Colorcoat Aquatite®

A life-times waterproofing - guaranteed

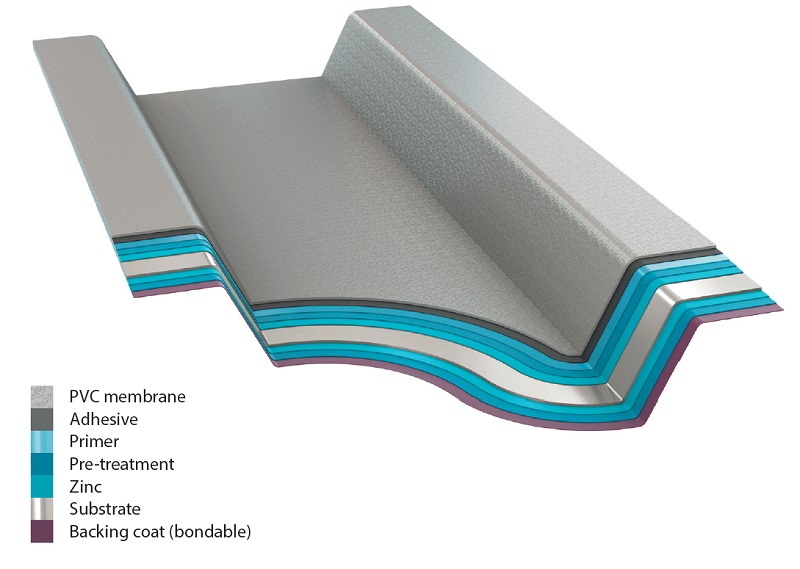

Colorcoat Aquatite® is a pre-finished steel for membrane rainwater systems. It consists of a tough 1.2mm PVC membrane that is factory-bonded to a galvanised substrate.

It combines to provide a watertight solution that can be used to manufacture fully sealed rainwater systems, guaranteed for 25 years. Available with a smooth or slip resistant emboss finish.

EN-Construction-Product-Colorcoat Aquatite-default

EN-Construction-Product-Colorcoat Aquatite | Overview

Specifically developed for industrial, residential, commercial and agricultural applications, the water resistant membrane offers the perfect, hassle-free rainwater management solution.

Suitable for gutters, flashings, roofing and parapet copings, the non-permeable membrane is available in a range of thicknesses.

Supplied with a smooth finish or our certified slip resistant emboss, Colorcoat Aquatite® provides excellent colour stability and resistance to UV light, heat, harsh weather conditions and general wear and tear.

Making the right choice matters

Colorcoat Aquatite® offers an unbeatable combination of a strong, formable metal substrate with a non-permeable weather resistant membrane factory-bonded to the water-carrying surface.

This highly effective construction gives a superior quality finish for maximum drainage efficiency. It comes with the reassurance of a leading guarantee and technical guidance on specification.

