Timmerhuis

Public sector case study, ComFlor®

Client: Ontwikkelingsbedrijf Rotterdam (OBR)/Heijmans Utiliteit

Architect: OMA (Office for Metropolitan Architecture)

Main contractor: Bouwbedrijf Heijmans N.V.

Consulting Engineer: Pieters Bouwtechniek

Decking Installer: Kempen Cladding B.V.

Tata steel products: ComFlor® 80, ComFlor® 60 and ComFlor® 210 (supplied by Tata Steel’s distributor Dutch Engineering r.i. B.V.)

Year: 2015

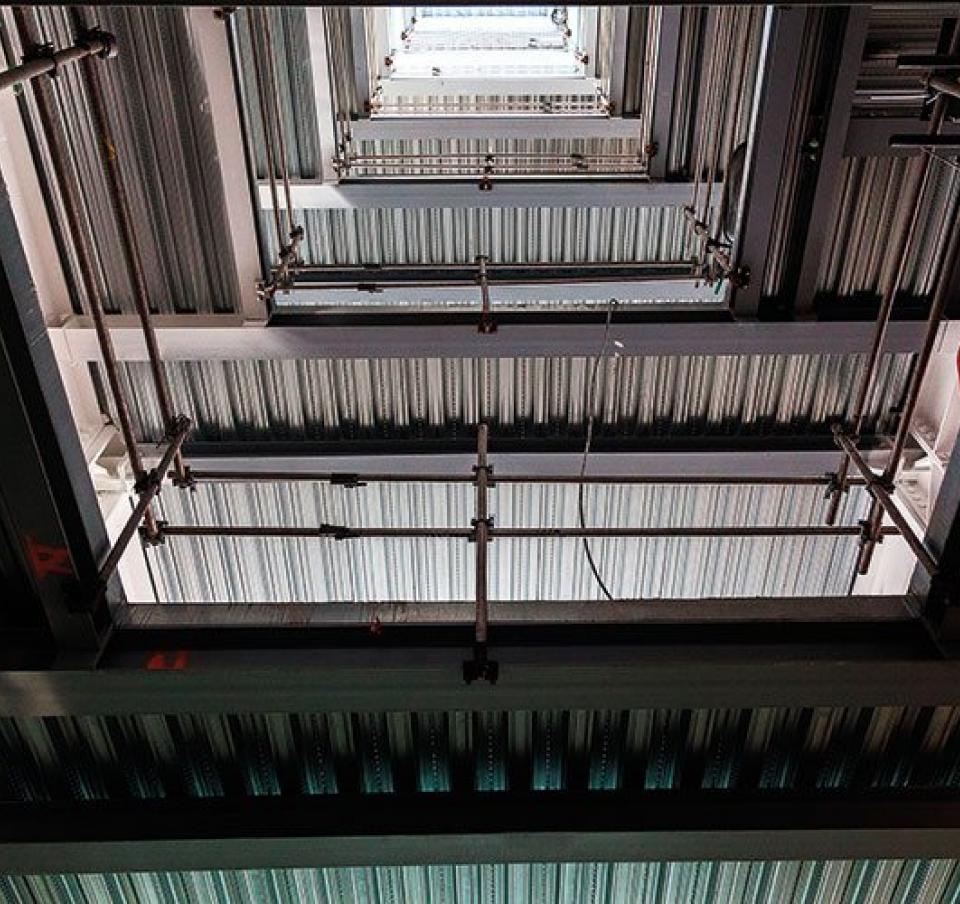

The Timmerhuis is a highly architectural steel-framed modular extension to Rotterdam’s city hall offices and the most sustainable multi-functional building in the Netherlands. The building is formed by a series of stacked cubes that are set back from the street and rise into two irregular peaks.

Conceived by the Office for Metropolitan Architecture the mixed-use building is composed of offices and residential units, and is said to create an impressive, complex form when viewed from Coolsingel, one of Rotterdam’s main arteries.

The challenge

The project’s design went through a rigorous sustainability assessment, starting with microclimate analysis. The building’s form was optimised for daylighting, thermal comfort, energy use and water conservation, achieving a BREEAM ‘Excellent’ Sustainability Certification.

The aim was to build with future flexibility in mind by creating a building that can be adapted to either office space or residential parameters as desired, or even total disassembly. Timmerhuis’s innovative structural system generates maximum efficiency and versatility both in construction and in programme, as units can be added or even dismounted from the structure as demands on the building change. Green terraces on higher levels provide the option of an apartment with a garden in the heart of Rotterdam.

Dutch Engineering had been involved from the early design stages, when Pieters Bouwtechniek and the architect were considering the various flooring options available on the market.

Speed and ease of construction were of the upmost importance to the project team and a flooring system that could easily be incorporated with the steel frame was vital to the design.

“A cost-effective flooring solution was required, one that would achieve long spans and the load requirement, with a low concrete volume, thereby removing the need for temporary propping,” explains Henk Prins of Dutch Engineering, Tata Steel’s distributor.

The solution

ComFlor® was the preferred flooring option out of five available flooring systems put forward, based on its light weight and cost.

“The design team’s comprehensive floor system evaluation required a flooring system that would fulfil the required design brief requirements. The build required a flooring system that provided strength, achieved the load and span requirements and one that offered a fast build at great height was not forgotten in this decision process,” adds Mr Prins.

The flooring solution was completed using 20,000m2 of ComFlor® 80 in 0.90mm and 1.20mm gauges, 5,000m2 of ComFlor® 60 in a 0.90mm gauge as well as 825m2 of ComFlor® 210 in a 1.00mm gauge.

Jan Neele, the Project Consultant for the flooring solution further explains the decision to use ComFlor®. “The system’s combined light weight attributes along with structural strength was vital on the cantilevering areas of the project.

“The compositely formed slabs were used in the composite design of the secondary beams, as lateral restraints for the beams and for the diaphragm action, which gave the steel frame its stability.

EN-Construction-Contact-BSUK - Structural

Building Systems UK technical team - Structural

Tata Steel

Shotton Works

Deeside Flintshire CH5 2NH

United Kingdom