Cutting-edge digital technology, which captures 1,000 data points every 10 seconds, is giving Tata Steel technicians an uninterrupted 3D view of the material being laid into the top of its two Port Talbot blast furnaces saving costs, energy and CO2.

The market-leading ‘Topscan’ technology has the potential to reduce costs by lowering the amount of coke required in the furnaces, and will reduce CO2 emissions by at least 50,000 tonnes annually. The technology will also play a major role in improving the furnaces’ stability and efficiency.

Tata Steel UK has the ambition to reduce all CO2 emissions by 30% by 2030 and be a CO2 neutral steelmaker by 2045 – in support of the UK’s ambition to be net-zero by 2050.

Recently the company announced it is to formally adopt Science Based Targets with respect to its programme of emission reductions and carbon neutral steelmaking aspirations. It has been working on a number of projects to reduce CO2 emissions which can now be passed on to customers in the form of certificates allowing them to make Scope 3 emissions savings.

Called Optemis Carbon Lite, the certificate-based insetting scheme - verified by external third party assurance organisation DNV - is a flexible offering allowing customers to choose the CO2 intensity reduction they need.

Blast Furnace Technical Manager, Aaron Parsons, said: “This latest £1million investment on Blast Furnace 5 complements a similar investment last year on Blast Furnace 4 and is a major step forward for us.

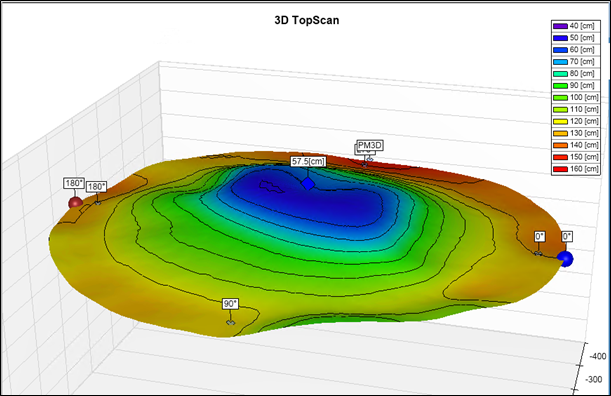

“The Topscan system consists of a set of radars which take a full surface scan of the iron ore and metallurgical coke being laid into each furnace, every 10 seconds. Computer modelling then gives us a really clear, finite view of the raw materials at the start of their journey through the furnace.

“That’s really important to us because the specific way in which we lay materials in the furnace is our main method of controlling gas flow up from the hot air blast through the raw materials.

“Over time, we can make tweaks to the distribution allowing us to make the most efficient use of the hot gases and yield really big savings, both in terms of coke usage and CO2.”

The state-of-the-art unit is very similar to the technology commissioned on Blast Furnace 4 last year, which is already delivering invaluable insights and big cost savings and CO2 reductions.

Aaron continued: “This is a big project for us -and a really important one -as it’s a massive upgrade from the seven static radars we had previously, from which we had to make assumptions to get a complete picture.

“Topscan is taking approximately 1,000 data points every 10 seconds, so it’s a real quantum leap forward in terms of the data and measurement. Changes to the burden that previously would have taken weeks to analyse and implement can now be done in a matter of hours.”

The installation of Topscan into Blast Furnace 5 is expected to be complete by end November 2022.

ends

NOTES:

- Blast Furnace 5 underwent a life-extension project in 2018. Watch the videos of the project here

- Blast Furnace 5 has 10.8m hearth diameter and 2134m3 working volume

- Blast Furnace 5 makes around 6000 tonnes of pure iron a day

- Topscan is the name of the monitoring instrument; it’s made by a company named TMT.

- CO2 savings come from the more efficient use of coke and hot blast gas to reduce the iron ore to iron

For further information: Tim Rutter on +44 (0)7850 990755 or tim.rutter@tatasteeleurope.com

Nathan Morris, Electrical Engineer overseeing the installation of the Topscan digital data scanner at Port Talbot’s Blast Furnace 5.

About Tata Steel UK

- The Tata Steel Group has been named one of the most ethical companies in the world, and is among the top producing global steel companies with an annual crude steel capacity of 34 million tonnes.

- Tata Steel in the UK has the ambition to produce net-zero steel by 2050 at the latest, and to have reduced 30% of its CO2 emissions by 2030.

- Tata Steel is the largest steelmaker in the UK with primary steelmaking at Port Talbot in South Wales supporting manufacturing and distribution operations at sites across Wales, England and Northern Ireland as well as Norway, Sweden, France and Germany. It also benefits from a network of international sales offices around the world.

- Tata Steel employs more than 8,000 people and has an annual crude steel capacity of 5 million tonnes, supplying high-quality steel products to demanding markets, including construction and infrastructure, automotive, packaging and engineering.

- Tata Steel Group is one of the world's most geographically-diversified steel producers, with operations and a commercial presence across the world.

- The Group recorded a consolidated turnover of US $32.83 Bn in the financial year ending March 31, 2022.

Follow us