Tata Steel UK has officially begun the decommissioning of its Morfa Coke Ovens after almost half a century of coke production in Port Talbot ceased yesterday.

Coke was produced for the last time ever in the UK on Wednesday 20 March at the South Wales plant, where a second-generation steelworker had the honour of making the final ‘push’ at 10:47.

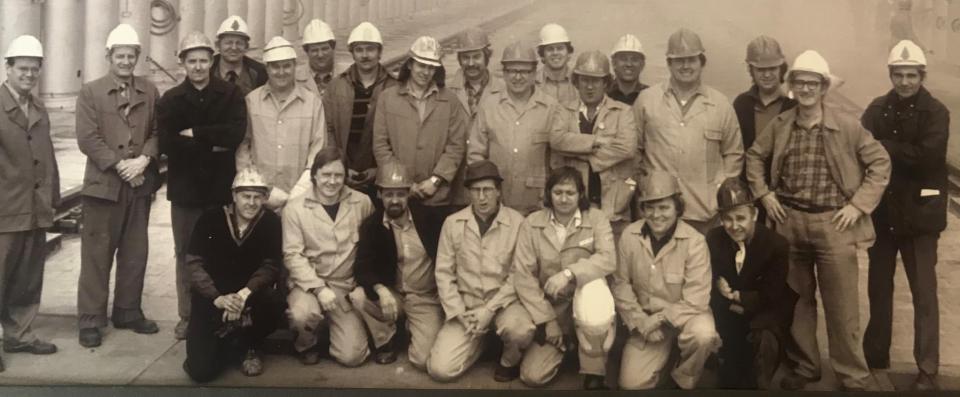

Terry Leyshon, who has worked at the site since 1979, pulled the lever for the final time on Battery 1, Oven 38, four decades after his father marked the commissioning of the ovens in 1981 with its first ever ‘push’.

Tata Steel UK CEO Rajesh Nair said: “While the end of operations was expected, after four decades of operation it was of course a sad day and I feel privileged to have been present.

“There is still much to do to make sure the coke ovens are brought to a close safely and securely, and to cease operations at the adjoining By-Products plant.

“My thanks go to the entire team, both front of house and in supporting roles, for their professionalism, composure, dedication and meticulous planning - the operation was executed safely and to plan.”

Works Manager Coke Sinter and Iron, Dean Cartwright, said: “It has been a very difficult day, but credit to the team who have been first class – I couldn’t have asked for more.

“It’s true that all things must come to an end, and while this reality is difficult to digest, today, the plant’s deteriorating performance has given us no choice but to cease operations at the ovens and its adjoining By-Products plant.”

“We celebrated our 1.5 millionth ‘push’ in 2021 and now we have marked our final one, having produced around 40 million tonnes of coke to feed our blast furnaces.

“Morfa Coke Ovens has been a special place to work for many people over the past 43 years and it has been a real privilege to be part of this loyal, professional and dedicated team.

“Generations of the same families at have worked here – fathers and uncles working alongside sons, daughters, nieces and nephews – all of which helped create an incredible community spirit.”

NOTES:

Tata Steel is investing £1.25 billion in electric arc furnace technology, which will secure steel making in Port Talbot for the long term —and facilitate a transition to low-CO2 steelmaking. Consultation on these aspects is currently ongoing.

For further information, please contact:

Tim Rutter, Head of PR, Tata Steel UK on tim.rutter@tatasteeleurope.com or +44 (0)7850 990755

Abi Thomas, PR & Social Media Specialist: abigail.thomas@tatasteeleurope.com

Press Office: ukpressoffice@tatasteeleurope.com

Further images of Morfa Coke Ovens can be found here.

- The Tata Steel Group has been named one of the most ethical companies in the world, and is among the top producing global steel companies with an annual crude steel capacity of 34 million tonnes.

- Tata Steel in the UK has the ambition to produce net-zero steel by 2045 at the latest, and to have reduced 30% of its CO2 emissions by 2030.

- Tata Steel is the largest steelmaker in the UK with primary steelmaking at Port Talbot in South Wales supporting manufacturing and distribution operations at sites across Wales, England and Northern Ireland as well as Norway, Sweden, France and Germany. It also benefits from a network of international sales offices around the world.

- Tata Steel employs more than 8,000 people and has an annual crude steel capacity of 5 million tonnes, supplying high-quality steel products to demanding markets, including construction and infrastructure, automotive, packaging and engineering.

- Tata Steel Group is one of the world's most geographically-diversified steel producers, with operations and a commercial presence across the world.

Follow us on social media