The UK will need more than 10 million tonnes of steel over the coming years¹ to become more energy self-sufficient, according to new figures published today.

The UK Government set out plans to secure ‘clean and affordable’ energy in its Energy Security Strategy earlier this year. Achieving greater self-sufficiency has become vital after global events led to rocketing energy prices and significant government interventions in the energy market to cap prices.

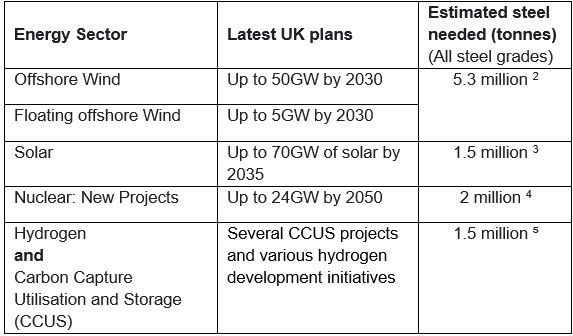

New research¹ from Tata Steel – the country’s largest steel producer – reveals more than 5 million tonnes of steel will be needed to build thousands of wind turbines at sea by 2030. Planned solar and nuclear power plants which would power future Britain are expected to require about 3.5 million tonnes of steel over the coming years.

An estimated 1.5 million tonnes of steel will be needed to build the infrastructure for hydrogen production and distribution as well as large-scale carbon capture (CCS) projects. And the metal will also be needed to unlock new sources of oil and gas from the North Sea.

Henrik Adam, Chairman of Tata Steel UK, said: “Recent events have shown us just how crucial it is to have a secure energy supply. Achieving this will need an energy revolution in this country requiring millions of tonnes of steel to build new energy generation projects.

“UK steelmakers, like Tata Steel, want to be part of this revolution, such as by developing new steel products for solar farms or for floating offshore wind structures. A strong domestic and secure steel industry is also fundamental to delivering the UK Government’s ambitious energy plans.

“But if British manufacturers are to supply the essential steel and continue to employ many thousands of people in this country, we need to invest and transform this strategically-important industry so it can make carbon-neutral steel.

“We need to learn the lessons from the UK’s energy supply which, as the Government says, ‘drifted into dependence on foreign sources’, undermining the country’s energy independence.

“Similarly, our steel industry is at a crossroads – if we do nothing, we risk it declining and drifting away to other countries. Down the other path is a new era in which we transform the steel production process to make it fit for the 21st Century.”

Henrik added: “Geo-political events and disruptive trade issues in recent years have reminded us of the importance of being self-sufficient in essential products like steel, a product critical for the UK’s infrastructure projects, manufacturing industry and national security.”

Roy Rickhuss CBE, General Secretary of Community and NTUSCC Chair, said: “The green energy revolution presents a huge opportunity to build a robust British supply chain based on the supply of top-quality domestic steel. The events of the last two years tell us Britain cannot rely on fragile global supply networks for strategic goods, and if we want to go green it is nonsensical to transport steels from the other side of the world.

“Not only will using Britain’s steel be crucial to meeting our climate objectives, it will support thousands of good jobs and steel communities across the country. Steelworkers look to the government to support investment in green steel and do more to ensure that British jobs benefit from taxpayer-backed energy projects.”

Gareth Stace, Director General of UK Steel, said: “These numbers clearly demonstrate the huge opportunity the energy transition represents not just to reduce emissions but to boost the UK economy, UK manufacturing and the UK steel sector.

“The UK already has the largest offshore wind sector in the world, but with a target to increase capacity by 400% this decade we are only just getting started. Opportunities have been missed in the past to establish a full UK supply chain for this sector, but with so much growth still in front of us, this is the time to get this right. Similar opportunities exist in our expansion of nuclear, solar and the roll-out of CCS and hydrogen networks.

“The UK steel industry is in a prime position to supply the steel for this new UK energy infrastructure and doing so will help maximise the jobs and economic growth the energy transition can deliver for the UK.

“Today, our sector employs 33,700 people directly and supports a further 42,000 indirectly through its purchase of goods and services, with most jobs concentrated in Yorkshire & the Humber region, and Wales where steel wages are 59% above the regional average. Producing UK energy from UK steel is the green industrial revolution in practice, creating green jobs, economic growth and levelling up.”

ends

Notes to Editor:

¹ Steel figures are a combination of Tata Steel’s market intelligence and published data.

Notes about amount of steel needed:

2 Steel volume data sourced from UK Government’s steel public procurement pipeline (June 2022)

3 Estimate based on 28 tonnes of steel needed to build 1 megawatt of solar energy.

4 Estimate based on about 100,000 tonnes of steel needed to build 1 gigawatt of nuclear energy.

5 Estimate based on Tata Steel’s market intelligence about the UK’s project pipeline. One element of that pipeline is an ambition to build up to 10GW of hydrogen production by 2030, as stated by the UK Government in its Energy Security Strategy

For further information: Tim Rutter on +44 (0)7850 990755 or tim.rutter@tatasteeleurope.com

About Tata Steel UK

- The Tata Steel Group has been named one of the most ethical companies in the world, and is among the top producing global steel companies with an annual crude steel capacity of 34 million tonnes.

- Tata Steel in the UK has the ambition to produce net-zero steel by 2050 at the latest, and to have reduced 30% of its CO2 emissions by 2030.

- Tata Steel is the largest steelmaker in the UK with primary steelmaking at Port Talbot in South Wales supporting manufacturing and distribution operations at sites across Wales, England and Northern Ireland as well as Norway, Sweden, France and Germany. It also benefits from a network of international sales offices around the world.

- Tata Steel employs more than 8,000 people and has an annual crude steel capacity of 5 million tonnes, supplying high-quality steel products to demanding markets, including construction and infrastructure, automotive, packaging and engineering.

- Tata Steel Group is one of the world's most geographically-diversified steel producers, with operations and a commercial presence across the world.

- The Group recorded a consolidated turnover of US $32.83 Bn in the financial year ending March 31, 2022.

Follow us