The Shoe and Boot Factory

Residential case study, Colorcoat Urban®

Client: Campbell Property UK Ltd

Architect: Willmore Iles Architects

Main Contractor: R G Carter

Tata Steel products: Colorcoat Urban® standing seam system and special colour-matched detailing which included gutters, flashings and junctions

Year: 2013

When discovered by Campbell Property the Victorian building was in a severe state of disrepair, having been neglected since closing as a sock factory some years earlier.

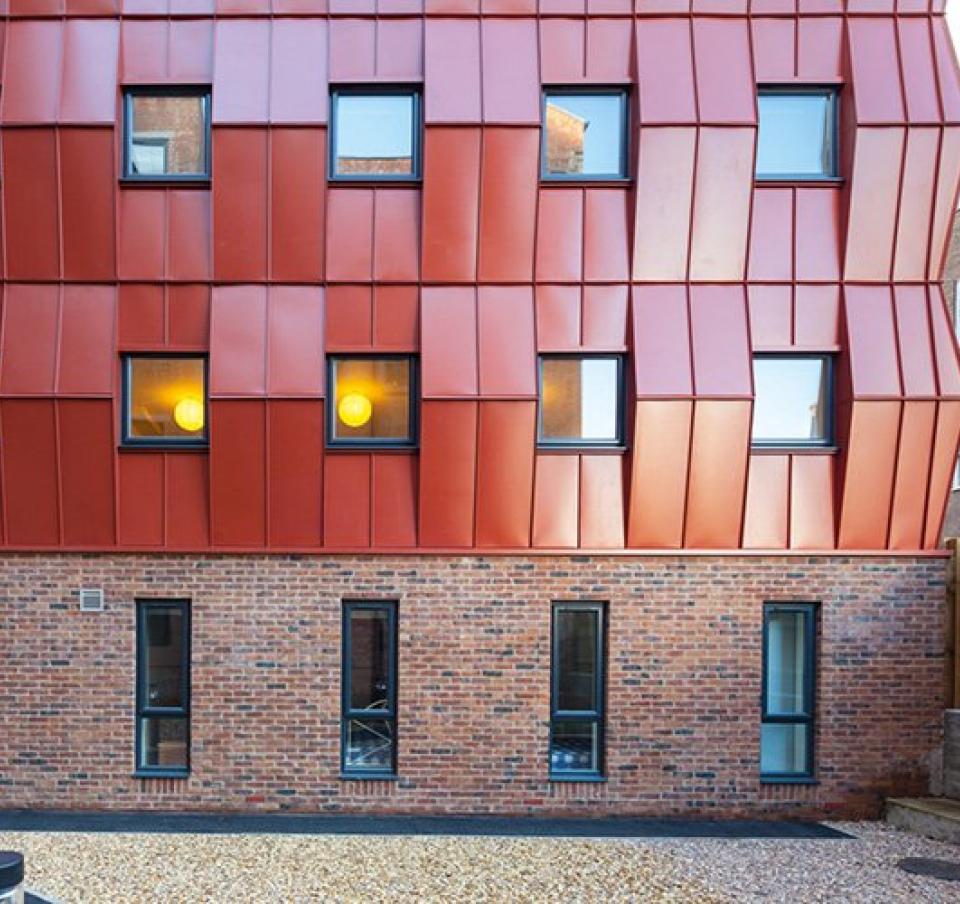

The structure was essentially sound and, known as the Shoe and Boot Factory, Willmore Iles Architects proposals were based around reviving the original building and enhancing it with modern extensions.

The redevelopment has provided 34 apartments (173 bedrooms in total) with students located in the original structure and key workers in the separate new-build elements, linked by landscaped gardens to create a calm retreat within the city centre.

The challenge

The task of cladding the new timber-framed extensions was to provide a visually strong form without introducing unnecessary complexity to the build. It was essential that the rain-screen cladding system selected could achieve the clean lines required by the proposed geometry as well as permitting any differential movement, and retain its bold look with the minimal need for maintenance.

The solution

Working closely with Tata Steel the project team chose to use approximately 600m2 of Colorcoat Urban®. The 514mm wide wall panels were supplied in Terracotta., which provided a striking façade which enhanced the concertina effect. The panels can be laid at virtually any angle down to a minimum of five degrees.

“While originally developed as a roofing product, we first looked closely at pre-finished steel and the Colorcoat Urban® system in mid-2012, to act as a potential alternative to composite board cladding products. Interestingly, our QS provided like-for-like supply-only cost estimates which showed that Colorcoat Urban® rates were more competitive than composite board materials,” says Julian Owen, Architect for Willmore Iles Architects.

Willmore Iles Architects worked with the Colorcoat Urban® technical design team to create the details necessary to achieve this adaptation, so that the sheet could be used as the outer element in a rain-screen cladding system. “Their willingness to co-operate in working through the details gave us confidence that the concept would become a reality,” adds Mr Owen.

The walls of the new timber extensions were clad on three sides in the Colorcoat Urban® panel. The one-off junction details at the base and heads of the changes in angle were part of the Colorcoat Urban® technical team’s solution, along with special details to window cheeks and sills, all supplied in the same colour-matched pre-finished steel to provide the clean detailing and clarity of aesthetic required.

Special pressed steel gutters were integrated into the package to give the contractor a one-stop solution to include all elements of the metal cladding, which greatly assisted the viability of the whole effort and blended seamlessly into the build.

EN-Construction-Contact-Urban

Call the Catnic® Urban team

Tata Steel

Shotton Works

Deeside Flintshire CH5 2NH

United Kingdom