Enhanced durability and high performance

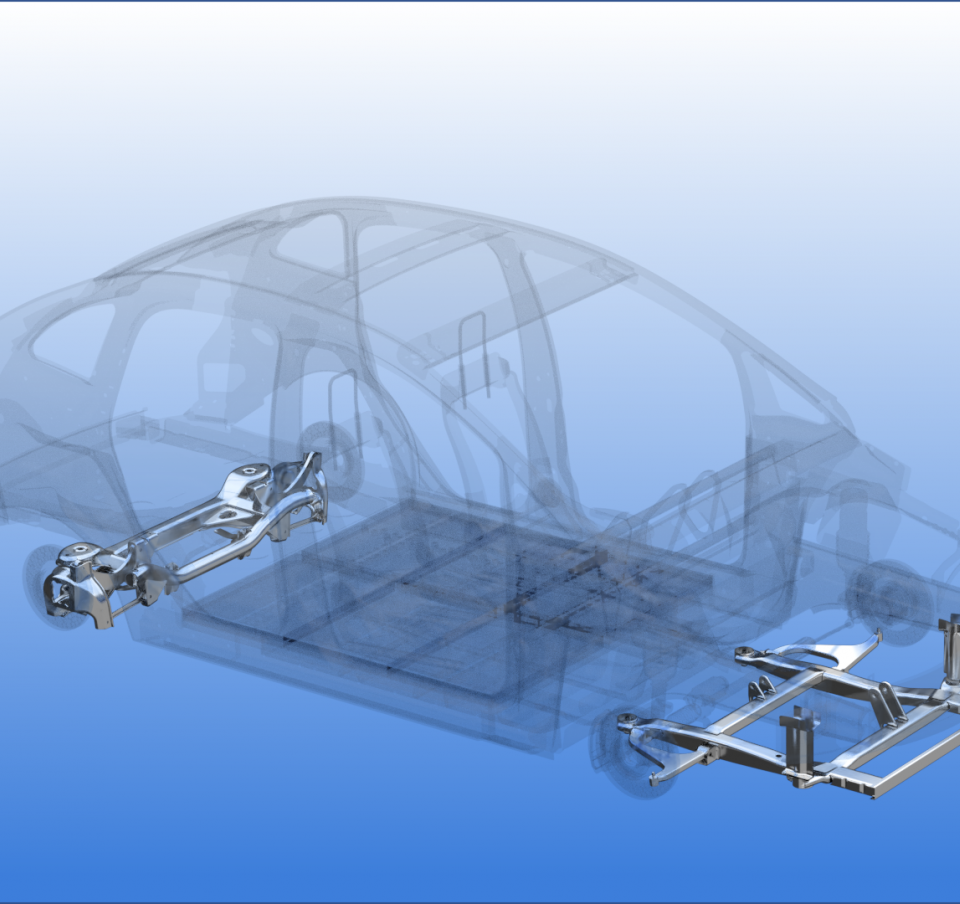

Meeting car safety regulations as well as CO2 emission targets poses challenges for both component design and the choice of material being used. Reducing the weight of a component by downgauging will affect other important performance characteristics such as stiffness, strength and fatigue. This has an influence on the car’s handling, safety and durability performance.

The increased focus on sustainability and the migration to battery electric vehicles (EVs) is having an impact on the chassis design. Designers must address durability and safety issues, along with weight savings for improved fuel economy and reduced emissions, while coping with the much heavier vehicle weight for EV. In addition, the constraints of the vehicle package space dictate complex component geometries. Steel remains to be the key material of choice. Our chassis experts support you to strike the balance.

Unlocking the potential of steel

Our hot-rolled advanced high-strength steel (AHSS) products and supporting services deliver:

- maximised ligthweighing potential with improved corrosion protection

- improved processabiblity of challenging parts

- a complete portfolio of steels delivered to your doorstep

- expert knowledge supporting you get the maximum out of our steel.

