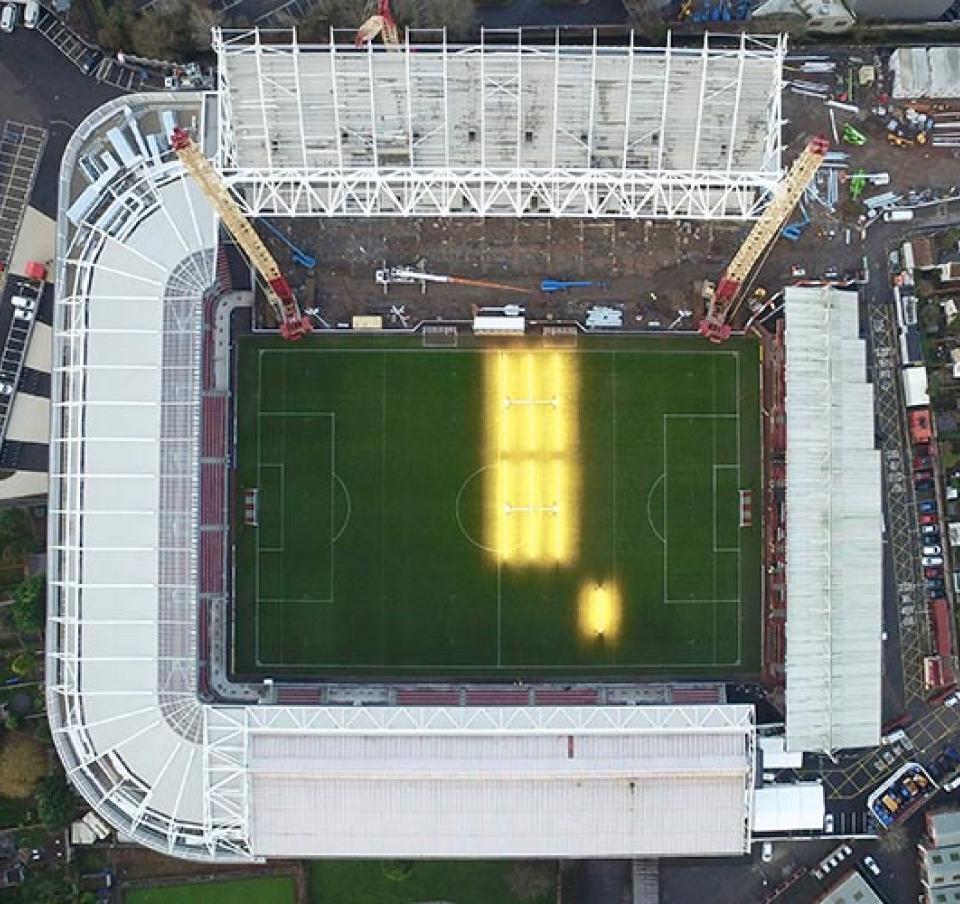

Ashton Gate Stadium

Stadia case study, Celsius®

End Client: Ashton Gate Stadium

Architect: KKA Architecture

Main Contractor: McLaughlin & Harvey Construction Ltd

Consulting Engineer: Jacobs

Structural designer and fabricator: J&D Pierce (Contracts) Ltd

Tata Steel Products: Celsius® 355 Circular Hollow Section

Year: 2016

Images: J&D Pierce Fabrication and OTIB (Bristol City Forum)

The new Lansdown Stand at Ashton Gate Stadium in Bristol was opened in 2016 as part of a major redevelopment scheme. The stand incorporates around 1,800 tonnes of structural hollow section and features a complex, triangular-shaped roof truss spanning 108m.

The challenge

The criticality of the roof members demanded circular hollow section with proven, consistent strength and reliable tolerance. Precise and reliable loading calculations were vital to the successful design of welded joints in the complex truss design.

The architectural requirement for visible truss connections – with no outstands and a continuous ‘look’ to the hollow section – also posed challenges, with complicated details required for the fabricated steel-to-steel connections.

Ashton Gate Stadium remained live during the development of the Lansdown Stand. Site constraints, coupled with the need for safe, timely and cost-effective roof installation, called for a well-considered approach to erecting the main support truss.

The solution

Celsius 355 was used in the roof’s main support truss. The rafters span from the rear of the stand, underneath the truss, and project beyond to provide additional spectator protection.

Roof and building stability was gained through use of an extensive diagonal bracing system in the plane of the roof transferred to the rear and the gables.

The bespoke truss arrangement required careful consideration of the welded joint design – especially for the most critical joints with the highest loadings.

Angus Cormie said: “We were required to carry out the CIDECT validity checks. The configurations did not match standard software output so we had many discussions with Tata Steel’s technical advisory team as we strived for acceptable output."

"Timescales were challenging and the Tata Steel team assisted and offered good suggestions to get us over the line on occasions when we were close to an acceptable result. Their support was critical in enabling us to complete the connection design” said Angus.

EN-Construction-Contact-Tubes-Technical

Structural Hollow Sections Technical Team

Tata Steel

Weldon Road

Corby

Northants

NN17 5UE