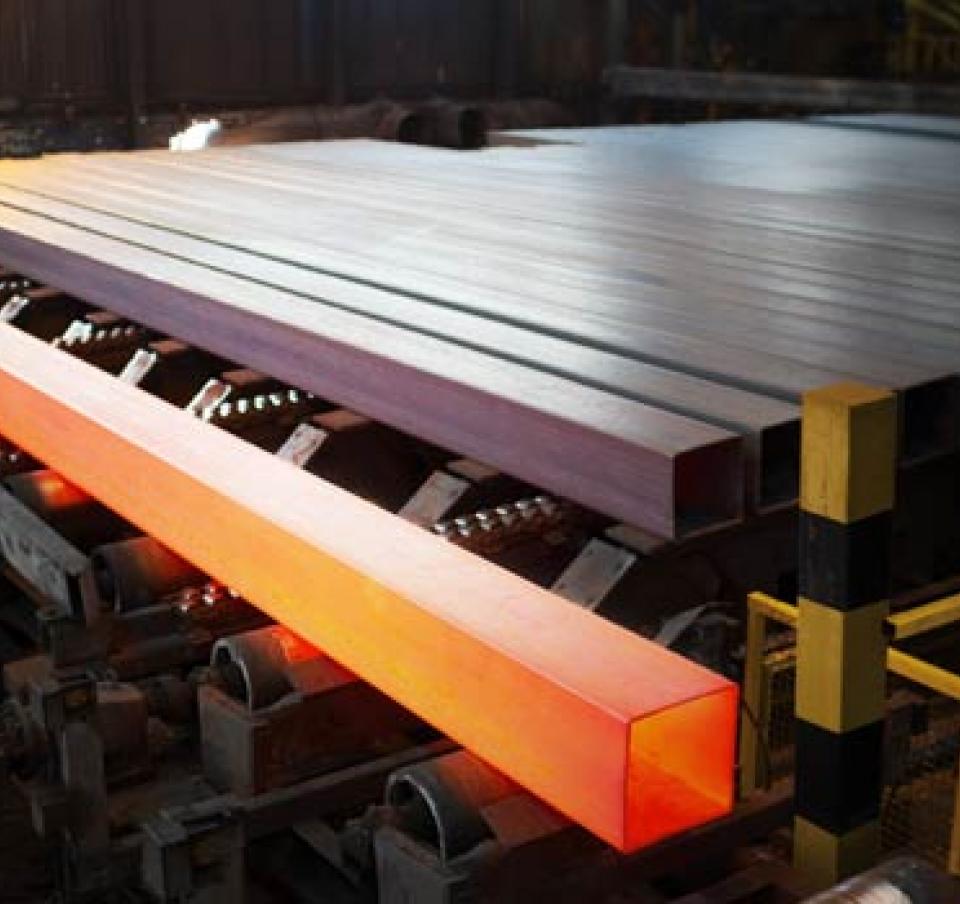

One of the key expectations that we are seeing from our customers is the increasing demands for surface quality on our range of Celsius® hot-finished hollow sections.

At Tata steel, we listen to our customers and we like to do what we can to make their business better. One of the key expectations that we are seeing from our customers is the increasing demands for surface quality on our range of Celsius® hot-finished hollow sections. Celsius® is usually painted in its final application and the requirement for high-gloss finishes means that the quality of the steel surface is increasingly important.

Our Celsius® range is produced across three different mills, each focusing on a particular size range and with unique technologies. So we have put in place a surface-quality enhancement programme across these three mills to provide the excellent finish that the market wants. A recent investment at our Hartlepool mill has moved us a significant step forward.

The Hartlepool investment of £150k has completely renewed the surface descaling system, using an innovative screw-filtration system and a set of new pumps and nozzles to provide up to 3000 psi of descaling power during hot-forming.

And the results are clear to see – even on the thickest products, the surface finish is significantly and consistently improved.

Andrew Ward, works manager at Hartlepool 20” mill said, “we’re celebrating fifty years of manufacturing tubes at the 20” mill this year and have been looking back at our achievements. It’s great to see this investment along with the laser measurement system which was installed earlier this year – we can hopefully look to the next fifty years, delivering and exceeding our customer’s needs.”