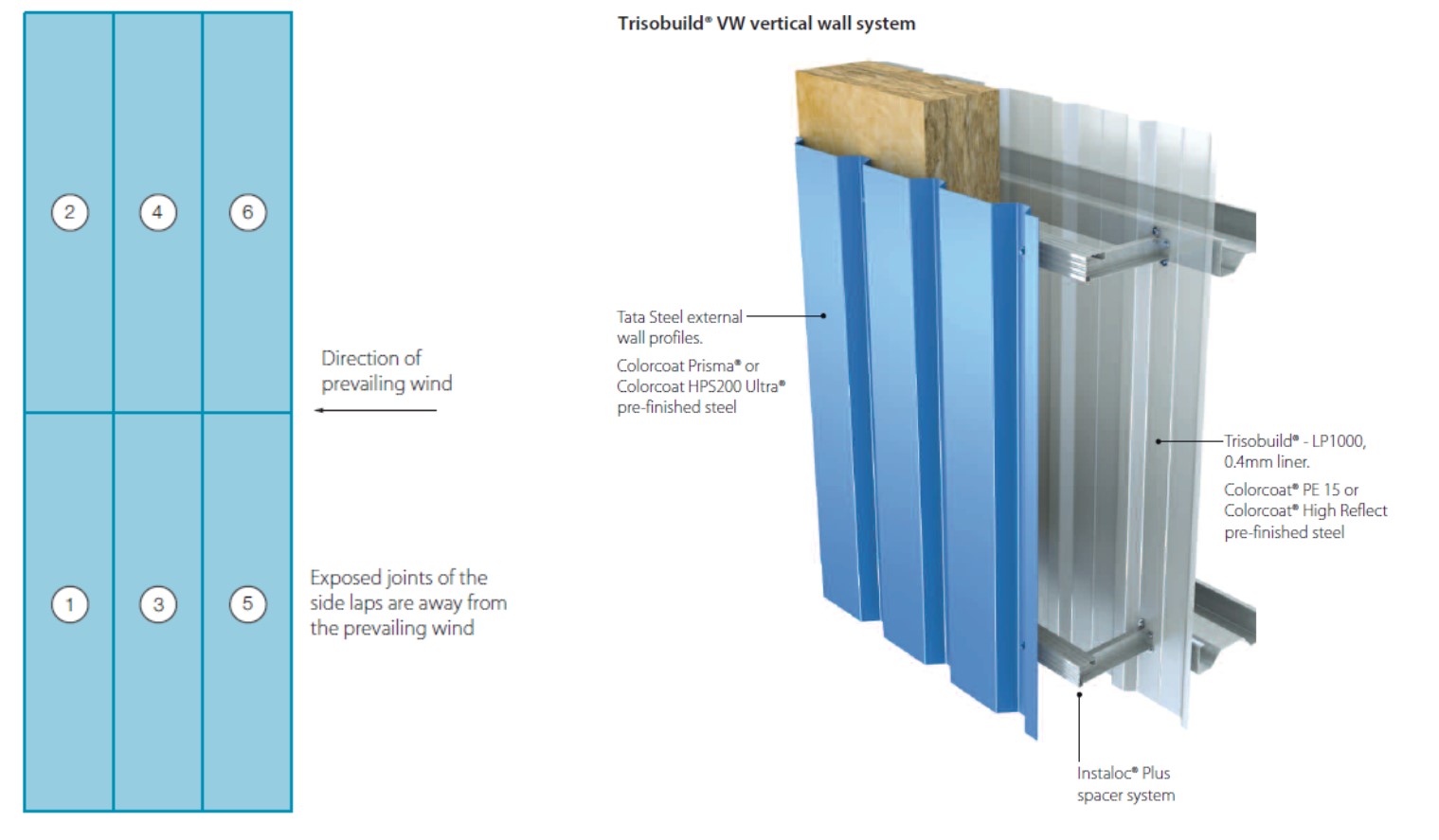

Trisobuild® built-up systems offer greater design flexibility and can be installed vertically or horizontally. There are however differences in the supporting rail arrangement methods to support each orientation. This blog provides guidance on how to install a vertical cladding with liner sheets in tiers using a horizontally laid Instaloc® Plus spacer system.

Standard installation guidance for installing Trisobuild® vertically

The steps given below are instructions for a typical construction and should be used only as a guide. Specific technical details, method statements and site-specific risk assessments should be produced and applied for each building. An extended list of construction details is available from Tata Steel, and advice can be given via our Technical Department on any bespoke details that may be required.

- Firstly, checks should be carried out to make sure that all horizontal rails are adequately supported and level along their full length, before commencing installation work. If this is satisfactory, carry out preparation work on cill trims and internal corner flashing etc. and ensure these are lined, levelled and sealed as specified.

- Install the liner sheets in tiers over part or all of the elevation, ensuring alignment and cover is maintained. Seal liner laps as shown on page 46 of our updated Trisobuild® brochure and ensure that sheet ends are closed and sealed using profile fillers.

- Lie out the Instaloc® Plus spacer system on the floor using 3.6m bars and ensure brackets are positioned at specified centres and adjacent to liner troughs. Install the spacer system along the horizontal rail line ensuring level is maintained.

- The insulation and external sheet should be laid in sequence from one corner of the

- building elevation so that wherever possible the exposed joints of the side laps are away from the prevailing wind. The sheeting should be installed in the sequence shown above.

- Before installing the insulation, ‘stick pins’ should be positioned to the liner face at mid span, and then the insulation should be draped from the eaves and tucked behind the horizontal spacer system and over the ‘stick pins’ so that it is held in place. Each tier of insulation should be compressed tightly with the previously one to make certain there are no gaps. If there are two layers of insulation; the joints in each layer should be offset.

- The end and side laps of the external sheet should be sealed as specified on page 46 of our updated Trisobuild® brochure and external vented fillers should be use where the sheets are discontinuous. Advice should be obtained from our Technical Department on fastener frequency, as this will depend on the calculated wind load for the cladding.

Further information on our range of Trisobuild® systems and construction details for installing Trisobuild® systems vertically can be found in our Trisobuild® brochure

Please contact our Technical Department for further advice or for an extended list of construction details on horizontal wall installation or use our online specification tool to help you create the right specification for the performance that suits the needs of your project. Doing this will give you peace of mind that cladding components are compatible and perform together as a system.