Tata Steel is ramping up activity at its UK structural steel distribution site at Redcar, Teesside, following completion of a second phase of development.

Teesside Service Centre, next to the company’s Teesside Beam Mill, is the only steel sections processing facility in the UK backed up by an adjacent production capability. Following installation of the last of the new processing equipment due on site, the new facility is looking to surpass its nominal 170,000 tonnes per year capacity in order to support increasing customer demand.

The centre’s extensive product range of sections, including structural hollow sections, serves a wide variety of construction and infrastructure projects from new schools, hospitals, sports complexes and large-scale distribution depots, to the iconic buildings that have transformed London’s skyline in recent years.

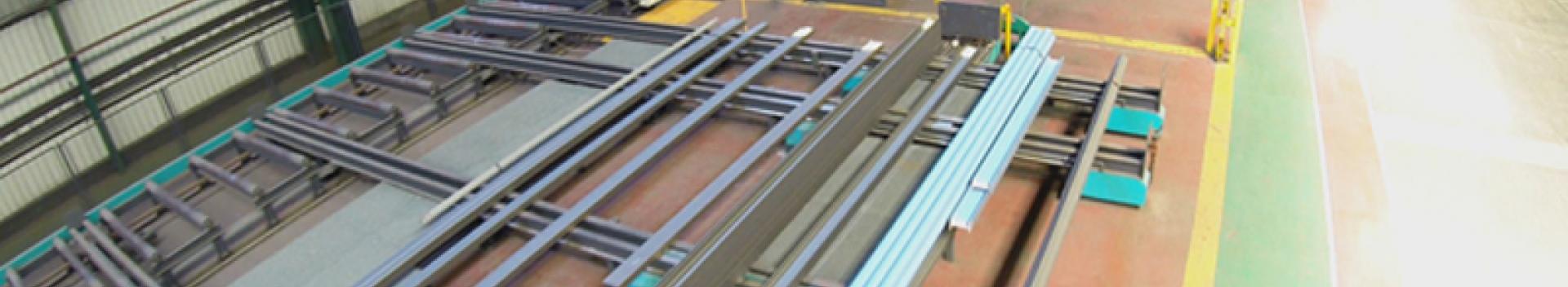

The specially designed site for Tata Steel’s UK sections distribution activities was established in 2012. Based around an existing warehouse on the Redcar plant site, a modern stocking facility was created with new handling and processing equipment. Outside stocking areas were reorganised and new access roads built. The breadth and depth of the stock range now available ensure that Tata Steel is better placed to service customer enquiries.

The latest developments have involved opening up another warehouse, and installing a high-specification shot-blaster and new heavy sections sawing capacity that has been located in order to reduce handling time and costs. Tata Steel has invested a total of £8.5 million in Teesside Service Centre.

The centre has five saws and is serviced by thirteen cranes, all designed with maximum operating and logistical flexibility to ensure timely despatch of customer orders.

Ian Beveridge, Tata Steel’s Director of Construction Structures, said: “We have established Teesside Service Centre to be able to offer customers a uniquely flexible service. The location at the end of a mill production line gives customers the option of buying ex-rolling or ex-stock. Furthermore, the investments we’ve made in logistics, new handling and processing equipment mean we’re able to offer a product and delivery service with unrivalled speed and efficiency. That all adds up to Teesside Service Centre being the leading distribution facility in the UK and the benchmark in our industry.”

Teesside Service Centre offers cutting-to-length, shot-blasting and priming (colour-coating). The centre’s entire operation is also fully compliant with all the new construction products regulations, including CE markings.

The centre employs 94 people, which includes about 40 new jobs created since the centre was established in 2012. The centre is responsible for managing and distributing steel from the Teesside Beam Mill, as well as Tata Steel’s sections mill in Scunthorpe, North Lincolnshire, and the company’s tubes mills in Corby,Northamptonshire.

-ends-

Contact for further information

Bob Jones, Global Head of PR & Media, +44 (0)207 717 4532 or bob.jones@tatasteel.com

About Tata Steel’s European operations

Tata Steel is Europe's second largest steel producer, with steelmaking in the UK and Netherlands, and manufacturing plants across Europe. The company supplies products and services to the most demanding markets, including construction, automotive, packaging, rail, lifting & excavating, energy & power and aerospace. The combined Tata Steel group is one of the world’s largest steel producers, with a steel capacity of 29 million tonnes and 80,000 employees across four continents.