EN-Construction-Product-Colorcoat Aquatite | Dimensions

| Gauge | Width | Standard |

|---|---|---|

| 1.2mm | 1000mm (1m) | Yes |

| 1.2mm | 1250mm (1.25m) | Yes |

| 1.2mm | 1435mm (1.435m) | Yes |

| 1.5mm | 1000mm (1m) | Yes |

| 1.5mm | 1250mm (1.25m) | Yes |

| Length | ||

| Up to a maximum of 4.5m | ||

EN-Construction-Product-Colorcoat Aquatite | Key benefits

Key benefits

<ul> <li>Guaranteed for 25 years.</li> <li>Robust, highly durable 1.2mm non-permeable PVC membrane combined with a high performance 1.2mm or 1.5mm hot dip galvanized substrate to <br/>BS EN 10147.</li> <li>Available with a slip resistant emboss, independently tested and certified to BS 7976-2 for safer rainwater goods installation and maintenance.</li> <li>Factory-bonded to a Colorcoat<sup>®</sup> pre-finished steel substrate with bondable backing coat, for assured adhesion.</li> <li>Fire resistance performance tested to BS 476 Part 3 and ENV 1187 test 4. Achieves national class EXT.F.AB and European Class Broof(t4).</li> <li>Supplied as standard in grey, with excellent colour stability.</li> <li>Supplied in coil or flat sheet.</li> <li>Designed to form a sealed, water carrying surface, free from the reliance of additional bolts and sealants, providing a more visual aesthetic finish.</li> <li>Simple and easy to fabricate. Supplied with a choice of end to end butt strap or with a weldable flap to suit on-site welding, reducing installation time by 50%.</li> <li>PVC membrane can easily be hot air welded or chemically bonded.</li> <li>Available with Tata Steel’s Platinum<sup>®</sup> Plus building system guarantee, covering the entire envelope for up to 30 years.</li> <li>Available in small order quantities in lengths up to 4.5 metres.</li> <li>Limitless design possibilities, can be moulded effortlessly into a wide range of shapes to meet customer requirements.</li> </ul>

EN-Construction-Product-Colorcoat Aquatite | Technical guidance

Health & safety

Slips and trips are the most common cause of injury at work. On average, they cause over a third of all major injuries and over 40% of all reported injuries. HSE statistics suggest the most of these accidents are slips, most of which happen when walking surfaces are contaminated (water, talc, grease, etc).

Colorcoat Aquatite® has a unique trademarked emboss design for slip resistance, with sharp leading edges in all directions, ensuring a low slip risk classification both in wet and dry conditions.

This product has been independently tested and certified to BS 7976-2, in accordance with latest UKSRG Guidelines and current UK Health and Safety Executive guidance.

Slip resistance table:

| Direction | Condition | Classification |

|---|---|---|

| Principal | Dry | Low |

| 45° | Dry | Low |

| 90° | Dry | Low |

| Principal | Wet | Low |

| 45° | Wet | Low |

| 90° | Wet | Low |

Colorcoat Aquatite® PVC can be installed using established ‘single ply’ heat seaming techniques.

Welding Joints are straightforward and can be produced on-site using simple hot air welding techniques that give excellent watertight results. This also eliminates the need for mechanical fixings and sealants, which can be messy and costly, and it ensures that the finished installation looks, and remains looking good, for many years.

Colorcoat Aquatite® welding end to end process

Colorcoat Aquatite® flap welding process

EN-Construction-Product-Colorcoat Aquatite | Colorcoat Aquatite® guarantee

The Colorcoat Aquatite® 25 year guarantee applies to a specific building. It covers the membrane liner (excluding any joints) and offers suitable restoration in the event of any defects, providing complete peace of mind that your building will remain watertight for its life-span.

Guaranteeing the longevity of Colorcoat Aquatite® products on your building is simple and easy. The building owner will need to apply for the Colorcoat Aquatite® guarantee which can be done in one of two ways: - download and online.

Ways to register for your Colorcoat Aquatite® guarantee

What happens after registration

Following processing, Colorsteels will issue the guarantee to the specific building, complete with registration number.

Note: Colorcoat Aquatite® must be registered within three months of the building installation completion date for the guarantee to be valid.

Reduced risk for the life of the building

The guarantee applies to a specific building and is fully transferrable in the event of sale or transfer of ownership or tenant, providing a direct link back to Tata Steel.

EN-Construction-Product-Colorcoat Aquatite | Service support

To obtain a no-obligation, fully itemised estimate speak with one of our Colorcoat Aquatite® experts

Our team are on hand to provide estimates, samples and advice on the performance and most suitable system for your project. In addition our dedicated team can provide comprehensive support at every stage of your project.

For more information on Colorcoat Aquatite® or Colorsteels please contact:

Technical and General Enquiries:

T: +44 (0) 1244 892898

E: colorsteels@tatasteeleurope.com

EN-Construction-Product-Colorcoat Aquatite | Hand samples

Our hand samples can assist in colour selection and finalising product specification.

To order samples for Colorcoat Aquatite® call +44 (0) 1244 892881 or email colorsteels@tatasteeleurope.com

EN-Construction-Product-Colorcoat Aquatite-downloads

Downloads

<p></p>

EN-Construction-Datasheet-Colorcoat Aquatite Welding Datasheet

Colorcoat Aquatite® Welding Datasheet

EN-Construction-Contact-BSUK envelope

Building Systems UK technical team - Building Envelope