The building envelope design influences the building’s long term performance, with a significant impact on cost, energy usage and the environment.

The most important stage of any new construction project is the design. The building envelope design influences the building’s long term performance, with a significant impact on cost, energy usage and the environment. We know how essential it is to get these factors right, and we support our customers during this crucial design process. One example of how we worked with a specifier, based in the North West UK, to reduce build costs while still achieving the clients stringent specification for reduced operational energy is detailed below.

In practice

The project’s architects, approached our technical experts for help with the design of a 10,000m2 industrial building, for which their client required an outstanding BREEAM rating with the lowest practical operational energy requirements.

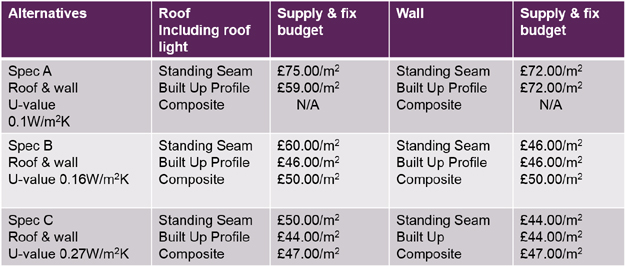

The initial draft specification for the building envelope had a 0.1W/m2K U-value for the roof, walls and floor slab to reduce operational energy losses. This specification would have significantly limited the choice of cladding options and would significantly increase the build costs, as well as the embodied CO2.

In conjunction with Oxford Brookes University, we set up a programme of work to evaluate energy, CO2 and cost savings of a number of alternative building envelope specifications that would still achieve the client’s requirements.

Assessment of these alternatives was carried out using SBEM software, as this would be used for Part L compliance and the Energy Performance Certificate (EPC) generation.

What did we measure?

The starting point (base case) building had back stop specification for the building envelope, and notional building specifications for the building services. The installed cost indications were obtained from an independent third party cladding contractor to allow an accurate comparison.

A range of building envelope enhancements were assessed:

- Roof and wall insulation thicknesses

- Use of a high reflective internal liner

- Installation of building envelope renewable energy solutions.

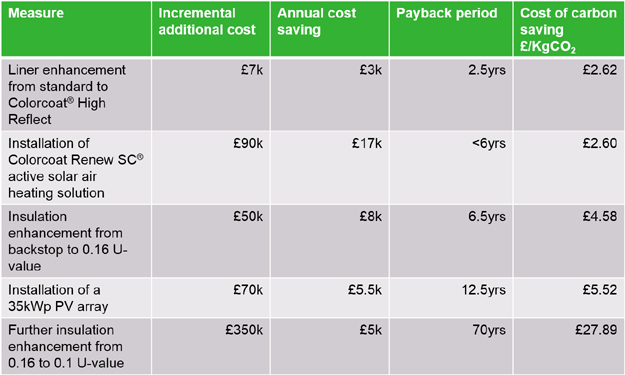

Assessment criteria were based on additional incremental costs, annual cost savings and payback, and relative cost of carbon saved per annum on operational emissions. We also assessed the increased embodied CO2 in the building envelope for the different U-values. The enhancements made no change to the building’s structure.

Results

- A roof and wall U-value of 0.16W/m2K gave the most cost effective solution

- Reducing U-values below 0.16W/m2K creates a large increase in embodied CO2 and significant cost increase for small energy savings

- Using a high reflective liner, such as Colorcoat® High Reflect pre-finished steel for the roof and walls will reduce the overall light energy requirements by around 10% and has a financial payback in less than 3 years

- Installing an active solar air heating solution (also known as a transpired solar collector), such as Colorcoat Renew SC® with a 900m2 collector should provide in excess of 20% of the building heating requirements and has financial payback in less than 6 years

- A roof-light area of 10% will provide the lowest CO2 emission rate and provide a balance between natural daylight, heat loss and the risk of summer overheating.

Energy savings

Figures are estimated based on a combination of research modelling and provided data.

Full IES simulation modelling will provide a more accurate analysis.

Conclusion

Based on the ranking table, Tata Steel recommended the following specification to achieve an operational energy performance that would be slightly lower than the original specification at significantly lower capital cost

- Trisomet® 120mm foam composite panel for roof and walls from Tata Steel

- External sheet 0.5mm

- Internal liner 0.4mm

- 900m2 active solar air heating system using perforated Trisobuild® C32 profile to south facing elevation. Recommended colour Anthracite

- 10% roof-light area with a U-value of 1.2W/m2K

This proposed specification had an EPC rating of 13. We expected to gain nine BREEAM credits and a further one for renewables (from Colorcoat Renew SC®), based on 2011 criteria.

If the client required further reduced emissions/energy costs, the next step would be to install a PV array, sized to suit these requirements.

At Tata Steel, we work closely with customers to ensure that all steps are taken to improve energy performance and savings, while helping to adopt measures that can support the environment. Our experts are committed to meeting our customers’ requirements, while taking the headache out of managing building design.

For more information on this subject or to discuss your requirements with one of our technical experts please contact Colorcoat Connection® helpline