Achieving a sustainable built environment requires collaboration and effort from every part of the construction supply chain.

Achieving a sustainable built environment requires collaboration and effort from every part of the construction supply chain. To address gaps in the adoption of sustainable approaches, it is essential to understand different perspectives from within the construction industry on the barriers to, and opportunities in, responsible sourcing.

At Tata Steel, we are committed to integrating sustainability into our business operations and are taking an insight-driven approach to understanding the industry’s thoughts on responsible sourcing. An in-depth survey we carried out captured a wide cross-section of the industry on their attitudes to sustainability and current practices.

The questions were developed with a specific focus on gaining valuable insights relating to responsible sourcing, covering areas such as influencing factors, standards and levels of adoption.

So, what are the barriers?

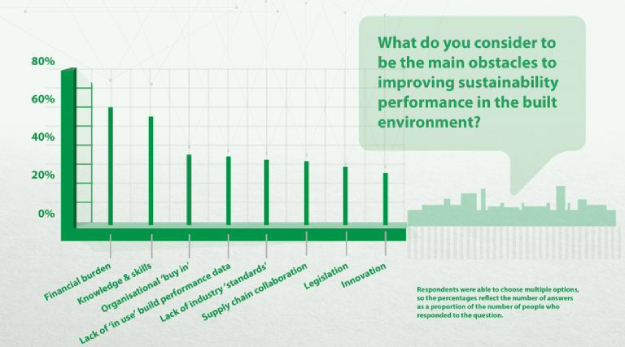

When asked what they considered to be the main obstacles to improving sustainability performance in the built environment, most respondents (60%) – who were able to choose multiple options – considered ‘financial burden’ to be the leading obstacle to improving sustainability performance.

The preoccupation around the cost implications of adopting more sustainable measures may derive from a lack of understanding of the benefits that total life cycle cost or a building’s ‘in use’ performance can generate. Sustainable development in the built environment makes business sense. In many cases, the life cycle benefits and operational and disposal cost savings will outweigh the initial capital expenditure associated with supplying sustainable construction products.

As a leading sustainability-focused steel producer for the construction industry, we offer customers access to our expertise and technical guidance, as well as our commitment to ensure that a building’s life cycle is front of mind in order to optimise resource efficiency and reduce the total cost of ownership for a construction project.

At Tata Steel, we strive to work with customers at the start of a project, during the design stage, and continue to offer technical assistance until its completion. The design stage is critical to ensuring the right decisions are made with regards to product quality, life cycle and cost. Early vendor engagement provides a real advantage to architects, main contractors and engineering designers, helping to optimise projects and leverage the benefits of different sustainable solutions in the supply chain.

The respondents’ second highest ranking barrier in the survey was ‘knowledge and skills’ (55%). This result demonstrates a potential lack of training or knowledge regarding sustainability within the construction industry. While this is evidently an important barrier to overcome, the knowledge gap is likely to be filled over the next few years, as more people share their experiences and insights and turn to experienced sustainability-focused suppliers, like Tata Steel, for advice. This in turn, should lead to best practice and sharing of those practises, helping to create a sustainability benchmark for the whole construction industry to follow.

Figure 1

Building a more sustainable future

The results of the survey provided us with tangible data from people in roles throughout the supply chain, equipping Tata Steel with a cross-market perspective of current attitudes towards sustainability. The results will help us to improve our approach to market on sustainability issues, identifying potential knowledge gaps or opportunities to increase awareness and understanding the benefits of responsible sourcing.

For further information on sustainability in the construction industry, read “Sourcing responsibly: A market insight into sustainability attitudes and practices” here.