so in a fire situation it keeps on working after other materials have lost integrity.

The market standard for over 50 years

Durbar® has been a market leading steel floor plate in the UK for over 50 years. Therefore, our current product is an exact match with existing installations, enabling concern-free refurbishment.

Durbar® is exclusively manufactured at Tata Steel’s Port Talbot site which is certified for responsible sourcing to BES 6001 for the manufacture of hot-rolled coil. It can be easily reused and is 100% recyclable at the end of its useful life. Durbar® can be galvanised or painted for additional corrosion resistance.

Durbar® is widely available throughout the UK market. We supply it in both coil and sheet format to a wide range of distribution partners. Decoiled Durbar® sheet from Tata Steel benefits from a high quality surface finish and excellent flatness due to the class-leading brushing and flattening capability of our recently commissioned new decoiling facility.

The list of applications for Durbar® keeps expanding every day – wherever anti-slip flooring is required, you will find it and increasingly it is being used purely for its aesthetic properties too. With our long-standing expertise in Durbar®, we are also in the best position to help engineers to specify the right product.

Visit our Durbar® product page for extensive advice on using Durbar®, including load capacity tables and calculation details, as well as a helpful set of answers to frequently asked questions we receive. Alternatively, call us on +44 (0)1639 602460 or email connect.durbar@tatasteeleurope.com.

At Tata Steel, we are always innovating in both our processes and our products. But sometimes, a classic comes along that stands the test of time. Durbar® is just such a classic. After 50 years, it continues to provide outstanding slip resistance. And given the increased focus on preventing serious injuries from slips and trips, it is more important than ever to specify flooring products that perform

For steel floor plate applications, we recommend genuine Durbar® - only by Tata Steel.