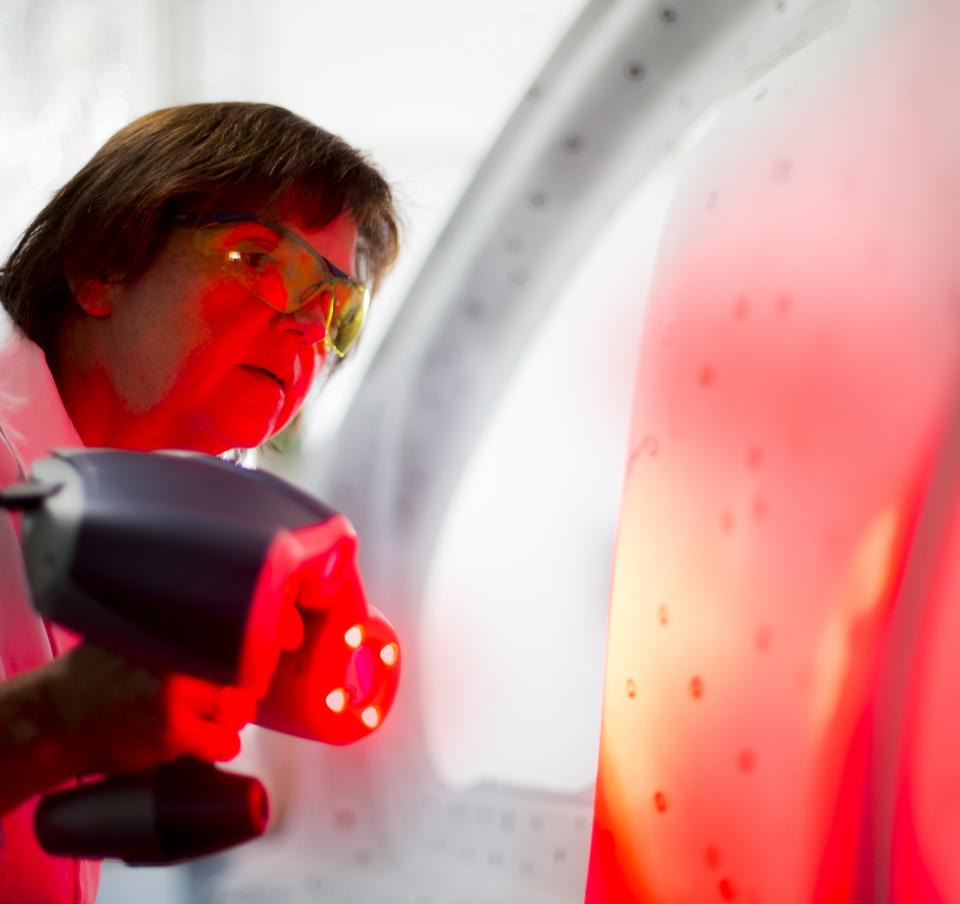

Can you downgauge without corrosion risk?

We believe that our formability-enhanced steels, such as XPF and complex-phase HHE (high hole expansion), have the potential to unlock huge lightweighting - enabling the use of higher strength steel in more components. Improved fuel economy and reduced CO2 emissions lie at the heart of the development of lightweight components. Designers are seeking thinner gauge steels that can also meet tough performance requirements.

Outstanding corrosion protection can open the door to further component lightweighting. The availability of hot-rolled AHSS with a metallic coating enables downgauging potential without additional corrosion risk.

Expert support for your choices

The chassis and suspension system must resist a wide range of impact loads – at front, side and rear to provide the required safety and performance. Now and in the future.

Our AHSS in 800 MPa and 1000 MPa combine strength with good ductility. Our material and applications experts can help support to translate our material characteristics into tangible benefits in use.

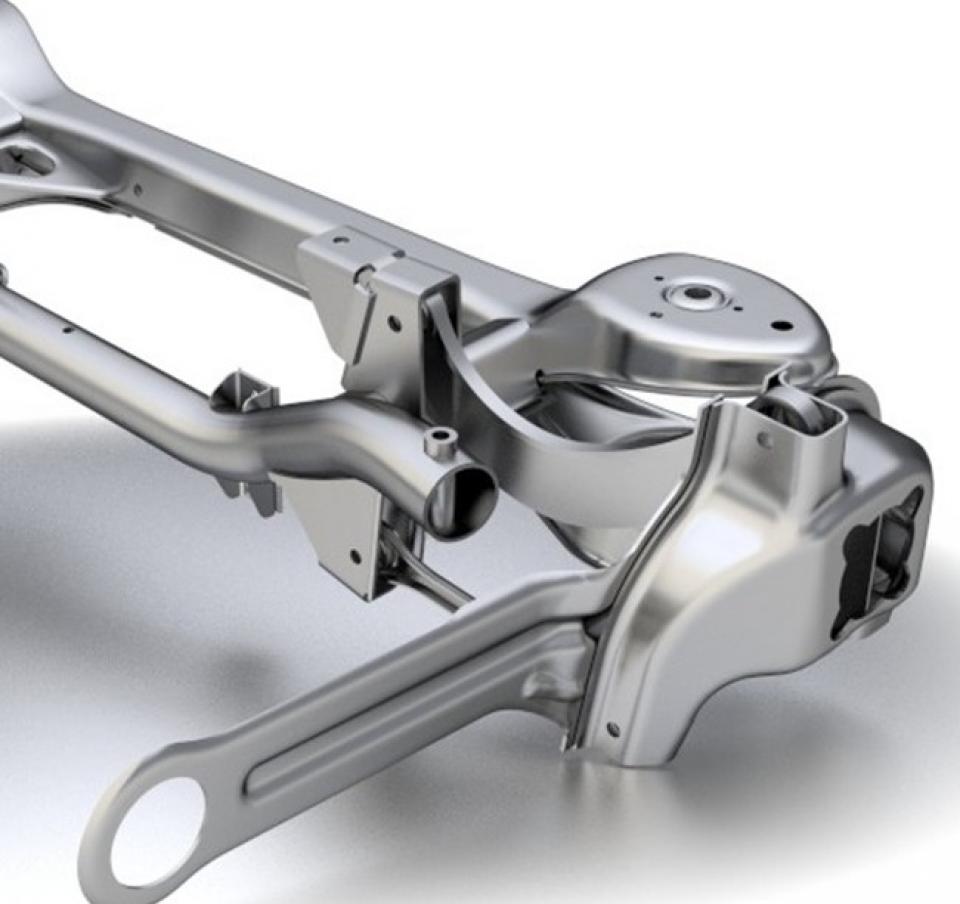

Smooth processing on challenging parts

Tighter packaging spaces and high stiffness requirements combined with high strength materials can make production more challenging. Our CP800 HHE and XPF products guarantee both high strength with excellent formability. Along with other important processing parameters such as product robustness and weldabilty, they ensure smooth processing of the most challenging parts.

Our ready to use CAE input decks tailored to our products properties provide accurate predictions on makeabilty.

A complete portfolio of steels and grades

We offer a wide range of hot-rolled and galvanised steels for chassis and suspension components. These aid the design of lightweight and cost-effective components without compromising performance.

A portfolio of HSLA, uncoated boron, advanced complex-phase grades and the newest high performance XPF family covers a complete range for all chassis and suspension applications. They deliver the stiffness, strength, formability and weldability needed for reliable performance and cost-effective processing.

Our material experts are there to support the deployment of our products in your specific application area. For more information contact our chassis and suspension experts.

Steel service centres and support near you

We supply our advanced steel grades across the globe. In Europe we have an extensive network of steel service centres that provide services to you locally. We also support customer programmes across the globe including the Americas and Asia. We supply:

- wide coil directly from the mill

- slit coil and blanks via our service centres network.

Tubular Chassis Parts

Most of our grades are also available as precision tubes. Our dedicated automotive service centres have a lot of experience with tubular chassis applications and can provide you with tubes that can be immediately processed further.

Expertise to lower your total cost of ownership

Tata Steel supports the car industry with advanced engineering services to fully exploit the benefits of advanced steels. We have extensive chassis and suspension application knowledge and services to identify cost- and weight saving opportunities to lower your total cost of ownership (TCO).

Our TCO Scans identify and quantify the TCO reduction potential that our advanced steel products offer your specific processes and applications. TCO Scans can be used both on an existing part where the emphasis is on improving production performance and on new parts yet to start production.

For more information contact our chassis and suspension experts.

Our materials database Aurora® Online, gives you fast and easy access to reliable material data. The cutting edge database contains comprehensive, up to date material files, data sheets and ready to run input decks, enabling you to set up accurate, reliable simulations.